Graded coarse aggregate refers to the determination of the particle size distribution.

They are sorted into groups by passing through a series of stacked sieves with progressively smaller mesh openings.

The sieve sizes and percentage of aggregates falling into size fractions are key to the selection and performance of aggregates for different uses.

Coarse aggregates like crushed stone and gravel are essential ingredients in construction materials such as concrete, asphalt mixes, road bases, and structural fills.

Grading Analysis of Coarse Aggregate

The specific sizing and grading of coarse aggregate is an important consideration for optimal performance.

Whether you realize it or not, coarse aggregates are a fundamental ingredient that pave the way for modern life as we know it.

When mixed with other materials like cement and water for concrete or hot mix asphalt production, coarse aggregates provide critical stability, strength, and reinforcement.

However, understanding what defines “coarse” aggregate specifically and how aggregates are evaluated ensures optimal material performance.

Benefits of grading coarse aggregate

A well graded coarse aggregate contains a relatively even distribution of particle sizes, from the largest stones down to the fine-grade gravels.

There should be a substantial representation of all sizes intended for that specific gradation classification.

Well grading of coarse aggregate tend to compact better, reducing voids and increasing density and stability within a concrete or asphalt matrix.

Grading of coarse aggregate Matters

Coarse aggregate resources used in concrete and asphalt contain a composite blend of stones and gravel particles across a range of sizes and proportions adequate enough to deliver specified strength and durability capabilities.

After crushing and processing, aggregate producers use sieve analysis or simple hand shaking methods to determine percentages of different coarse particle sizes yielding from the raw material.

This grading of coarse aggregate assessment ensures outputs match required distribution limits across successive sieve dimensions demanded by state transportation departments or municipal projects.

Well-graded signifies ample intermediate sizes between extremes.

Effects in Mixtures

Combined aggregate gradation is key for performance.

A Well grading of coarse aggregate and fine fractions optimize particle packing density within a mixture, minimizing voids in concrete and asphalt that would reduce strength.

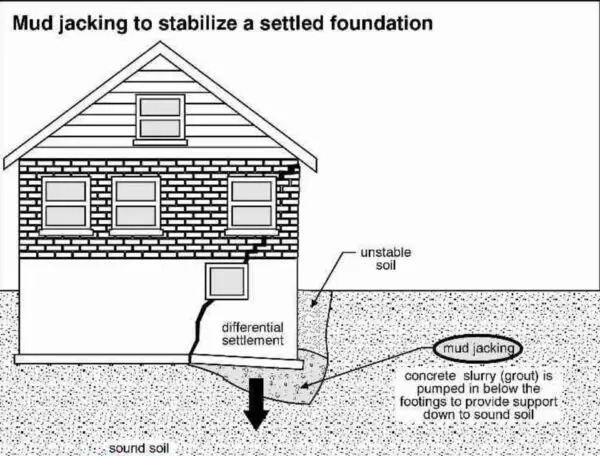

Inadequate gradations can also lead to drainage issues or instability problems in soils.

Testing and analysis ensures suitability for the environment.

Frost susceptibility, for example, may influence choice of gradation.

Angular and Rough Textures

In addition to appropriate grading, individual coarse aggregate particles should exemplify desired qualities ideal for bonding within cement, asphalt binder, and other media.

Sharp, angular aggregate features promote better mechanical locking and resistance to displacement compared to rounded particles.

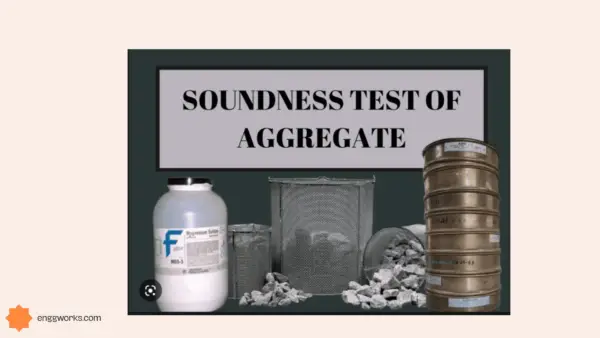

Abrasion-resistant aggregates must also stand up to mixing, handling, spreading, and compaction without significant break down.

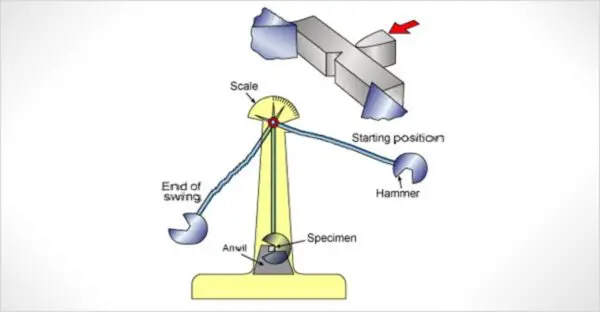

Hardness tests help verify adequate durability.

types of coarse aggregates used in construction

- Crushed Stone

- One of the most widely used coarse aggregates obtained by breaking large stones in a stone crusher.

- Options like granite, limestone, and trap rock bring different levels of hardness and surface texture.

- Angular particles promote good bonding and interlocking.

2. Gravel

- Naturally occurring aggregates produced by weathering and erosion.

- River gravels tend to be more rounded versus angular crushed stone.

- Blast furnace slag, crushed concrete, and expanded clay shale also used.

3. High-Density Aggregates

- These heavyweight options include iron ore, steel furnace slag, nickel slag, barytes, magnetite, etc.

- Used in radiation shielding applications and to provide higher strength concrete.

4. Lightweight Aggregates

- Made from clay, slate, shale, perlite, vermiculite, scoria or pumice.

- Used to reduce dead loads yet maintain good insulation and fire ratings.

5. Recycled Concrete Aggregates

- Crushed concrete reclaimed from demolition projects and recycling centers.

- Can replace virgin aggregates in some applications, promoting sustainability.

The appropriate coarse aggregate type depends on the target use, properties needed, specifications to meet, and options locally available in required gradations and volumes.

Applications

Infrastructure applications dictate the ideal grading of coarse aggregate and individual properties necessary to accomplish the job.

Portland cement concrete demands both coarse and fine aggregates comprising up to 75% of total volume.

Larger maximum size aggregates bring higher strength and stability.

Asphalt roads and parking lots include over 90% well-graded coarse aggregate content, relying on sharp texture and cubical shapes for strength instead of rounder options.

Even soils for structural backfill frequently incorporate blends of coarse gravel and crushed rock, especially for superior compaction around buried structures and drainage capacity.

Conclusion

It’s easy to take ubiquitous coarse aggregates for granted when their critical functions actually impact infrastructure capabilities and life span.

Substandard coarse aggregates degrade more quickly, causing unsafe road hazards for example.

Grading analysis is crucial for securing well-graded coarse aggregates tailored to meet the unique specifications and physical demands of each construction project.

Understanding aggregate sizes simply by names like “Class 5” is not enough.

Comprehensive sieve testing and gradation knowledge ensures contractors get a quality graded product.

This pays dividends through easier placement, better compatibility, and long-lasting aggregate structure.

Specifying appropriate, well-graded coarse aggregates is therefore fundamental for cost-effective, durable infrastructure.