Cement is an important building material which has broad applications in several fields.

Cement has many uses and applications depending upon its type and composition. Most common uses of cement are listed below which are used in a variety of ways in construction and other industries.

Cement Uses in Construction and Civil Engineering

Cement mortar

Cement mortar is a paste which is used for masonry works,plaster,pointing etc and also building materials like bricks, stones, tiles, and other construction components can be joined with cement mortar. Also, it can be used to patch cracks and faults in surfaces like walls, floors, and ceilings.

Cement concrete

Concrete is used for laying floors,roofs, walls, highways, bridges, dams, A common building material, cement concrete can be used to build foundations, columns, beams, slabs, walls, highways, bridges, dams, and other buildings. Additionally, it can be used to create precast components including pipes, blocks, pavers, and tiles.

Building fireproof or heat proof structures

High temperatures may be withstood by cement, which does not burn or melt quickly. As a result, it may be used to construct objects like chimneys, furnaces, kilns, ovens, fireplaces, and blast furnaces that are required to withstand heat or fire. To improve its thermal insulation and fire protection, cement can also be used with asbestos or other elements that are fireproof.

Stucco and plaster

Plaster and stucco, which are frequently used for interior and exterior walls and ceilings, are made with cement.

Flooring

For both indoor and outdoor environments, cement may be utilized to build resilient flooring that is strong and durable.

Cement board

It is made up of cement and reinforcing fibers that are used as a material for tiles or other finishes. It is used in fireproofing, floor underlayment, tile backing, walls or floors in wet areas such as bathrooms and kitchens etc.

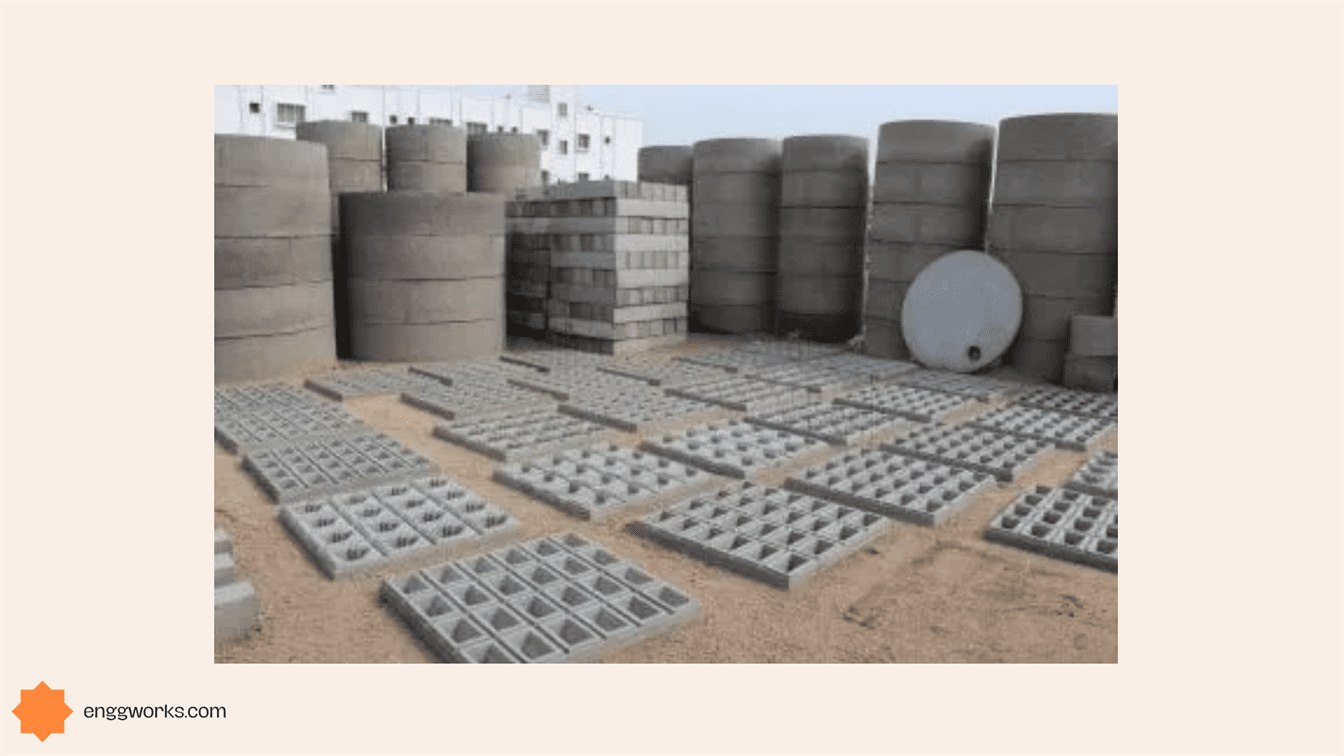

Precast concrete products

Precast concrete items, such as pipes, panels, and blocks, are made using cement and subsequently employed in building projects.

Stabilization of soil

Soil may be strengthened and made more stable with cement, making it suitable for construction.

Grouting

The gaps and joints between tiles and other materials are filled with cement-based grout to provide a solid and robust surface.

Soil erosion control

Additionally, cement may be used to build levees, retaining walls, embankments, dikes, and other structures that stop floods and soil erosion.

Decorative and artistic products

Sculptures, statues, fountains, planters, benches, tables, lamps, and decorations may all be made out of cement by moulding it into different shapes and forms.

Bridges and dams

Due to its strength and durability, cement is widely employed in the construction of bridges and dams.

Paving

Paving blocks, which are frequently used for sidewalks, driveways, and other outdoor places, are made using cement.

Marine Structures

Due to its resilience to saltwater and other extreme environmental conditions, cement is frequently used in the building of seawalls, jetties, and other maritime constructions.

Underground construction

Cement is frequently used to provide stability and support in subterranean building projects like tunnels and underground mines.

Water treatment

Concrete tanks, pipelines, and other structures that can survive the abrasive conditions of water treatment are made using cement in water treatment plants.

Nuclear power plants

The use of cement in nuclear power plant construction ensures the safety of the facility by providing a solid and sturdy foundation for large machinery.

In conclusion, cement has a wide range of applications and is crucial to several different sectors. Providing stability and resilience in a variety of projects and applications, its strength, durability, and adaptability have made it an essential material in the modern world.