Aggregate sieve analysis test is a method of determining the particle size distribution of aggregate samples in concrete technology practice. It is used to classify into different groups based on their grain size and shape.

Sieve analysis of coarse aggregate is a crucial process in determining the particle size distribution and quality of aggregates used in construction projects.

This test involves passing the aggregate sample through a series of sieves with progressively smaller openings to determine the percentage of material retained or passing each sieve.

Understanding how to calculate percent passing in sieve analysis is essential for accurate results.

Aggregate sieve analysis is not limited to coarse aggregates; fine aggregate sieve analysis is equally important. The process for fine aggregates is similar, but with smaller sieve sizes and a larger sample size to ensure accurate representation.

By performing sieve analysis on both coarse and fine aggregates, engineers and contractors can ensure that the materials used in concrete, asphalt, and other construction applications meet the required specifications for particle size distribution, leading to stronger, more durable structures.

Sieve analysis of coarse aggregate can help engineers to select suitable materials for construction projects, such as foundations, pavements, dams, etc.

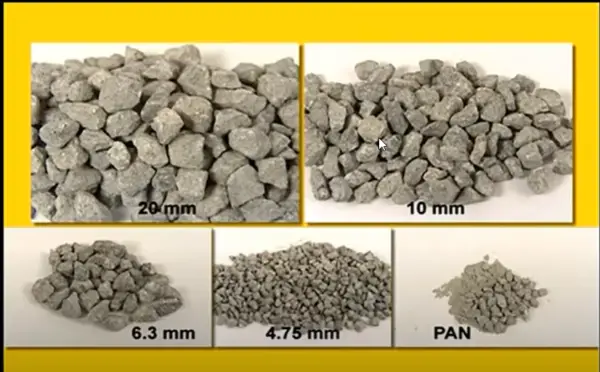

Coarse aggregate is is crushed gravel or stone, uncrushed stone or that is obtained by blending the both. It is technically defined as the one retained on 4.75mm IS sieve.

What is the Purpose of Sieve Analysis

The aggregate contains different sizes in proportions, which is called as graded aggregate. By using single sized aggregate, concrete becomes harsh and is difficult to work with trowels and between cables, sheathing and strands.

The graded aggregate is defined by its nominal size of 80mm, 40mm, 20mm, 16mm, 12.5mm etc to the least size of coarse aggregate.

20mm Aggregate Sieve Analysis Test

- Take a representative sample weighing approximately 1kg from the 20mm aggregate batch.

- Stack a set of IS sieves in descending order – 40mm, 20mm, 16mm, 12.5mm, 10mm, 4.75mm, 2.36mm, 600 microns, 300 microns, and 150 micron.

- Place the sample on the top sieve and shake the column of sieves by hand or machine for 10-15 minutes until no more material passes through them.

- Weigh the material retained on each sieve separately and record the masses.

- Calculate the cumulative percentage retained and percentage passing through each sieve by dividing each retaining mass with total initial sample mass. Plot graph of percentage passing versus sieve size.

How to Calculate Percentage Passing in Sieve Analysis for Coarse Aggregate

- Take a representative sample of coarse aggregate weighing approximately 5kg.

- Sieve the sample through a stack of IS sieves in descending order – 80mm, 63mm, 50mm, 40mm, 25mm, 20mm, 12.5mm, 10mm, 4.75mm.

- Shake the sieves manually or mechanically for 10-15 minutes until no more material passes through them.

- Weigh the aggregate retained on each sieve and record masses as W1, W2 etc.

- Calculate percentage passing through each sieve as (W1+W2+…Wn)/Total initial mass x 100 and plot a graph between percentage passing and sieve sizes with sieve size on X-axis and percentage passing on Y-axis.

Coarse Aggregate Sieve Analysis Table

| IS Sieve Size (mm) | Weight Retained (g) | % Retained | Cumulative % Retained | % Passing |

|---|---|---|---|---|

| 80 | 0 | 0% | 0% | 100% |

| 63 | 145 | 2.9% | 2.9% | 97.1% |

| 50 | 735 | 14.7% | 17.6% | 82.4% |

| 40 | 1250 | 25% | 42.6% | 57.4% |

| 25 | 1030 | 20.6% | 63.2% | 36.8% |

| 20 | 820 | 16.4% | 79.6% | 20.4% |

| 12.5 | 510 | 10.2% | 89.8% | 10.2% |

| 10 | 315 | 6.3% | 96.1% | 3.9% |

| 4.75 | 140 | 2.8% | 98.9% | 1.1% |

| Pan | 50 | 1% | 100% | 0% |

| Total | 4995 | 100% | – |

The first column shows the IS sieve sizes used for coarse aggregate sieving as per standards.

The weight retained on each sieve is recorded and used to calculate the % retained, cumulative % retained, and % passing values which give the size distribution of the aggregate sample.

The total sample weight should reconcile with the cumulative numbers.

Sieve Analysis of Coarse Aggregate

To take a look, a nominal size of 40mm means that most of aggregate passes that particular sieve size. Since aggregates derive their properties from their parent rocks, it is important to know the gradation and fineness modulus. It is to make sure whether they are suitable for workable concrete.

To perform a sieve analysis for coarse aggregate, a representative sample is obtained and dried to remove moisture.

The sample is then weighed and placed on the top sieve of a stack of sieves arranged in descending order of sieve sizes for coarse aggregate. The sieves are agitated, allowing the particles to pass through until they are retained on a sieve with smaller openings.

After the sieving process, the retained material on each sieve is weighed. To determine how to calculate percentage passing in sieve analysis, the cumulative weight of aggregate retained on each sieve is calculated and subtracted from the total sample weight.

The percentage passing each sieve is then calculated by dividing the cumulative weight passing by the total sample weight and multiplying by 100.

Some of the physical and chemical properties like hardness, strength, pore structure, shape, size, texture etc, round, angular etc aggregates are partially depended on the gradation of aggregate.

All the above properties have some type of influence on fresh and hardened concrete. Gradation or sieve analysis test is an indicator for all these properties and we can derive the aggregate use for different construction purposes.

Summary of Sieve Analysis Test

The procedure of sieve analysis test involves passing aggregates through a series of sieves with different openings. The sieves are arranged in descending order of size, from the largest to the smallest.

The aggregate sample is placed on the top sieve and shaken for a specified time. The particles that pass through each sieve are collected and weighed. The weight of each fraction is expressed as a percentage of the total weight of the sample.

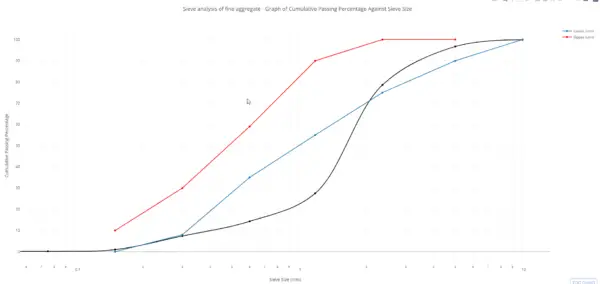

The results of sieve analysis test can be presented in a table or a graph. The table shows the percentage of each fraction by weight and the cumulative percentage passing each sieve.

The graph shows the particle size distribution curve, which plots the cumulative percentage passing each sieve against the logarithm of the sieve opening size. The shape of the curve can indicate the type and characteristics of the coarse aggregate, such as uniformity, gradation, coarseness, etc.

Gradation of Aggregate Test

The main purpose of sieve analysis test is to find the particle size distribution of aggregates. Large samples are collected in the field and brought to the lab for the test. The intention is to see if the aggregates perform the function for the use in concrete.

The distribution of aggregate by particle size in a sample is determined by sieve analysis of coarse aggregate or gradation test.

A curve is drawn to know the cumulative percentage of each fraction. Based on the type of graph, we can determine whether the coarse aggregate sample is well-graded, gap-graded etc. This determines the suitability of the aggregate for that particular field condition.

Coarse Aggregate Sieve Analysis Test

A set of sieves of normalized size are placed one above the other in decreasing order size. It is mechanically shaken for a period of time. After the process is complete, the technician weight the material retained on each sieve.

These are standard set of sieves used according to the IS: 2386 code. The cumulative method of test determines retain fraction amount of coarse aggregate retained on the sieve. As each retain fraction is added, divided by the total mass of the sample taken, and multiplied by 100 to calculate the percentage retained.

Subtract the cumulative percent retained for a given sieve from 100 to get the cumulative percent passing.

- This test is conducted to determine the particle size distribution of the aggregates which is termed as “Grading”.

- This test is conducted both on fine and coarse aggregates.

- The gradation of the aggregates is done during the construction process to ensure consistency in the quality of aggregates.

- The specifications for this test are given in IS : 2386 Part I 1963 Particle size and shape .

Procedure (For coarse aggregate)

- The aggregates used in concrete vary from maximum size of 80 mm to 150 micron. In this procedure let’s discuss the grading of coarse aggregate where the size is from 80 mm to 4.75 mm (size of coarse aggregate).

- Sieving can be done either manually or mechanically.

- In the manual process, a set of sieves are arranged in descending order one below the other and sieves are shaken in all possible directions giving opportunity to all the aggregates to pass through the sieves.

- The procedure is repeated until no particle is passing through the sieve.

- The weight of the sample retained on each sieve is measured.

- The minimum weight of the sample to be taken for this test is specified in the above mentioned code which is given below.

- In this test, fineness modulus is determined which refers to the coarseness or fineness of the material.

- Fineness modulus is calculated by adding the cumulative percentages of aggregates retained on each sieve and dividing this sum by 100.

- An example for calculation of fineness modulus is tabulated below.

Minimum weight of sample for Sieve Analysis (IS : 2386 Part I 1963 Particle size and shape)