In civil engineering, tests on aggregates are crucial to ensure the quality and suitability of materials used in construction projects.

Aggregate is defined as a granular material, typically consisting of sand, gravel, or crushed stone, used in construction as a key ingredient in concrete and bituminous mixes. The properties and quality of the aggregate significantly influence the strength, durability, and performance of the final product.

Aggregates tests help determine the physical, chemical, and mechanical properties of both fine and coarse aggregates, which are essential components of concrete and other building materials.

Aggregate Test in Civil Engineering

In practice, a series of standardized tests are conducted to evaluate the suitability of aggregates for specific applications.

Gradation analysis is performed to ensure proper particle size distribution, with typical specifications requiring aggregates to fall within specified grading limits.

Specific gravity and absorption tests determine mix design parameters, with typical values ranging from 2.4 to 2.9 for specific gravity and 0.5% to 2% for absorption, depending on the aggregate type.

Strength tests, such as the aggregate crushing value (ACV) and aggregate impact value (AIV), assess the aggregate’s ability to withstand stresses.

Typical ACV limits are 30% for concrete wearing surfaces and 45% for other concrete applications, while AIV limits range from 20% to 30% depending on the desired concrete strength.

Abrasion resistance is evaluated using the Los Angeles abrasion test, with typical maximum loss values of 30% to 50% depending on the intended use.

Soundness tests, such as the sodium sulfate test, assess durability against weathering, with maximum allowable losses of 10% to 12%. Alkali-silica reactivity tests identify potentially reactive aggregates that could cause deleterious expansion in concrete.

Practical considerations in aggregate testing involve proper sampling techniques, adherence to standardized testing procedures (e.g., ASTM, BS, or IS standards), and interpretation of results based on project requirements and relevant codes.

Regular quality control testing during construction, such as moisture content (typical range: 3% to 7%) and silt content (typical maximum: 6%) tests, ensures consistent aggregate quality and helps identify any variations that could affect concrete performance.

By diligently conducting and interpreting aggregate tests, civil engineers can make informed decisions in material selection, mix design optimization, and quality assurance, ultimately contributing to the construction of robust and durable structures that meet the desired performance criteria.

Aggregate Test List

Here is a list of aggregate tests according to US (ASTM), European (EN), and Indian (IS) standards, along with other available tests:

1. Gradation (Sieve Analysis):

– ASTM C136

– EN 933-1

– IS 2386 (Part I)

2. Specific Gravity and Absorption:

– ASTM C127 (Coarse Aggregate)

– ASTM C128 (Fine Aggregate)

– EN 1097-6

– IS 2386 (Part III)

3. Aggregate Crushing Value (ACV):

– BS 812-110

– IS 2386 (Part IV)

4. Aggregate Impact Value (AIV):

– BS 812-112

– IS 2386 (Part IV)

5. Los Angeles Abrasion Test:

– ASTM C131 (Small-size coarse aggregate)

– ASTM C535 (Large-size coarse aggregate)

– EN 1097-2

– IS 2386 (Part IV)

6. Flakiness and Elongation Index:

– ASTM D4791

– BS 812-105

– IS 2386 (Part I)

7. Soundness (Sodium Sulfate or Magnesium Sulfate):

– ASTM C88

– EN 1367-2

– IS 2386 (Part V)

8. Alkali-Silica Reactivity (ASR):

– ASTM C1260 (Accelerated Mortar Bar Test)

– ASTM C1293 (Concrete Prism Test)

– EN 12620 (Annex B)

9. Chloride Content:

– ASTM C1152

– EN 1744-1

– IS 2386 (Part VII)

10. Organic Impurities:

– ASTM C40 (Fine Aggregate)

– EN 1744-1

– IS 2386 (Part II)

11. Lightweight Pieces:

– ASTM C123

– EN 1744-1

12. Clay Lumps and Friable Particles:

– ASTM C142

– EN 933-2

– IS 2386 (Part II)

13. Bulk Density and Voids:

– ASTM C29

– EN 1097-3

– IS 2386 (Part III)

14. Moisture Content:

– ASTM C566

– EN 1097-5

– IS 2386 (Part III)

15. Particle Shape (Angularity, Sphericity):

– ASTM D3398

– EN 933-6

16. Aggregate Freezing and Thawing:

– ASTM C666

– EN 1367-1

17. Drying Shrinkage:

– ASTM C157

18. Aggregate Polishing Value:

– BS 812-114

19. Aggregate Abrasion Value:

– BS 812-113

20. Petrographic Examination:

– ASTM C295

– EN 932-3

This list covers the most common and widely used aggregate tests. Some tests may have additional variations or be specific to certain regions or industries.

Suitability of the Aggregate

To ensure the quality of these road aggregates, various tests are conducted on aggregates, beyond the commonly known tests like gradation, specific gravity, and abrasion resistance.

The weight of aggregate plays a crucial role in mix design, while the specific gravity of aggregates affects the volume calculations.

Stripping value of aggregates is determined to evaluate the adhesion between aggregates and bitumen in road construction.

Petrographic analysis examines the mineralogical composition and identifies potentially deleterious substances.

By conducting these tests, the suitability of aggregates for specific applications is determined, ensuring the use of exceptionally strong aggregates that meet the required standards.

Thorough testing guarantees the production of high-quality concrete and bituminous mixes that can withstand the demands of modern infrastructure.

Property of Aggregate

The important ingredients in the preparation of cement concrete are coarse aggregate and fine aggregate. The characteristics of both these aggregates depend on various factors which may be physical, mechanical and thermal properties.

Coarse aggregate tests are essential in determining the suitability of aggregates to be used in the design of concrete and bituminous mixes.

These tests evaluate various properties, such as gradation, where the percentage of aggregates passing through specific sieve sizes is analyzed.

Crushed aggregate tests, like the flakiness and elongation index, assess particle shape and size, which influence workability and strength.

The specific gravity of aggregates normally used in construction ranges from 2.6 to 2.8, with higher values signifying an exceptionally strong aggregate.

Moisture content tests are crucial, as removing moisture from the aggregate ensures accurate batching and mix design.

Abrasion resistance tests, such as the Los Angeles abrasion test, evaluate the durability of aggregates under traffic loading.

Soundness tests determine the aggregate’s resistance to weathering and freeze-thaw cycles. By conducting these tests on the various types of road aggregates provided, engineers can ensure the selection of high-quality materials that meet the required specifications for the intended application.

Aggregates used in concrete or in pavements should meet certain standards and specifications in order to provide necessary quality and performance requirements.

Various tests are conducted on aggregates to determine the physical and mechanical properties of the aggregates, as they play an important role in the selection of materials for construction projects.

In this blog, let’s discuss some tests which determine various properties such as strength, hardness, toughness, durability, workability etc.

Absorption of Aggregates are Important

To mitigate this issue, it is crucial to test porous aggregates for their freeze-thaw resistance using methods like the sodium sulfate soundness test or the ASTM C666 rapid freezing and thawing test.

Aggregates that exhibit excessive loss or damage during these tests should be avoided in concrete exposed to freezing conditions. Alternatively, the use of air-entraining admixtures can improve the freeze-thaw durability of concrete by providing a network of protective air bubbles.

Aggregates used in concrete or in pavements should meet certain standards and specifications in order to provide necessary quality and performance requirements.

Various tests are conducted on aggregates to determine the physical and mechanical properties of the aggregates, as they play an important role in the selection of materials for construction projects.

In this blog, let’s discuss some tests which determine various properties such as strength, hardness, toughness, durability, workability etc.

Test on Coarse Aggregate for Concrete

The flakiness and elongation index tests are important for evaluating the shape of coarse aggregates used in concrete.

Flaky and elongated particles can adversely affect the workability, strength, and durability of concrete.

The flakiness index test measures the percentage of particles with a thickness less than 0.6 times their mean size, while the elongation index test determines the percentage of particles with a length greater than 1.8 times their mean size.

Typical limits for combined flakiness and elongation indices range from 30% to 40%. These tests help ensure that the coarse aggregates used in concrete have a suitable shape for optimal performance and longevity of the structure.

Types of Aggregate Test

Aggregate tests also include evaluations of chemical properties and potential deleterious substances.

The chloride content test determines the presence of chlorides that can cause corrosion of steel reinforcement in concrete.

Typical chloride limits range from 0.01% to 0.06% by mass of aggregate. The organic impurities test identifies organic substances that can interfere with cement hydration and reduce concrete strength.

The lightweight piece test detects low-density particles, such as coal or wood, which can affect concrete density and performance.

The clay lumps and friable particles test measures the presence of weak and compressible particles that can degrade over time. These tests ensure that aggregates are free from harmful substances and meet the required chemical and physical properties for durable concrete production.

Tests for Coarse Aggregate

The bulk density and voids test, as per ASTM C29 or IS 2386 (Part III), is another important evaluation for coarse aggregates used in concrete.

This test determines the bulk density (unit weight) of the aggregate in compacted or loose condition, as well as the percentage of voids between the particles.

Typical bulk density values range from 1,200 to 1,750 kg/m³ (75 to 110 lb/ft³), depending on the aggregate type and gradation.

The void content typically ranges from 30% to 45%. These properties influence the concrete mix design, as they affect the amount of cement paste required to fill the voids and coat the aggregate particles. Lower void content and higher bulk density generally contribute to improved concrete strength and durability.

Tests on aggregates

Several tests are conducted both in coarse and fine aggregates. The following tests which are primarily conducted on coarse aggregates to determine its physical and mechanical properties are given below:

- Sieve Analysis

- Aggregate Crushing test

- Aggregate Impact test

- Aggregate Abrasion test

- Shape test (Flakiness index test and Elongation index test)

- Soundness test

- Specific gravity and water absorption test

Sieve Analysis

Sieve analysis is a method of determining the particle size distribution of coarse aggregates (size more than 4.75 mm) in a sample of aggregate. It is one of the most important tests in civil engineering, as it helps to classify the aggregates and design concrete mixes accordingly.

The test procedure involves passing the aggregate sample through a series of sieves with different openings and measuring the weight retained on each sieve.

The percentage of aggregate retained on each sieve is calculated and plotted on a graph to obtain the gradation curve. The gradation curve shows the relative proportions of different sizes of particles in the aggregate sample.

The sieve analysis test can provide useful information about the properties and performance of coarse aggregates, such as:

- The fineness modulus, which is an index of the coarseness or fineness of the aggregate.

- The uniformity coefficient, which indicates the degree of variation in particle sizes.

- The shape and surface texture, which affect the workability and strength of concrete.

- The specific gravity and bulk density, which influence the weight and volume of concrete.

- The void ratio and porosity, which determine the water absorption and permeability of concrete.

This article will give the complete details of the sieve analysis test.

Aggregate Crushing Value Test

Aggregate crushing test is a standard method of measuring the strength of coarse aggregates used in concrete. The test involves applying a gradually increasing compressive load to a sample of aggregate until it fails or fractures.

The purpose of this test is to assess the quality of aggregate for different types of pavement and construction applications.

Aggregates with low crushing value are more resistant to crushing and therefore more suitable for high-stress conditions such as roads, bridges, and dams.

Aggregates with high crushing value are more prone to crushing and therefore more suitable for low-stress conditions such as sub-bases, fillers, and drainage layers.

This article will give the complete details on aggregate crushing test.

Aggregate Impact Value Test

Aggregate impact value test is a method to measure the resistance of coarse aggregates to sudden impact loading. It is commonly used in civil engineering projects to assess the quality and strength of aggregates for pavement and road construction.

The test involves dropping a steel hammer of a specified weight and height onto a sample of aggregate and measuring the percentage of fines (particles passing through 2.36 mm sieve) produced by the impact.

The lower the aggregate impact value, the higher the resistance of the aggregate to impact loading.

For complete details on aggregate impact value test , refer the above article.

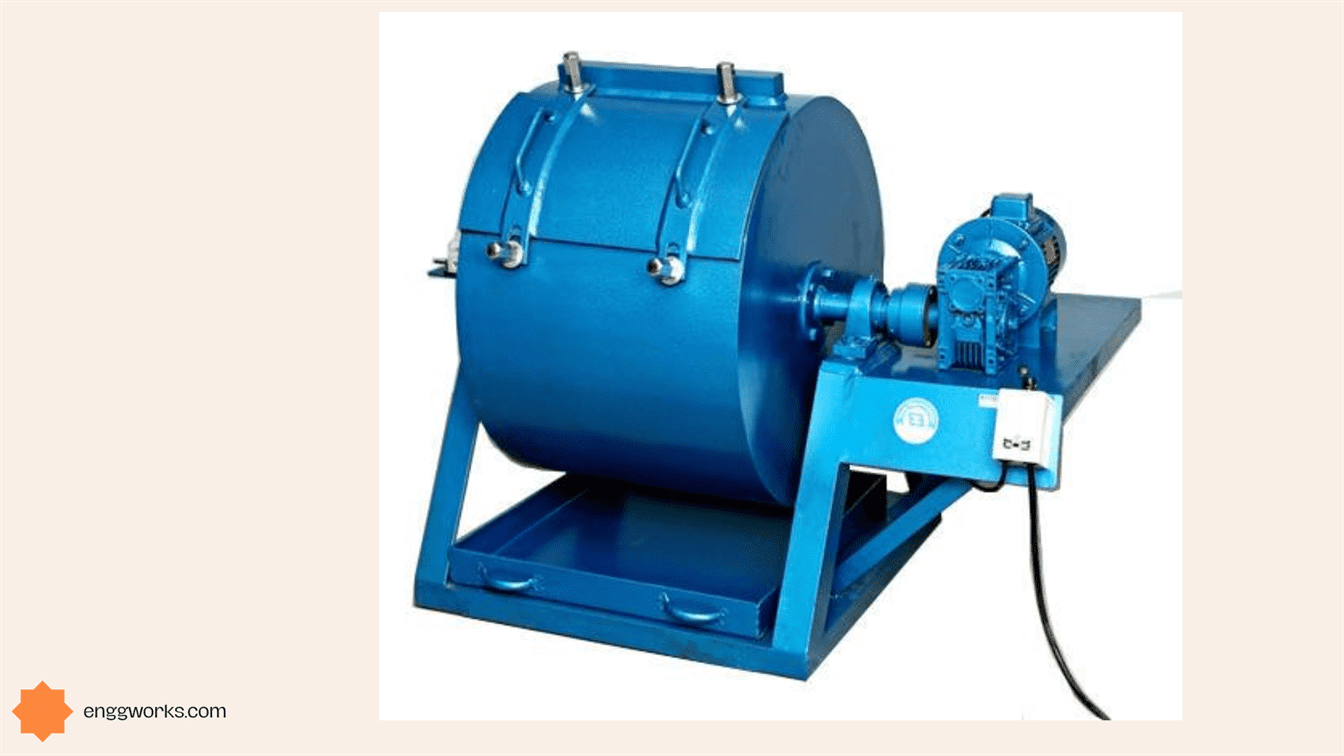

Aggregate Abrasion Test

Aggregate abrasion test is a method of measuring the resistance of coarse aggregates to wear and tear. It is also known as the Los Angeles abrasion test or the L.A. abrasion test.

This test is widely used in civil engineering to assess the quality and durability of aggregates for various construction purposes.

The lower the abrasion value, the higher the quality and durability of the aggregate. The abrasion value depends on several factors, such as the mineralogy, shape, size, gradation and hardness of the aggregate.

The test can also be used to compare different types of aggregates or to evaluate the effect of weathering on aggregates.

For complete details refer the aggregate abrasion test article.

Shape Tests on Aggregates

One of the ways to assess the quality of coarse aggregates is to perform shape tests. Shape tests measure the geometrical properties of the aggregates, such as their size, shape, texture, and angularity.

These properties affect how the aggregates interact with each other and with the cement paste in the concrete mix. For example, aggregates with more angular shapes tend to have higher surface area and require more water and cement to achieve a workable consistency. Aggregates with smoother textures tend to have lower friction and better flowability.

For complete details on shape tests, refer the above article.

Soundness Test

Soundness test on coarse aggregates is a method to determine the durability of aggregates used in concrete and pavement construction. It measures the resistance of aggregates to weathering and chemical attack by exposing them to cycles of wetting and drying or heating and cooling. The test is performed according to the specifications of ASTM C88 or IS 2386 (Part 5).

The purpose of the soundness test is to ensure that the aggregates will not disintegrate or deteriorate under the influence of environmental factors such as moisture, temperature, and chemicals.

The soundness test is important for civil engineering projects because it affects the strength, stability, and durability of concrete and pavement structures. Aggregates that fail the soundness test may cause cracking, spalling, or disintegration of concrete and pavement surfaces.

The soundness value should not exceed the limits specified by the relevant standards or codes for the intended use of the aggregates.

For complete details, know the procedure of soundness test on coarse aggregates.

Specific Gravity and Absorption Test

Specific gravity and absorption test on coarse aggregates is a common laboratory procedure in civil engineering. It is used to measure the physical properties of coarse aggregates, such as their density, porosity and water absorption. These properties affect the strength and durability of concrete and asphalt mixtures.

The test results can be used to evaluate the quality and suitability of coarse aggregates for various construction applications.

For example, aggregates with high specific gravity and low absorption are preferred for concrete production, as they provide higher strength and lower shrinkage. Aggregates with low specific gravity and high absorption are more prone to deterioration and damage due to freezing and thawing cycles.

For complete details on specific gravity and absorption test, read the above article.

Aggregate Crushing Test Importance

The aggregate crushing test, as per IS 2386 (Part IV), assesses the ability of aggregates to resist crushing under gradually applied compressive load.

This test is crucial in concrete technology as it indicates the strength and quality of aggregates, which directly influence the durability and performance of concrete structures.

Aggregates with lower crushing values are preferred for their ability to withstand high stresses without excessive degradation.

Typical values for aggregate crushing value according to IS 383-1970:

| Aggregate Type | Crushing Value (max) |

|---|---|

| Concrete Wearing Surfaces | 30% |

| Concrete Other than Wearing Surfaces | 45% |

Significance of Aggregate Impact Test

The Aggregate Impact Test, as per IS 2386 (Part IV), measures the resistance of aggregates to sudden impact or shock loading.

This test is essential in concrete laboratory testing as it simulates the stresses that aggregates undergo during handling, mixing, and compaction of concrete.

Aggregates with lower impact values are more resistant to breakage and degradation, ensuring better durability and strength of the concrete mix.

The test involves subjecting an aggregate sample to standard impact by dropping a hammer from a fixed height.

- The percentage of fines generated below a specified sieve size is expressed as the Aggregate Impact Value (AIV).

- Lower AIV indicates higher impact resistance.

- Typical AIV limits for different applications are specified in codes and standards.

porous aggregates subjected to freezing

Porous aggregates, such as some lightweight aggregates and certain natural stones, can pose durability challenges when subjected to freezing conditions. The inherent pore structure of these materials allows water to penetrate and reside within the aggregate particles.

When temperatures drop below freezing, this entrapped water expands as it turns to ice, exerting internal pressures that can fracture the aggregate. Repeated freeze-thaw cycles can cause progressive deterioration, leading to cracking, scaling, and reduced strength in concrete made with these aggregates.

Conclusion

By conducting a comprehensive fine aggregate test list and coarse aggregate tests, civil engineers can ensure that the materials used in construction meet the required standards and specifications.

The testing of aggregates for concrete is particularly critical, as the strength and durability of concrete structures depend heavily on the quality of the aggregates used.

In summary, tests in aggregates in civil engineering play a vital role in guaranteeing the safety, reliability, and performance of construction projects.

By carefully evaluating the properties of both fine and coarse aggregates through various test on aggregate, engineers can make informed decisions and select the most suitable materials for their projects.

am interested in learning more about aggregates

M.S.Shetty is a good text book to start with.