Adjustable metal brackets designed to securely join, fasten or provide support connections for horizontal beams in construction projects and structural engineering applications. They utilize sturdy, bolted joints to create reinforced stability points.

Made from galvanized or stainless steel, beam clamps wrap around or attach to beams with indented gripping surfaces and shear resistance strength to hold heavy static and dynamic loading in buildings and infrastructure.

Purpose of Beam Clamps

There are several key advantages that offer over traditional beam connection methods:

Adjustability – They feature movable jaws and eccentrically-bored holes to tighten onto a wide range of beam widths and angles, allowing flexibility if beams shift.

No Drilling/Welding – Quick slide-on installation saves time and labor costs associated with drilling bolts or welding joints.

Resists Vibration – They reinforce structural joints and connections to dampen vibration better than single bolts.

Provides Support – Clamping mechanism evenly grips beams on all sides for enhanced stability and weight-bearing capacity at joints.

Types of Beam Clamps

There are several main types designed for different applications:

Steel Beam Clamps

The most common type, offer high tensile strength and corrosion resistance, featuring:

- Multi-grip styles to fit diverse steel I-beam sizes

- Tempered steel construction tested for fatigue strength

- Galvanized and stainless steel material options

Heavy Duty Beam Clamps

Over-sized versions handle extremely large load capacities and wider flange beams. They prevent crushing failures at high stress connections using:

- Thicker cross-section steel

- Increased grip surface area

- Double shear resistance

Beam Clamps By Project

For construction frame prefabricated modular units with special wood joining clamps.

For DIY projects have compact designs for basic home workshop jobs.

Specials seismic clamps and hangers provide reinforced stability for beam clamps used in earthquake-prone zones.

I-Beam Clamps for Lifting

I-Beam clamps, also known as H-beam clamps, are durable rigging attachments explicitly designed for securely lifting and maneuvering structural beams and columns during construction or fabrication projects.

Made from high strength alloys, these clamps consist of two adjustable jaws that grip the parallel flanges of I-Beams, supported by a base saddle ensuring firm hold without damaging beam integrity.

Threaded rods facilitate adjustable parallel jaw opening from 75mm to 300mm suiting diverse beam sizes. Anti-slip serrated teeth provide 10-15 times stronger grip to safely bear immense loads.

Feature wise, double locking mechanisms on turnbuckles enable tightening from both ends preventing accidental loosening ensuring additional stability of items held during overhead transfers.

While pipe clamps only suit cylindrical sections, universal beam clamps can handle wide flange sizes with powder coating for corrosion resistance. Certified designs adhere to ASME B30 standards for rigging hardware. Shackles allow hoist attachment.

Capable of handling 20 tons in double-pulling capacity, safety latch indicator turns red when maximum capacity is reached to avoid overloading.

They minimize setup time ensuring efficient lifting including options like custom multi clamps for long loads. Compact yet high performing, these versatile fastening devices are integral for structural steel movements on site.

In summary, I-beam clamps designed specifically for heavy lifting enable secure and swift installations.

Applications of beam clamps:

Some of the key applications where they are utilized in construction and engineering projects:

Joining Beams and Girders

- They securely connect horizontal beams to structural girders. Their grip strength resists sheer forces between floors without bolts shearing.

Reinforcing Joints

- Straddling column and beam intersections, beam clamp collars strengthen the integrity of critical joints that experience high fatigue stresses.

Bracing Trusses

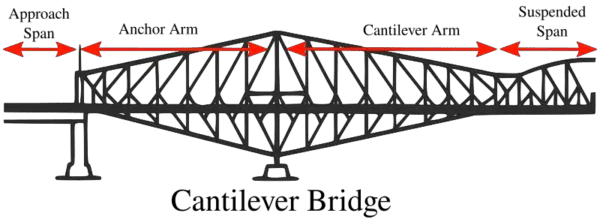

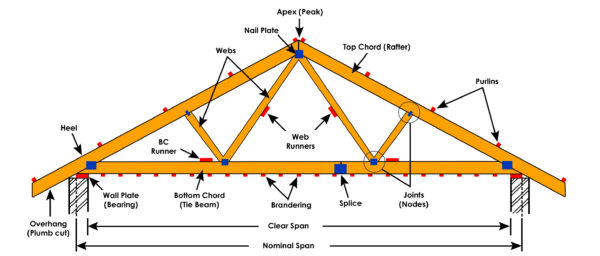

- Adjustable beam clamps are positioned to brace diagonal roof truss members for improved stability and lateral wind resistance.

Temporary Support

- During construction, beam clamps act as temporary connections to support the ends of prefab roof beams until permanent welds or bolts are installed.

Vibration Dampening

- Inherent clamping force helps dissipate vibration energy through joints in equipment, bridges, walkways and other structures.

Skewed Connections

- Eccentric bolt holes allow secured skew angles to accommodate non-perpendicular beam alignments.

In essence, structural and mechanical engineers employ sturdy, adaptable beam clamps in place of custom fabrication to quickly reinforce vulnerable joints and beam connections across many applications.

Conclusion

With quick installation, vibration dampening, and reliable adjustable strength, beam clamps deliver reinforced structural joints for horizontal beams across many civil construction applications.