- It is defined as the resistance of coarse aggregate to wear and tear caused by friction.

- This test is conducted to determine the hardness of the aggregate.

- The hardness of the aggregates can be determined by two methods which are Devals abrasion test and Los Angeles abrasion test and the latter one gives the most realistic picture of the abrasion resistance of the aggregate.

- This test helps to evaluate the hardness of the aggregates used in road construction and other civil engineering applications.

- The specifications for this test are given in IS : 2386 Part IV 1963 mechanical properties.

Procedure (Los Angeles Abrasion test)

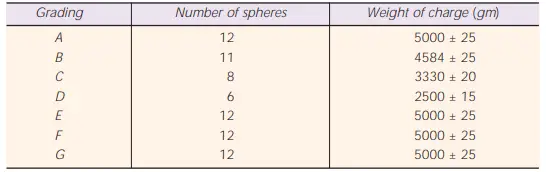

- The abrasive charge consists of cast iron spheres or steel spheres approximately 48 mm in diameter and each weighing between 390 and 445 gm.

- The abrasive charge depending upon the grading is given below

Specified Abrasive Charge

- The test sample consists of clean aggregate which is oven -dried.

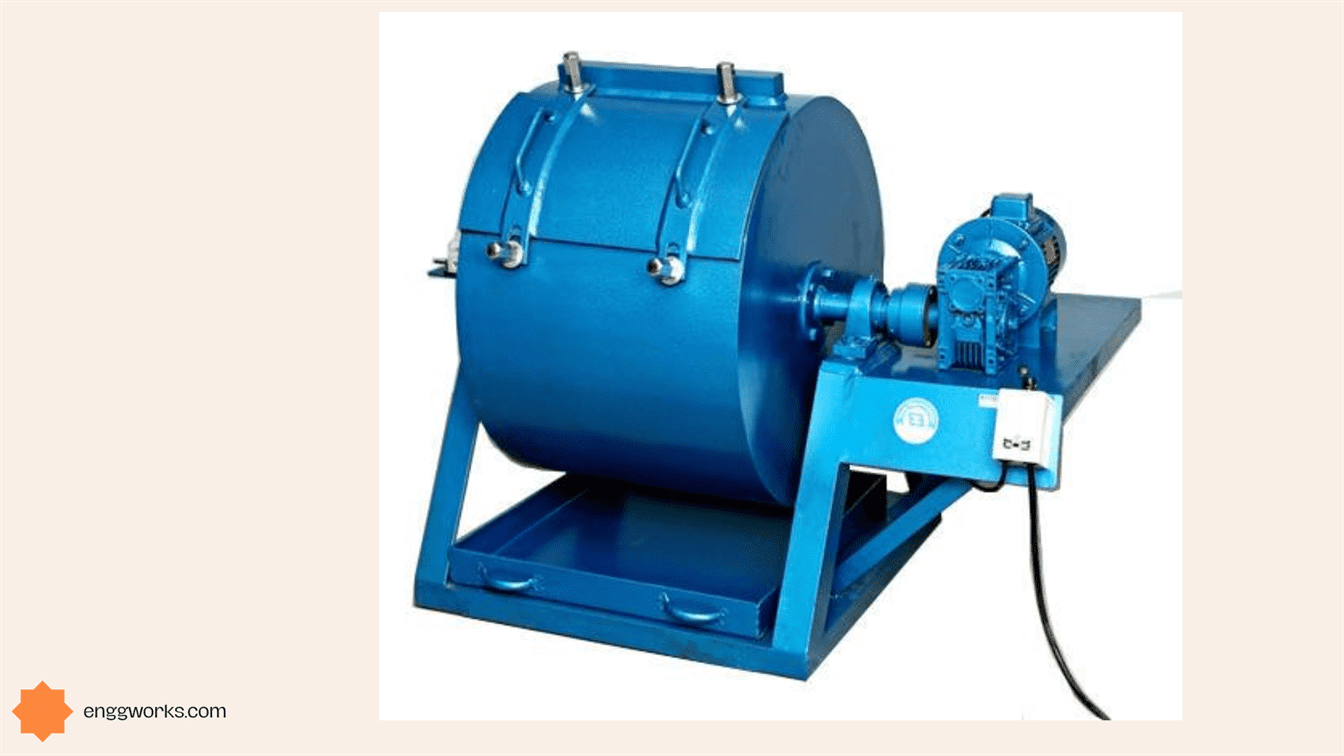

- The test sample and the abrasive charge both are placed in the Los – Angeles abrasion testing machine and the machine is rotated at a speed of 20 to 33 rev/min.

- For gradings A,B,C,D the machine is rotated for 500 revolutions; for gradings E,F,G the machine is rotated for 1000 revolutions.

- After the completion of the above number of revolution, the material is discharged and separation of the sample made on the sieve coarser than 1.7 mm IS sieve.

- Finer portion is then sieved on 1.7 mm sieve; the aggregate coarser than 1.7 mm sieve is washed, oven -dried and weighed accurately.

- The difference between the original weight and the final weight of the test sample is expressed as the percentage of original weight of the test sample.

Note

The percentage of wear should not be more than 16% for concrete aggregates.