Helical piers, also known as helical piles, screw piles, or helical anchors, have become increasingly popular in geotechnical engineering due to their versatility, efficiency, and cost-effectiveness.

Helical piers are an alternative to traditional foundation methods, such as concrete piers or driven piles.

These deep foundation elements consist of a central shaft with one or more helical bearing plates welded to it, resembling a large screw.

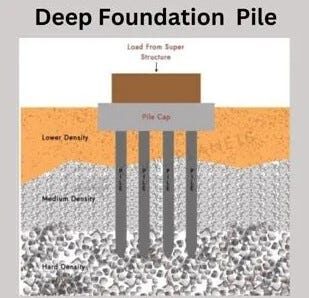

Helical piers are used to transfer loads from structures to stable soil strata or bedrock, making them suitable for a wide range of applications, including new construction, foundation repair, and underpinning.

Keywords: helical piers, helical piles, screw piles, helical anchors, deep foundation, geotechnical engineering

Design and Structure of Helical Pile Foundation

Helical piers consist of:

Shaft:

A central steel shaft, which can be either a solid square bar or a hollow tubular section.

Helical Plates:

One or more helical plates welded to the shaft. These plates resemble large screws and help the pier to anchor into the ground.

Couplings and Extensions:

The piers can be extended by adding additional sections to reach the desired depth.

Advantages of Helical Piers

Offer several advantages over traditional deep foundation systems:

1. **Quick installation:** Helical piers can be installed quickly using hydraulic torque motors, reducing construction time and minimizing site disturbance[1].

2. **Immediate load-bearing capacity:** Once installed, helical piers can immediately support loads, as they do not require curing time like concrete piles[2].

3. **Versatility:** Helical piers can be installed in a variety of soil conditions, including loose sands, soft clays, and even in the presence of groundwater[3].

4. **Minimal environmental impact:** The installation of helical piers produces minimal vibration, noise, and spoil, making them an environmentally friendly choice[4].

Helical Pier Foundations Repair

Helical piers are installed by rotating them into the ground using heavy equipment, such as a hydraulic torque motor.

The process begins with determining the number of piers required based on the weight of the structure and the specific foundation needs.

Helical piers come in different sizes and configurations, with varying shaft diameters and helical plate sizes to accommodate different soil conditions and load requirements.

During the installation process, the helical screw on the pier’s shaft penetrates the soil, creating a stable and secure foundation for the structure.

As the pier is rotated, each additional helical plate increases the load capacity of the pier. The depth to which the piers need to be installed depends on factors such as soil type, water table, and the desired load capacity.

The load capacity of helical piers is determined by several factors, including the diameter of the helical plates, the number of plates, and the soil conditions.

A professional engineer or a licensed contractor specializing in helical pier installation can assess the specific requirements of a project and design a custom solution that meets the necessary load capacity and local building codes.

Patented helical pier systems have undergone extensive testing and have proven their reliability and effectiveness in various construction projects.

From residential homes to commercial buildings and industrial facilities, helical piers have become a go-to foundation solution for their versatility, efficiency, and long-term performance.

Foundation Technologies

One of the primary advantages of helical foundation piers is their versatility. They can be used in a wide range of soil conditions, including loose or unstable soils, where traditional concrete foundations may not be feasible.

Helical piers also have minimal environmental impact, as they require less excavation and can be installed with minimal disturbance to the surrounding landscape.

Another benefit of using helical piers is their ability to prevent foundation settlement. By transferring the load of the structure to more stable soil strata deep below the surface, helical piers provide a reliable and long-lasting foundation solution.

This is particularly important in areas with expansive soils or where soil moisture content fluctuates significantly.

Helical piers also offer a cost-effective alternative to other foundation methods, especially in cases where the local foundation conditions are challenging.

They can be installed quickly, often within a matter of days, reducing construction timelines and labor costs. Additionally, helical piers can be used for both new construction and retrofitting existing structures that may have experienced foundation issues.

Design Considerations

When designing helical piers, geotechnical engineers must consider several factors:

1. **Soil conditions:** A thorough site investigation, including soil borings and laboratory tests, is essential to determine the soil properties and select the appropriate helical pier configuration[5].

2. **Loading conditions:** The anticipated loads on the structure, including dead loads, live loads, and environmental loads (e.g., wind, seismic), must be considered when designing helical piers[6].

3. **Helical pier geometry:** The shaft diameter, helix diameter, helix pitch, and number of helices are critical design parameters that influence the pier’s load-bearing capacity and performance[7].

4. **Corrosion protection:** In aggressive soil environments, such as those with high chloride content or low pH, helical piers may require additional corrosion protection, such as galvanization or sacrificial anodes[8].

Helical Pier Installation Process

The installation of helical piers typically involves the following steps:

1. **Site preparation:** The construction site is cleared, and the locations of the helical piers are marked based on the design plan.

2. **Pier placement:** A hydraulic torque motor is used to rotate the helical pier into the ground. The pier is advanced until it reaches the desired depth or a specified torque value, which indicates that the required load-bearing capacity has been achieved[9].

3. **Load testing:** In some cases, load tests may be conducted to verify the pier’s performance and ensure that it meets the design requirements[10].

4. **Connection to structure:** Once the helical pier is installed, it is connected to the structure using a bracket or other connecting device.

Applications in Geotechnical Engineering

Helical piers have numerous applications in geotechnical engineering:

1. **New construction:** Helical piers can be used as a deep foundation system for new buildings, bridges, and other structures[11].

2. **Foundation repair:** Helical piers are commonly used to stabilize and lift settling or sinking foundations, providing a permanent solution to foundation problems[12].

3. **Underpinning:** When existing structures require additional support due to changes in loading conditions or soil properties, helical piers can be installed to transfer loads to more stable soil layers[13].

4. **Earth retention:** Helical anchors can be used in conjunction with retaining walls, sheet pile walls, and other earth retention systems to provide lateral support[14].

Conclusion

Helical piers have revolutionized the field of geotechnical engineering, offering a fast, efficient, and environmentally friendly solution for deep foundation needs.

By understanding the design considerations, installation process, and various applications of helical piers, geotechnical engineers can effectively utilize this technology to overcome challenges in a wide range of projects.

As the construction industry continues to embrace sustainable and innovative solutions, the use of helical piers is expected to grow, cementing their position as a valuable tool in the geotechnical engineer’s arsenal.

In conclusion, helical piers offer numerous advantages over traditional foundation methods. Their installation process is quick and minimally invasive, they can adapt to various soil conditions, and they provide a stable and long-lasting foundation for structures of all sizes.

As the construction industry continues to embrace innovative solutions, helical piers are poised to play an increasingly important role in meeting the diverse foundation needs of modern construction projects.

## References

1. Perko, H. A. (2009). Helical Piles: A Practical Guide to Design and Installation. John Wiley & Sons.

2. Elsherbiny, Z. H., & El Naggar, M. H. (2013). Axial compressive capacity of helical piles from field tests and numerical study. Canadian Geotechnical Journal, 50(12), 1191-1203.

3. Livneh, B., & El Naggar, M. H. (2008). Axial testing and numerical modeling of square shaft helical piles under compressive and tensile loading. Canadian Geotechnical Journal, 45(8), 1142-1155.

4. Sakr, M. (2009). Performance of helical piles in oil sand. Canadian Geotechnical Journal, 46(9), 1046-1061.

5. Tappenden, K. M., & Sego, D. C. (2007). Predicting the axial capacity of screw piles installed in Canadian soils. Canadian Geotechnical Journal, 44(4), 400-414.

6. Zhang, D. J. Y. (1999). Predicting capacity of helical screw piles in Alberta soils. Master’s thesis, University of Alberta.

7. Ghaly, A., & Hanna, A. (1991). Experimental and theoretical studies on installation torque of screw anchors. Canadian Geotechnical Journal, 28(3), 353-364.

8. Clemence, S. P., Crouch, L. K., & Stephenson, R. W. (1994). Prediction of uplift capacity for helical anchors in sand. Proceedings of the 2nd Geotechnical Engineering Conference, Cairo University, Vol. 1, 332-343.

9. Hoyt, R. M., & Clemence, S. P. (1989). Uplift capacity of helical anchors in soil. Proceedings of the 12th International Conference on Soil Mechanics and Foundation Engineering, Rio de Janeiro, Vol. 2, 1019-1022.

10. Lutenegger, A. J. (2011). Historical development of iron screw-pile foundations: 1836-1900. International Journal for the History of Engineering & Technology, 81(1), 108-128.

11. Perko, H. A. (2000). Energy method for predicting installation torque of helical foundations and anchors. New Technological and Design Developments in Deep Foundations, 342-352.

12. Carville, C., & Walton, J. (1995). Helical piers in expansive soils of Dallas, Texas. Proceedings of the 1st International Conference on Unsaturated Soils, Paris, Vol. 2, 783-788.

13. Vicars, R., & Clemence, S. P. (2000). Performance of helical piles with grouted shafts. New Technological and Design Developments in Deep Foundations, 327-341.

14. Weikart, M., & Clemence, S. P. (1987). Helix anchor foundations: A practical guide to design and installation. Journal of Civil Engineering Practice, 2, 29-37.