When a cylindrical object is subjected to a twisting force, it experiences torsion. The torsional modulus of elasticity, also known as the shear modulus or modulus of rigidity, is a measure of a material’s resistance to twisting and shear deformation under torsional stress.

This key material property is essential for engineers and researchers working with shafts, beams, and other structures that undergo torsional loading.

In this article, we will explore the concept of torsional modulus of elasticity, its significance, measurement techniques, and real-world applications.

Keywords: torsional modulus of elasticity, shear modulus, modulus of rigidity, torsion, shear deformation, torsional stress

Torsional Modulus of Elasticity: A Key Mechanical Property

The torsional modulus of elasticity, also known as the shear modulus or modulus of rigidity, is a critical property that describes a material’s response to shear stress and its resistance to shearing deformation.

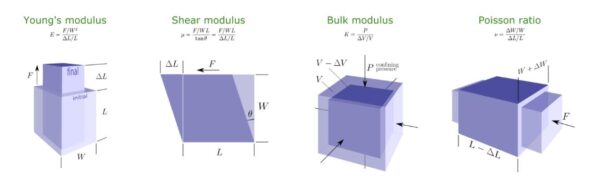

This modulus is one of the fundamental elastic moduli used in analyzing the mechanical properties of materials and their ability to withstand forces applied in a twisting manner without undergoing permanent deformation.

Keywords: torsional modulus of elasticity, shear modulus, modulus of rigidity, mechanical properties, elastic moduli

Definition and Fundamentals of Shear Modulus

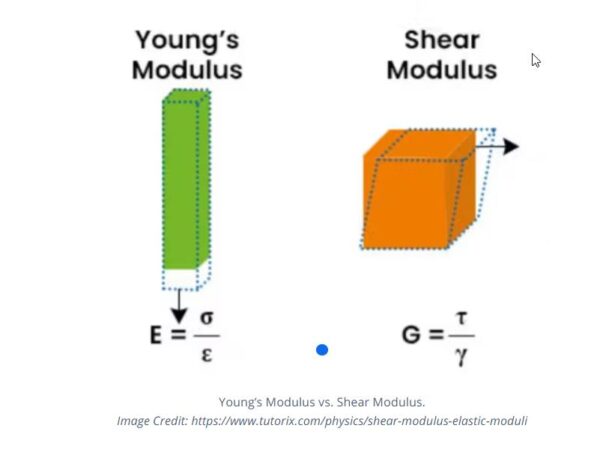

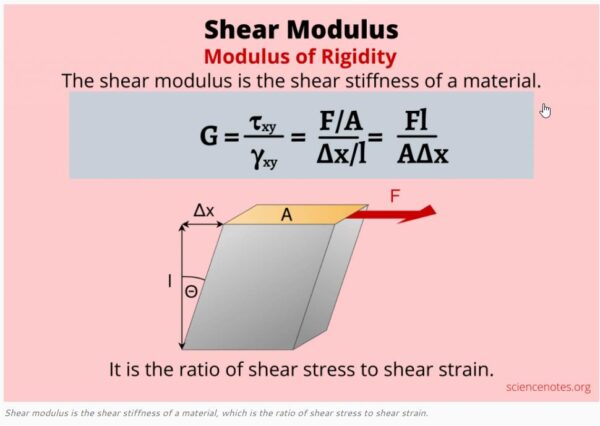

The torsional modulus of elasticity (G) is defined as the ratio of shear stress (τ) to shear strain (γ) within the elastic limit of a material[1]. It is expressed by the equation:

G = τ / γ

Where:

– G is the torsional modulus of elasticity (Pa or N/m²)

– τ is the shear stress (Pa or N/m²)

– γ is the shear strain (unitless)

Shear stress is the force per unit area acting parallel to the cross-section of the material, while shear strain is the angular deformation caused by the shear stress. The torsional modulus is an intrinsic property of a material and is dependent on the atomic and molecular structure of the substance[2].

Keywords: shear stress, shear strain, elastic limit, angular deformation

Definition and Relationship to Young’s Modulus

The torsional modulus of elasticity is defined as the ratio of shear stress to shear strain within a material’s elastic limit.

It is a measure of the material’s stiffness and resistance to shear deformation. The shear modulus is typically expressed in units of pascals (Pa), gigapascals (GPa), or pounds per square inch (psi).

The torsional modulus is related to Young’s modulus, another essential elastic modulus that describes a material’s response to tensile or compressive stress. For isotropic materials, the relationship between the shear modulus (G) and Young’s modulus (E) is given by:

G = E / (2 * (1 + ν))

where ν is Poisson’s ratio, a material property that characterizes the lateral contraction of a material when subjected to tensile stress.

Keywords: shear stress, shear strain, elastic limit, Young’s modulus, Poisson’s ratio

Significance in Modulus of Rigidity in Engineering

The torsional modulus of elasticity plays a crucial role in the design and analysis of various engineering components and structures. It is particularly important for:

1. Shaft design: The torsional modulus determines the amount of twisting a shaft will experience under a given torque. A higher torsional modulus indicates that the material is more resistant to twisting, which is desirable for power transmission shafts, drive shafts, and propeller shafts[3].

2. Structural integrity: Torsional rigidity is essential for maintaining the structural integrity of beams, bridges, and other load-bearing structures subjected to torsional stresses. A material with a high torsional modulus will be less likely to fail due to twisting or shear deformation[4].

3. Material selection: Knowledge of the torsional modulus helps engineers select appropriate materials for specific applications. For example, materials with high torsional moduli, such as steel and titanium alloys, are preferred for high-performance applications where torsional rigidity is critical[5].

Keywords: shaft design, power transmission, structural integrity, torsional rigidity, material selection

Measurement Techniques

There are several methods for measuring the torsional modulus of elasticity, including:

1. Torsion testing: In this method, a cylindrical specimen is subjected to a known torque, and the resulting angular deformation is measured. The torsional modulus can then be calculated using the applied torque, specimen dimensions, and angular deformation[6].

2. Resonance method: This non-destructive technique involves measuring the natural frequency of torsional vibrations in a specimen. The torsional modulus is determined by the specimen’s density, dimensions, and the measured resonant frequency[7].

3. Ultrasonic method: Ultrasonic waves are used to measure the velocity of shear waves propagating through a material. The torsional modulus can be calculated from the shear wave velocity and the material’s density[8].

Keywords: torsion testing, resonance method, ultrasonic method, non-destructive testing

Factors Affecting Torsional Modulus

Several factors can influence the torsional modulus of a material, including:

1. Composition: The chemical composition and microstructure of a material significantly affect its torsional modulus. For example, the addition of alloying elements can alter the torsional modulus of metals[9].

2. Temperature: The torsional modulus of most materials decreases with increasing temperature due to changes in the atomic and molecular bonding[10].

3. Strain rate: The rate at which torsional stress is applied can influence the measured torsional modulus. Higher strain rates generally result in higher apparent torsional moduli[11].

Keywords: composition, microstructure, alloying elements, temperature dependence, strain rate

Real-World Applications

Torsional modulus is a critical parameter in various engineering applications, such as:

1. Automotive industry: Drive shafts, half shafts, and torsion bars in vehicles are designed with materials having high torsional moduli to ensure efficient power transmission and durability[12].

2. Aerospace engineering: Aircraft components, such as propeller shafts and turbine blades, require materials with high torsional rigidity to withstand the extreme torsional stresses encountered during operation[13].

3. Civil engineering: Bridges, buildings, and other structures must be designed to resist torsional loads caused by wind, earthquakes, and asymmetric loading. Materials with high torsional moduli are essential for ensuring structural stability[14].

Keywords: automotive industry, drive shafts, aerospace engineering, propeller shafts, civil engineering, structural steel

Importance in Material Selection and Design

The torsional modulus plays a crucial role in selecting materials for applications that involve twisting deformation, such as spring materials, drive shafts, and torsional vibration dampers.

A higher shear modulus indicates that a material has a greater resistance to shearing and is less likely to deform under torsional loads.

Engineers and designers must consider the torsional modulus when analyzing the mechanical properties of materials and determining their suitability for specific applications.

By understanding a material’s response to shear stress and its ability to withstand twisting deformation, engineers can make informed decisions about material selection and design optimization.

Keywords: spring materials, twisting deformation, resistance of a material, analyzing the mechanical properties, ability of a material

Measurement and Typical Values

The torsional modulus can be measured using various techniques, such as torsional pendulum tests, resonance methods, or by applying a known torque to a cylindrical sample and measuring the resulting angular deformation.

The choice of measurement method depends on factors such as the material type, sample size, and desired accuracy.

Typical values of the torsional modulus for common engineering materials include:

- Steel: 75-80 GPa (10.9-11.6 × 10^6 psi)

- Aluminum alloys: 25-30 GPa (3.6-4.4 × 10^6 psi)

- Copper: 44-47 GPa (6.4-6.8 × 10^6 psi)

- Titanium alloys: 40-45 GPa (5.8-6.5 × 10^6 psi)

Keywords: torsional pendulum tests, resonance methods, angular deformation, newtons per square

Conclusion

The torsional modulus of elasticity is a fundamental mechanical property that describes a material’s resistance to shearing and its response to torsional loads.

Understanding this modulus is essential for engineers and designers when selecting materials and optimizing designs for applications that involve twisting deformation.

By considering the torsional modulus alongside other key mechanical properties, engineers can ensure that their designs meet performance, safety, and reliability requirements.

By selecting materials with appropriate torsional moduli and designing components to withstand torsional stresses, engineers can ensure the safety, reliability, and performance of their products.

Keywords: engineering design, reliability, performance

References

1. Beer, F. P., Johnston, E. R., DeWolf, J. T., & Mazurek, D. F. (2012). Mechanics of Materials (6th ed.). McGraw-Hill.

2. Callister, W. D., & Rethwisch, D. G. (2018). Materials Science and Engineering: An Introduction (10th ed.). Wiley.

3. Budynas, R. G., & Nisbett, J. K. (2015). Shigley’s Mechanical Engineering Design (10th ed.). McGraw-Hill Education.

4. Gere, J. M., & Goodno, B. J. (2013). Mechanics of Materials (8th ed.). Cengage Learning.

5. Ashby, M. F. (2011). Materials Selection in Mechanical Design (4th ed.). Butterworth-Heinemann.

6. ASTM E143-13 (2013). Standard Test Method for Shear Modulus at Room Temperature. ASTM International.

7. ASTM E1876-15 (2015). Standard Test Method for Dynamic Young’s Modulus, Shear Modulus, and Poisson’s Ratio by Impulse Excitation of Vibration. ASTM International.

8. Pakravan, H. R., & Bagheri, R. (2018). Torsional Modulus Measurement Using Ultrasonic Technique. Measurement, 116, 343-350.

9. Roesler, J., Harders, H., & Baeker, M. (2007). Mechanical Behaviour of Engineering Materials: Metals, Ceramics, Polymers, and Composites. Springer Science & Business Media.

10. Zhang, Q., Jiang, S., & Zhao, H. (2017). Effect of Temperature on Mechanical Properties and Deformation Mechanism of Aluminum Alloy 7075. Materials Science and Engineering: A, 678, 325-332.

11. Qiao, P., Yang, M., & Bobaru, F. (2008). Impact Mechanics and High-Energy Absorbing Materials: Review. Journal of Aerospace Engineering, 21(4), 235-248.

12. Mohrbacher, H., & Spöttl, M. (2011). Innovative Lightweight Design with Advanced High-Strength Steels. Science China Technological Sciences, 54(6), 1616-1626.

13. Merati, A. (2005). A Study of Nucleation and Fatigue Behavior of an Aerospace Aluminum Alloy 2024-T3. International Journal of Fatigue, 27(1), 33-44.

14. Zhang, Y., Gao, Y., & Sun, X. (2012). Seismic Performance of Concrete Bridge Piers Reinforced by High-Strength Steel under Torsional Loading. Journal of Bridge Engineering, 17(4), 589-599.