The concrete slump test is a method to determine the workability and consistency of concrete. It is an empirical test that measures the slump of a sample of freshly mixed concrete when it is placed and compacted in a cone shaped mould.

What is Concrete Slump Test?

The slump test is the most commonly used method for measuring the consistency of concrete which directly correlates to its workability. Workability refers to the ease with which concrete flows when it is mixed, placed, compacted and finished.

As per ASTM C143, the slump test involves filling an inverted, truncated metal cone with fresh concrete. The cone is lifted allowing the concrete to ‘slump’. The vertical displacement or slump of the concrete is measured and reported in mm.

Concrete Slump Test Purpose

The main purposes of the slump test include:

- To determine consistency and workability of concrete mix

- To indicate variations in the uniformity/quality of concrete during construction

- To provide correlation between slump and VeBe time or compacting factor for a mix

- To verify if fresh concrete properties comply with specifications

- To monitor deviation in workability during delivery or on-site batching

Thus it acts as a quality control tool and indicates the water content needed for desired workability.

Meaning of Workability

Workability refers to the ease of mixing, placing, compacting and finishing freshly prepared concrete without any segregation or bleeding.

A workable concrete should:

- Allow easy mixing and handling

- Flow readily into moulds and around reinforcement

- Fill formworks without honeycombing or bleeding

- Retain its shape after compaction

Higher workability implies concrete is free-flowing and requires less compacting effort. Workability depends on water content, aggregate properties, use of admixtures etc.

Methods to Calculate Workability

Workability is assessed using tests like:

- Slump test – Measures consistency and water content

- Compacting Factor – Determines degree of compaction

- Flow test – Assesses flowability

- VeBe test – Evaluates stiffness and resistance to handling

Of these, the slump test is the simplest and most common method. The slump value directly indicates the workability.

Concrete Slump Test Procedure

As per ASTM C143, the slump test involves the following steps:

Equipment

- Slump cone – Metal mould in the shape of a frustum of a cone with 8 inch top diameter, 4 inch bottom diameter and 12 inch height.

- Tamping rod – 5/8 inch diameter, 2 feet long steel rod with rounded tip.

- Ruler – To measure slump in mm

- Non-absorbent base plate

Procedure

- Dampen the slump cone and base plate. Place cone centrally on the base.

- Fill the cone 1/3rd height by volume with freshly mixed concrete. Tamp it 25 times with the tamping rod.

- Fill the next 1/3rd and tamp 25 times. Fill remaining 1/3rd and tamp 25 times.

- Level off the concrete at the top.

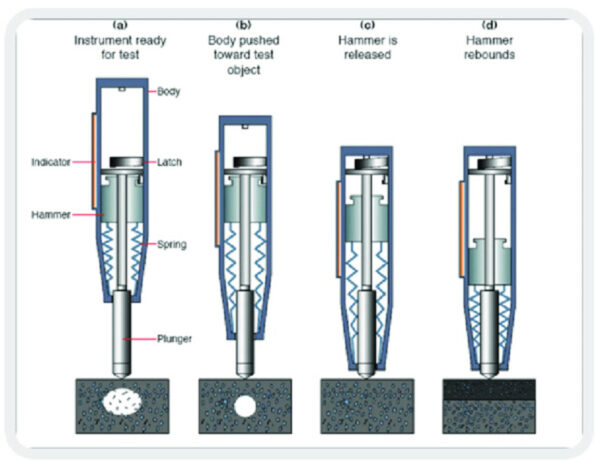

- Slowly lift the cone vertically upwards. Let the concrete slump down.

- Measure the vertical displacement of the center of the slumped concrete. This is the slump in mm.

- Clean equipment thoroughly after the test.

- Report the slump measurement to the nearest 5mm.

Concrete Slump Test Equipment

The equipment needed for slump test comprises:

- Slump cone – Standard metal mould shaped as inverted frustum of cone.

- Base plate – Rigid non-absorbent plate on which slump cone is placed.

- Tamping rod – 16mm dia x 600mm long steel rod with one end rounded.

- Scoop – To place concrete sample into slump cone.

- Ruler – Graduated metal ruler to measure slump in mm.

Equipment should conform to ASTM C143 standards for accurate test results.

Slump Values for Different Grades of Concrete

The slump test measures consistency in terms of slump in mm when concrete collapses after removing cone mould.

Typical slump values for different applications:

- 10-30 mm slump – Vibrated lean concrete

- 25-75 mm slump – Heavily reinforced sections, columns

- 50-100 mm slump – Beams, walls, slabs

- 100-150 mm slump – Lightly reinforced foundation walls and footings

- ≥ 150 mm slump – Plain footings, caissons, subbase concrete

Higher slump indicates higher workability. Slump values vary based on use – stiffer for heavy reinforcement, more workable for mass concrete placement.

Factors Influencing Slump Cone Test

The slump is affected by:

- Water content – Increasing water increases slump.

- Aggregate properties – Smooth, round aggregates give higher slump than angular, rough aggregates.

- Aggregate gradation – Well graded mix has higher slump than poorly graded.

- Admixtures – Plastizers increase slump. Accelerators reduce it.

- Concrete temperature – Warm concrete has higher slump than cold concrete.

- Cement properties – Finer cement increases slump.

- Time – Slump reduces with time after batching due to hydration.

- Compaction – Improper compaction gives false slump reading.

Concrete Slump Test Report

The slump test report should contain:

- Project identification details

- Date and time of sampling

- Location of concrete batch represented by sample

- Slump cone dimensions

- Visual description of sample concrete

- Slump measurements in mm

- Name of tester

- Standard followed for testing

Any deviations from standard test method or abnormal observations should be reported. Graphs comparing different batch slump values can be included.

Concrete Slump Test Acceptance Criteria

Slump test results are evaluated based on:

- Specified slump – The mix design specifies a target slump value or slump range. Test results should conform.

- Consistency – Test results should not vary too much from batch to batch. Variations indicate non-uniform mixing.

- Workability requirements – Slump should match the placement needs – stiffer for heavily reinforced sections, higher slump for plain concrete applications.

Test values conforming to specifications indicate the concrete is of acceptable workability.

Concrete Slump Test Results

Typical slump test results are reported as:

- True slump – concrete subsides evenly in vertical direction after lifting cone.

- Shear slump – concrete shears off vertically on one side causing tilted subsidence.

- Collapse slump – concrete fully collapses into a flattened heap.

A slump of 25 mm means the concrete displaced 25 mm downwards after removing cone. High slump indicates high workability.

The test is repeated on fresh samples from subsequent batches during concrete placement to monitor consistency.

Conclusion

The slump test is an easy, cost-effective field test to determine concrete workability. It measures the consistency of a freshly batched sample when compacted and released from the standard slump cone. Slump value correlates directly to the concrete’s fluidity and water content. It is an essential QA/QC tool widely used in construction for acceptance testing and uniformity monitoring of concrete.