Aggregate quality plays a crucial role in determining the strength, durability, and overall performance of concrete structures.

The properties of aggregates, such as particle size distribution, shape, surface texture, and mineralogy, significantly influence the mechanical and physical characteristics of concrete.

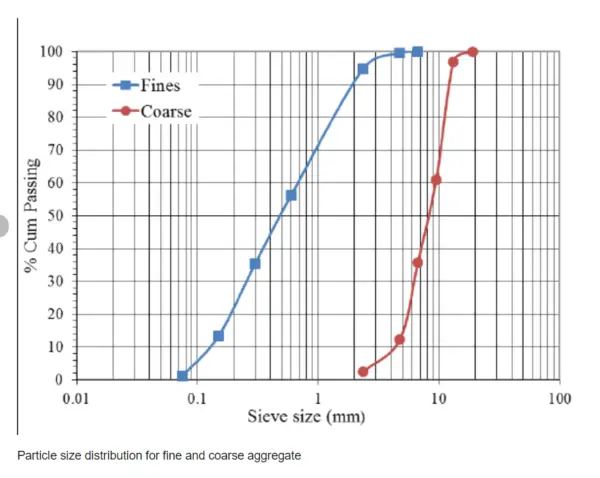

For instance, well-graded aggregates with a continuous particle size distribution, ranging from 75 μm to 4.75 mm for fine aggregates and 4.75 mm to 63 mm for coarse aggregates, contribute to improved workability and reduced void content in concrete.

Studies have shown that the use of aggregates with a rougher surface texture can enhance the bond strength between the cement paste and aggregates by up to 30%, leading to improved compressive strength.

Moreover, the presence of deleterious substances, such as clay lumps, organic impurities, and reactive silica, should be limited to less than 1% by mass of aggregates to prevent adverse effects on concrete durability.

The crushing strength of aggregates, typically ranging from 100 to 300 MPa, directly influences the compressive strength of concrete.

Therefore, stringent quality control measures, including sieve analysis, specific gravity, water absorption, and soundness tests, are essential to ensure the selection of high-quality aggregates for the production of durable and sustainable concrete structures.

Keywords: aggregate quality, particle size distribution, surface texture, bond strength, deleterious substances, crushing strength, quality control

How to Check Quality of Aggregate on Site?

- Visual inspection: Check for any visible impurities, such as clay lumps, organic matter, or foreign materials.

- Gradation: Perform a sieve analysis to ensure the aggregate meets the required particle size distribution.

- Shape and surface texture: Visually assess the shape and surface texture of the aggregates for any irregularities or excessive flakiness.

- Moisture content: Determine the moisture content of the aggregates using the oven-drying method or moisture meter.

- Specific gravity: Measure the specific gravity of the aggregates using a pycnometer or other suitable methods.

- Water absorption: Conduct a water absorption test to evaluate the porosity and water absorption capacity of the aggregates.

- Crushing strength: Perform a crushing strength test using a compression testing machine to assess the aggregate’s resistance to crushing.

- Soundness: Carry out a soundness test using sodium sulfate or magnesium sulfate to determine the aggregate’s resistance to weathering.

- Organic impurities: Test for the presence of organic impurities using the colorimetric method or other suitable techniques.

- Alkali-aggregate reactivity: Check for potential alkali-aggregate reactivity using standard test methods, such as ASTM C1260 or ASTM C1293.

Quality of Coarse Aggregate

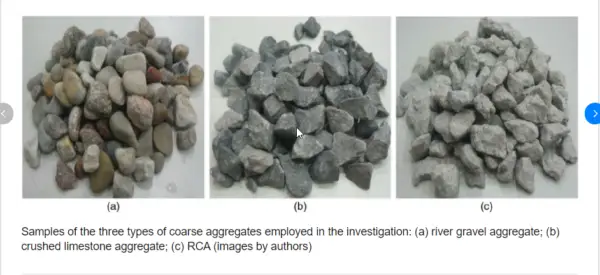

Coarse aggregate quality is a critical factor in the production of high-performance concrete. The properties of coarse aggregates, typically ranging from 4.75 mm to 63 mm in size (IS 383:2016), significantly influence the strength, durability, and structural integrity of concrete.

Coarse aggregates should be clean, hard, and free from any deleterious substances, such as clay lumps (not exceeding 1% by mass), organic impurities (not darker than the standard reference color), or reactive minerals (IS 2386 Part 2).

The particle shape and surface texture of coarse aggregates play a vital role in the workability and bond strength of concrete.

Angular and rough-textured aggregates provide better interlocking and bond with the cement paste, resulting in improved mechanical properties. Studies have shown that the use of angular coarse aggregates can increase the compressive strength of concrete by 10-20% compared to rounded aggregates (Neville, 2011).

The gradation of coarse aggregates should be well-distributed to minimize voids and ensure optimal packing density.

A well-graded coarse aggregate with a fineness modulus between 5.5 and 8.0 (IS 383:2016) contributes to the production of dense and homogeneous concrete. The crushing strength of coarse aggregates, typically ranging from 100 to 300 MPa (Mehta & Monteiro, 2014), directly influences the compressive strength of concrete.

Additionally, the soundness and durability of coarse aggregates are crucial for the long-term performance of concrete structures exposed to various environmental conditions. The aggregate impact value should not exceed 45% for concrete used in pavements and 30% for other structures (IS 2386 Part 4).

Regular quality control tests, such as sieve analysis (IS 2386 Part 1), specific gravity (IS 2386 Part 3), water absorption (not exceeding 2% by mass, IS 2386 Part 3), and abrasion resistance (maximum loss of 50% by mass, IS 2386 Part 4), are essential to ensure the selection of high-quality coarse aggregates for the production of durable and sustainable concrete structures.

References:

- IS 383:2016. Coarse and Fine Aggregate for Concrete – Specification. Bureau of Indian Standards.

- IS 2386 (Part 1 to 4):1963. Methods of Test for Aggregates for Concrete. Bureau of Indian Standards.

- Mehta, P. K., & Monteiro, P. J. (2014). Concrete: Microstructure, Properties, and Materials (4th ed.). McGraw-Hill Education.

- Neville, A. M. (2011). Properties of Concrete (5th ed.). Pearson Education Limited.

Quality of Aggregates in Concrete

Aggregate quality significantly impacts concrete performance. Ideal aggregates are clean, hard, and free from impurities. Well-graded aggregates (4.75-63 mm for coarse, 75 μm-4.75 mm for fine) ensure optimal packing and strength.

Angular, rough-textured aggregates enhance bonding with cement paste. Deleterious substances should be limited to 1% by mass.

Crushing strength (100-300 MPa) influences concrete compressive strength. Water absorption (<2%) and soundness are crucial for durability. Sieve analysis, specific gravity, and abrasion resistance tests ensure quality.

Adherence to standards (e.g., IS 383, IS 2386) is essential for producing high-performance, durable concrete structures.

How Important is High Absorption Quality of Aggregates?

The water absorption of aggregates is a critical quality parameter that significantly influences the performance and durability of concrete, as recognized by the Indian Standard (IS) codes.

According to IS 2386 (Part 3):1963, the water absorption of coarse aggregates should not exceed 2% by mass, while for fine aggregates, it should be limited to 1% by mass. High water absorption in aggregates can lead to several issues in concrete production and performance.

Firstly, aggregates with high water absorption tend to absorb more water from the concrete mix, leading to a reduction in the effective water-cement ratio.

This can result in decreased workability and increased difficulty in placing and compacting the concrete. Consequently, the concrete may exhibit reduced strength and durability properties.

Moreover, aggregates with high water absorption are more susceptible to volume changes due to moisture fluctuations.

When exposed to varying environmental conditions, such aggregates can undergo significant expansion and contraction, leading to the development of internal stresses within the concrete.

This can cause cracking, spalling, and other forms of deterioration, compromising the structural integrity and longevity of the concrete.

To mitigate these issues, IS codes emphasize the importance of using aggregates with low water absorption.

Regular testing of aggregates for water absorption, as per IS 2386 (Part 3):1963, is crucial for quality control in concrete production.

By adhering to the specified limits and selecting aggregates with low water absorption, engineers and contractors can ensure the production of high-quality, durable concrete that meets the desired performance criteria and withstands the test of time.