There are two primary grouting techniques used in modern soil engineering applications – traditional cement grouting methods that utilize gravity feeding to permeate soils, and more advanced high-pressure compaction grouting techniques to dynamically densify soils.

Compaction grouting has risen as an innovative solution beyond outdated low-mobility cement grouting for targeted soil stabilization.

However, determining which grout injection technique to use for a particular application can require careful evaluation of the unique advantages of each method.

3 Key Differences Between Cement Grouting vs Compaction Grouting

While both cement grouting and compaction grouting introduce a fluid material underground to stabilize soils, there are some key differences:

- Composition – Cement grouts contain Portland cement, clay and water, while compaction grouts use a mixture of sand, cement and bentonite clay. Compaction grouts therefore contain less clay and more aggregate.

- Injection Method – Cement grout is gravity fed through pipes or hoses under low to moderate pressure. Compaction grouting requires high pressure injection under constant pressure.

- Impact Area – Cement grouting permeates soils further from the injection point. Compaction grouting compacts soils closest to the injection point.

Understanding these core differences informs appropriate applications for each method.

2 Pros and 2 Cons

| Cement Grouting | Compaction Grouting |

|---|---|

| Pros – Very low material costs, Can permeate large areas , Useful precursor to other compaction methods. | Pros – Excellent for stabilizing cohesion less soils, Greater structural strength , Rapid return to service after injection |

| Cons– Not effective for non-cohesive granular soils , More manual work required in drill and inject process, Cured cement is weaker and more permeable. | Cons – Higher material costs , Smaller area of soil impact per injection , Requires special equipment and trained crews. |

Cement grouting remains an economic technique for improving marginal cohesive subsoils prior to conventional compacting.

But the injectable nature of compaction grouts that condense and strengthen targeted soil zones offers more advanced soil stabilization capabilities.

While cement grouting offers extreme cost efficiency, compaction grouting provides targeted soil stabilization uncommon with older cement grouting techniques still in widespread use due to dated specifications.

Cost Comparison of Cement Grouting vs Compaction Grouting

Cement grouting has lower material costs, requiring only Portland cement, clay and water.

However, it relies heavily on labor for drilling injection points and monitoring the flow through soils.

The larger impact area can also require more grout volume to fill voids.

Compaction grouting utilizes more expensive proprietary binders and sands shipped to the site.

But its high pressure injection process requires less manual work to permeate soils.

The smaller impact area also reduces total grout volume required compared to permeating wider areas from injection points.

Overall, compaction grouting costs can exceed cement grouting costs per square foot in many applications. However, project timelines may favor compaction grouting depending on site conditions.

Advantages of Compaction Grouting Over Cement Grouting

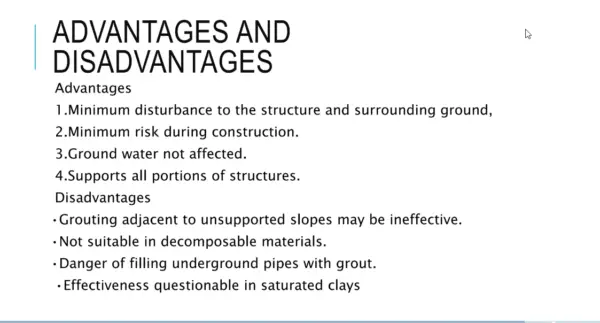

While cement grouting offers very low material costs, compaction grouting provides some key advantages:

- Better for Loose and Granular Soils – The compactivity energy and expandable binders in compaction grouts are superior for densifying non-cohesive sand and gravel soils.

- Cement grouts permeate but do not compact loose soils as effectively.

- Higher Strength – The cured compaction grout mass provides greater structural strength compared to more permeable cement grout formations.

- This provides better uplift resistance and bearing capacity.

- Quick Return to Service – Compaction grouting sites can be returned to active construction and service faster thanks to the method’s limited impact area concentrating the stabilizing effect without loose soils further from injection points.

These advantages make compaction grouting the preferential choice for stabilizing non-cohesive soils and increasing bearing capacity when project timelines are short.

Applications for Cement Grouting vs Compaction Grouting

Cement grouting applications favor permeating large areas where cohesive soils allow slower permeation under gravity injection. Key examples include:

- Pressure grouting below dams, tunnels and retaining walls

- Filling karst cavities and sinkhole voids

- Permeation grouting behind structures on cohesive soils

Compaction grouting applications utilize the technique’s advantages in dense soil stabilization and uplift resistance. Typical applications include:

- Compaction beneath shallow building foundations

- Soil densification prior to slab placement

- Perimeter stabilization and underpinning

- Supporting machinery, bins and tanks sensitive to settlement

Knowing typical applications guides proper selection between the grouting methods for specific project goals and site soil conditions.

When to Use Cement Grouting or Compaction Grouting

Cement grouting should be used when:

- Filling large voids or permeating considerable areas is required

- Injecting under low pressures into cohesive soils like clays

- Stabilizing soils prior to conventional compacting methods

- Material costs are highly sensitive

Compaction grouting should be used when:

- Granular, loose or non-cohesive soils predominate

- Maximum uplift resistance and soil strength is required

- Return to active construction after grouting must be rapid

- Overall project timelines are highly sensitive

On sites with varying soil conditions, both grouting methods may be combined sequentially to utilize the advantages of each technique.

Generally, compaction grouting should be completed before cement grouting to avoid compacted zones restricting flow.

This pressure grouting technique injects proprietary mixes of graded sands, expanding agents and low low-mobility binders that compact and strengthen soils at the injection point.

The capability to consolidate loose sands and increase friction angle in limited treatment zones makes compaction grouting often selected over traditional techniques.

Where advanced soil stabilization is required to improve bearing capacity and resist liquefaction.

Cement Grouting Compared to Compaction Grouting for Soil Stabilization

While cement grouting can permeate and stabilize wider areas prior to construction. Compaction grouting is superior for modern soil stabilization goals. Focused on densifying targeted zones to increase load bearing capacity.

The ability of compaction grouting to consolidate loose sands and non-cohesive soils using expandable binders makes it the preferable technique for soil stabilization on sites with predominantly granular soils.

Using this method to stabilize slab and foundation subsoils prevents future settlement issues.

Materials Used in Cement Grouting vs Materials in Compaction Grouting

The composition of the injected materials differs considerably:

- Cement grouts use Portland cement, clay such as bentonite and mix water. Admixtures may include fly ash or polymers.

- Compaction grouts use proprietary preblended binders containing Portland cement, graded sands for particle size distribution and expansive clays like bentonite. Chemical admixtures provide controlled set times.

The engineered composition of specialized compaction grout mixes enables predictable expansion and strength gain in the unstable conditions deep underground.

Providing reliable solutions for soil stabilization and bearing capacity improvement absent when using basic cement grouts.

FAQ – Cement vs Compaction Grouting

What is the difference between compaction grouting and cement grouting?

Compaction grouting injects low mobility grouts into the soil to displace and compact it.

Cement grouting injects a flowable cement paste/slurry to fill voids or cracks in soils or rock masses.

Compaction grouting strengthens the soil itself, while cement grouting seals openings.

When should I use compaction grouting versus cement grouting?

Compaction grouting would be used to densify and strengthen loose or collapsible native soils, like those beneath foundations or tanks.

Cement grouting would be used when trying to simply fill cracks and voids in rock or soil masses rather than improve the ground itself, such as for dam curtain grouting.

What type of grout mix is used in compaction grouting versus cement grouting?

Compaction grouting uses thick, low slump grouts with less than 1 inch flow that can displace and compact local soils.

Cement grouting uses more fluid cement slurries that can permeate cracks and voids without damaging the surrounding ground.

Mixes differ based on site conditions and project demands.

Conclusion

Specifying compaction grouting over traditionally-utilized cement grouting introduces advanced soil stabilization capabilities and greater structural strength to sites with non-cohesive and granular soils.

Standards are working to catch up with the technical advantages offered by compaction grouting specifications.