Concrete jacking, also known as slab jacking or mud-jacking, is a process of lifting settled concrete slabs back to their desired elevation.

It is an economical method of fixing uneven concrete floors and repairing cracked and uneven concrete without needing to replace the entire slab.

The process involves drilling holes into the sunken slab and pumping a grout mixture underneath to slowly raise it back into place.

Purpose of Concrete Jacking

Concrete inevitably settles and shifts over time due to factors like erosion, ground movement, deterioration of the subsurface, and excessive loads placed on the slab. Concrete jacking is used for:

- Raising sunken concrete driveway, walkways, or patios that have settled over time

- Leveling concrete patios or garage and basement floors that have settled unevenly

- Fixing tilted garage concrete floors that are unsafe or uneven

- Repairing uneven concrete porches and steps

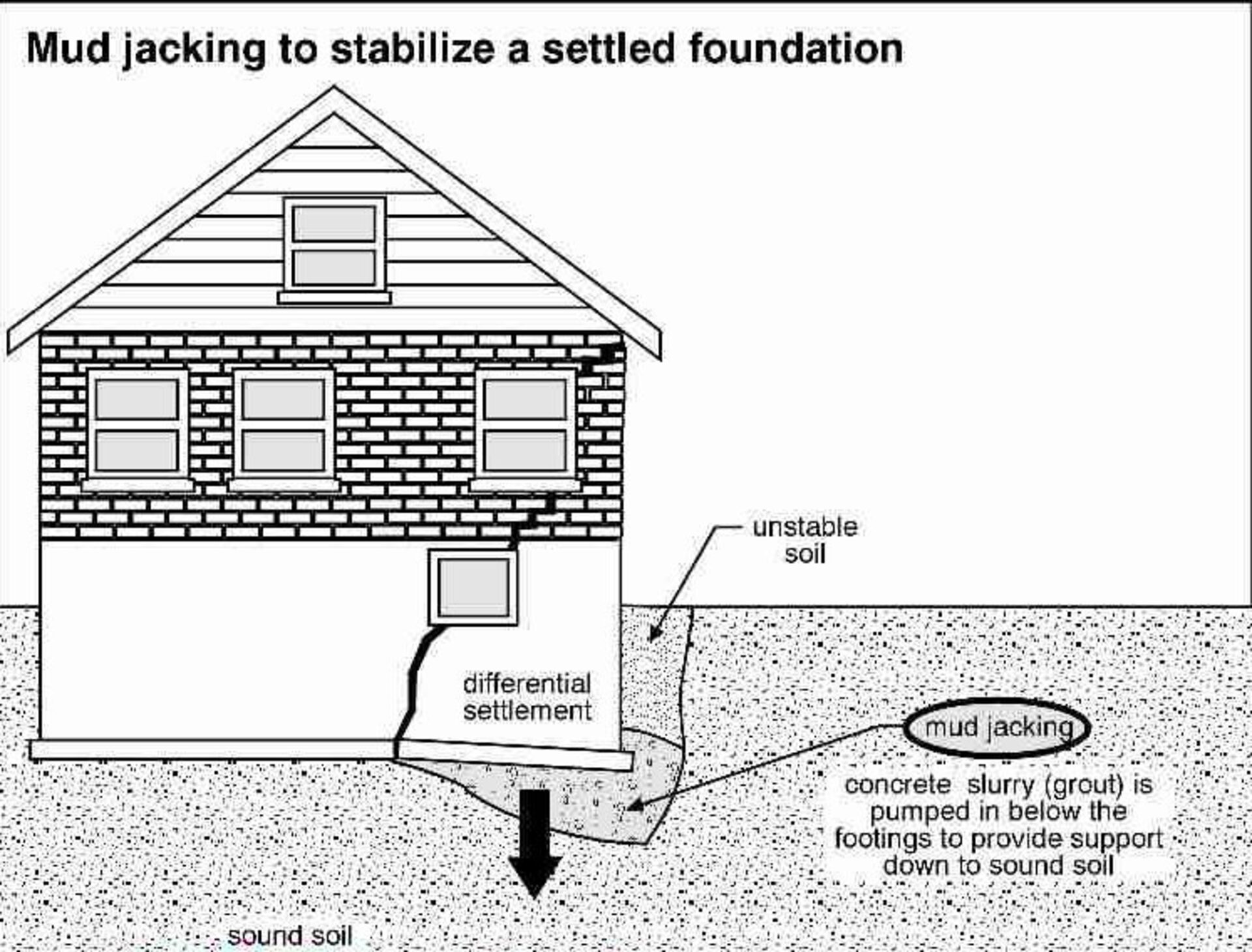

- Lifting and stabilizing concrete slab foundations that have sunk or moved out of place

Rather than demolishing and replacing expensive concrete, jacking lifts, relevels, and stabilizes problem slabs.

Methods Used for Concrete Jacking

There are two primary methods contractors use to lift and stabilize settled concrete slabs:

Slab Jacking

Slab jacking, sometimes called slab leveling, is the most common approach and involves:

- Drilling a series of holes into the sunken concrete slab

- Pumping a special grout mixture underneath the slab through the holes

- The grout expands and slowly lifts the entire slab back into place

Grout Materials

Popular grouting options include:

- Polyurethane foam

- Polyurethane resin

- Limestone-based hydraulic cements

These all expand as they cure, allowing them to provide lifting force. Polyurethane grouts provide the most lift.

Process

During a typical slab jacking process:

- Holes are core drilled into the slab

- Perimeter holes may have rebar installed for extra support

- Grout is pumped below the slab through the holes

- The slab begins slowly lifting as the material expands

- Additional grout is added to achieve the desired elevation

- Once cured, the holes are patched flush

Slab jacking levels floors accurately without needing to demolish or remove the slab.

Mud-jacking

Mud-jacking, sometimes called pump and lift, differs in that it uses concrete rather than polyurethane-based grouts. The process involves:

- Drilling holes into depressions and along slab edges

- Pumping a pressurized concrete slurry below the slab

- The high psi pressure physically lifts the slab

- The slurry fills voids and hardens into a new base layer

Though more equipment intensive, mud-jacking can lift badly settled slabs higher in one session. Materials like concrete and limestone cement permanently stabilize issues.

Both slab jacking and mud-jacking offer cost-effective solutions for lifting and leveling settled exterior flatwork and structural interior slab problems.

Advantages of Concrete Jacking

Concrete jacking offers many benefits over slab demolition and replacement:

- Much more affordable – reduces repair costs by 50% or more

- Less invasive to yard landscaping and structures

- Much less labor intensive – slabs lifted in hours/days rather than weeks

- Eliminates demolition waste – eco-friendly process

- Restores structural stability and correct drainage slopes

- Stops continued settlement problems

- Long-lasting repairs that can exceed 20 years

Applications of Concrete Jacking

Concrete jacking can effectively lift and stabilize settled or uneven concrete slabs in nearly any location:

Exterior Concrete

Common exterior projects include:

- Sidewalks – Public sidewalks often settle unevenly over time, causing trip hazards. Jacking can quickly relevel large sections.

- Driveways – Settling driveways should be lifted to prevent further cracking and patching.

- Patios – Jacking relevels shifted patios and walkways without removing decking or railings.

- Pool Decks & Aprons – Jacking gently lifts pool decks without disturbing the structure.

- Porch Slabs – Older front or backyard porches often settle and crack over time.

Interior Concrete

Interior applications include:

- Basement Floors – Interior floors crack and settle due to soil movement and hydrostatic pressure issues. Stabilizing these slabs with steel rebar and jacking prevents continued problems.

- Garage Floors – Similar to basement slabs, garage floors shift and crack. Mud-jacking lifts, fills, and strengthens these slabs.

- Warehouse & Workshop Floors – Jacking can lift and reinforce the concrete floors in commercial spaces prone to fork truck and heavy vehicle traffic.

Foundation Slabs

- Home Foundations – Improper curing or soil issues causes foundations to shift and crack over time. Injection of stabilizing grout restores structural integrity.

- Commercial Building Slabs – Similar building slab settlement causes doors to not close properly or windows to crack from shift. Jacking lifts and levels the slab.

In many cases, jacking repairs settled exterior and interior concrete slabs can last over 20 years when proper stabilization techniques are also used.

Both exterior and interior concrete slabs can be effectively raised and stabilized with jacking techniques.

Materials Used for Concrete Jacking

Polyurethane grouts or concrete grout slurries are most commonly used:

- Polyurethane foams and grouts expand underneath to lift slabs

- Portland cement-based grouts/slurries pump into voids. As they cure and harden they form a new solid base

- Materials used must be able to flow easily, expand with force, fill voids, and cure into a sound subsurface.

Conclusion

Concrete inevitably settles over time, leading to cracked, uneven slabs. Rather than expensive replacements, concrete jacking techniques provide economical repair by lifting and stabilizing settled slabs.

Holes are drilled into the depressed slabs, then grouts and slurries are pumped below the concrete to raise it back into correct position.

Jacking saves over 50% compared to traditional slab replacement.