Flakiness index is defined as the percentage by weight of the particles in it whose thickness is less than three- fifths (0.6 times) of their mean dimension.

- This test is conducted to determine the thickness of the aggregates.

- This test can help to prevent structural failures and ensure long -term safety and stability of civil engineering projects and building structures.

- The specifications for this test are given in IS : 2386 Part I 1963 Particle size and shape.

Flakiness index test

Procedure

- A metal thickness gauge is the instrument used to conduct this test.

- A sufficient quantity of aggregate is taken such that a minimum 200 pieces of any fraction is tested.

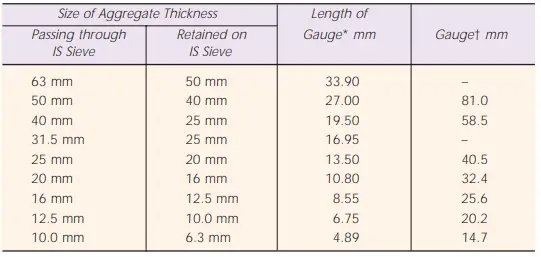

- The sample is sieved through IS sieves as given below.

- The total amount passed in the gauge is measured and weighed.

Dimensions of thickness and length gauge

FLAKINESS INDEX

Elongation Index test

Elongation index is defined as the percentage by weight of the particles in it whose length is greater than 1.8 times of their mean dimension.

- This test is conducted to determine the length of the aggregates.

- When under pressure, materials having a high elongation index are more likely to distort or fracture, endangering the safety of structures.

- Civil engineers may make sure the materials they choose are high quality and appropriate for their intended applications by keeping an eye on the elongation index of aggregate materials.

- The specifications for this test are given in IS : 2386 Part I 1963 Particle size and shape.

Procedure

- A metal length gauge is the instrument used to conduct this test.

- A sufficient quantity of aggregate is taken such that a minimum 200 pieces of any fraction is tested.

- The sample is sieved through IS sieves as given below.

- The total amount retained on the gauge length is weighed.

Elongation Index