When constructing buildings, roads, tunnels and other infrastructure, engineers often encounter unstable soils that require stabilization.

Two of the most effective methods for stabilizing and strengthening the surrounding soil are compaction grouting and jet grouting.

Both techniques involve injecting materials into the ground to strengthen and stabilize it, but there are some key differences. But what exactly sets them apart and when should each method be used?

But when should civil engineers use one ground improvement method over the other? This in-depth guide examines how each grouting technique works, their applications, advantages and downsides.

Compaction Grouting vs Jet Grouting – Key Differences

| Description | Compaction Grouting | Jet Grouting |

|---|---|---|

| Working Principle | Injects viscous grouts that displace and compact soils | Uses high-pressure jets and air to erode, mix and inject soils |

| Strengths Achieved | 50-500psi typically | 100-1500psi |

| Treated Soils | Effective for sands and gravels | Broader range including silts and clays |

| Scale | Smaller, localized treatment | Large-scale improvement possible |

| Cost | $15-30 per sf typically | $30-60 per sf |

Both methods have upsides and downsides that depend on site-specific goals. Consult a professional to determine which best suits your project requirements.

Compaction grouting works by injecting a very thick, low mobility grout into the soil which displaces and compacts the surrounding ground as it spreads, closing voids and binding soils together.

It’s best suited to granular soils like sands and gravels. The key benefit of compaction grouting is that it delivers pinpoint treatment to zones that need improvement the most.

Jet grouting takes a different approach – it uses high velocity fluids to erode and mix the soil while also injecting a grout.

This creates strong soil-cement columns that increase load bearing capacity.

Jet grouting can treat a wider variety of soils including silts and clays. It can also construct larger underground structures like walls and foundations.

For more in-depth coverage you can read our guide on pressure grouting.

Pros and Cons

Both jet grouting and compaction grouting have pros and cons in terms of the soils they can treat, cost, strengths achieved, and more.

Compaction grouting tends to be faster and more economical for small scale improvement whereas jet grouting offers greater versatility for large scale projects.

Proper site characterization and investigation is crucial to determine which solution makes the most sense.

By the end, you should have a good understanding of the pros and cons of compaction grouting and jet grouting and when one may be preferred over the other for ground improvement projects.

What is Compaction Grouting?

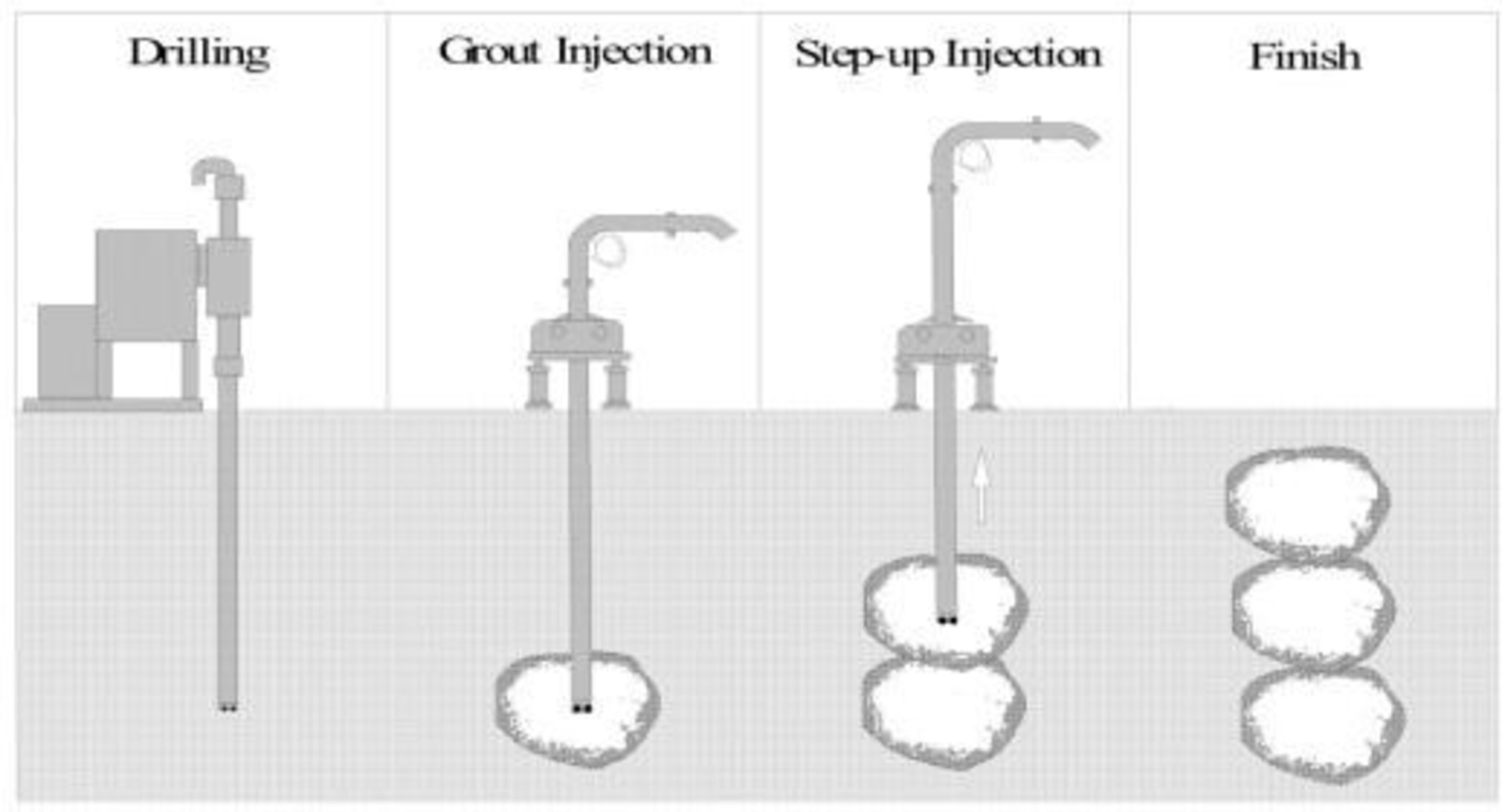

Compaction grouting involves injecting a thick, viscous grout into the subsurface to densify loose and collapsible soils.

The low mobility grouting permeates voids and pore spaces, displacing and compacting the ground to increase load-bearing capacity.

This grouting process generally uses cementitious or chemical grouts containing sand, cement, clay and other additives that resist flow.

Once injected under pressure, the stiff grout expands outwards, but only short distances before hardening, limiting its spread.

What Does Jet Grouting Entail?

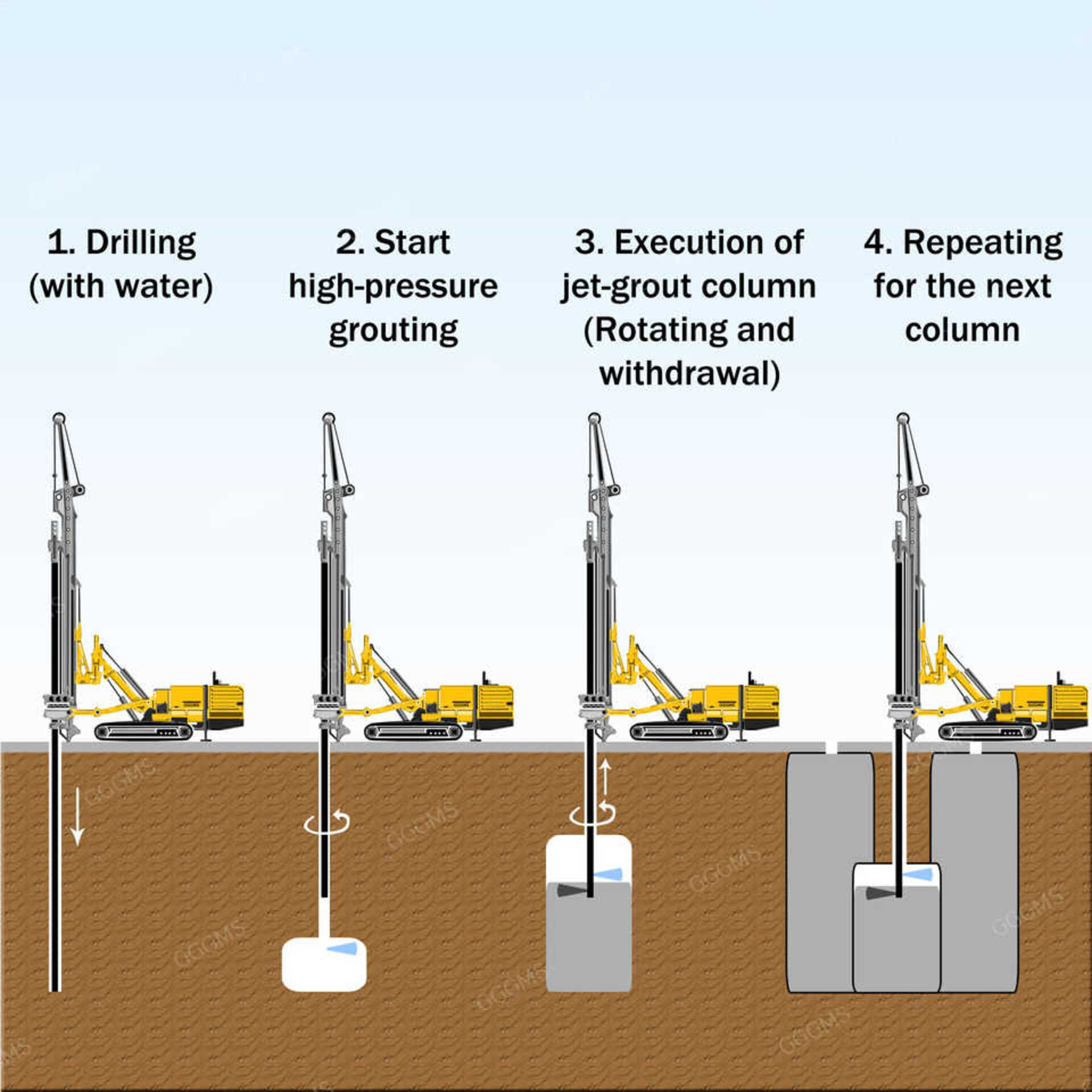

Unlike compaction grouting which relies on displacement from a viscous grout, jet grouting utilizes high velocity fluids to erode, mix and inject soils in-situ.

There are several jet grouting techniques, but they typically involve pumping water or air at pressures exceeding 6000 PSI together with a grout slurry.

The high pressure fluids break down the soil structure while the grout stabilizes the disturbed ground by filling voids and binding soil particles.

This forms continuous columns or panels of soil-cement with improved load-bearing strength. Jet grouting can mix grouts through the full depth of treatment or in distinct lift stages.

Key Applications of Compaction Grouting

Compaction grouting works well in:

- Granular soils like sands and gravels

- Loose fill beneath structures

- Voids underneath slabs or foundations

- Pre-treating collapse-prone ground before construction

- Post-treating subsidence under existing buildings

It localized treatment that’s ideal for small, difficult to access sites.

Compaction grouting is also cost-effective for improving loose sands prone to liquefaction from earthquakes or oscillating loads.

When to Use Jet Grouting

Jet grouting has broader site applicability, enabling ground improvement even in fine-grained soils and bedrock. Some key applications include:

- Underpinning structures and utilities threatened by cavity formation

- Forming subsurface walls and geometries like tunnels

- Waterproofing below-grade spaces against groundwater

- Stabilizing slopes prone to landslides

- Enhancing soils prior to excavations

The ability to construct larger load-bearing elements also suits jet grouting to major infrastructure projects.

Designing an Effective Compaction Grouting Program

Several steps go into designing an effective compaction grouting scheme:

- Set clear improvement objectives like minimum soil strength

- Conduct subsurface investigations with borings and tests

- Choose suitable grout rheology (flow properties)

- Determine grid spacing, injection order and parameters like rate

- Continually assess ground response to optimize work

The chief design goal is displacing and densifying soils without causing surface heave. Careful monitoring of grout volumes, pressure and ground movement provides quality control. Post-treatment testing verifies design objectives were met.

Executing Quality Jet Grouting

The keys to proper jet grouting include:

- Detailed assessment of subsurface layers and properties

- Selecting equipment, nozzles and operating parameters matched to site conditions

- Controlling injection rates and speeds to achieve design geometries

- Monitoring jetting parameters like pressure and flow in real-time

- Taking samples to assess in-situ mixing quality

- Testing integrity with coring and lab analysis

With jet grouting, the soils heavily influence results. Weaker soils allow greater erodibility and mixing while dense layers can limit treatment. Real-time monitoring coupled with experience optimizes the soil-cement formation.

Conclusion

In summary, compaction grouting and jet grouting offer versatile solutions for stabilizing shifting soils and restoring lost ground capabilities – underpinning, void filling, liquefaction mitigation and more.

While their working mechanisms differ, combining targeted compaction grouting with jet grouting’s extensive treatment can produce optimum improvements.

With care taken in design and execution, engineers can overcome unstable ground using these invaluable grouting processes.