Steel beams are horizontal or diagonal structural members that are designed to carry transverse loading across a span onto vertical columns at each end.

They provide support to floors, roofs, and walls in buildings as well as serve as main spanning members in bridges.

Types of Steel Beams

Common types of steel beams consist of standard “I-beam” shapes as well as unique configurations including:

- I-Beams: Most widely used “W-shape” beams with optimal balance of strength, cost, and construction ease. Come in varying depths and flange widths.

- Wide Flange: Similar to I-beam but with thicker flanges for increased strength in bending and compression. Used in long spans.

- Plate Girders: Fabricated I-beams built up from separate steel plates. This allows custom heights and proportions for longer spans or heavier loads.

- Box Beams: Hollow structural sections shaped like rectangles or squares. Provide excellent torque resistance. Used as bridge beams.

Applications of Steel Beams

Steel beams serve numerous structural purposes:

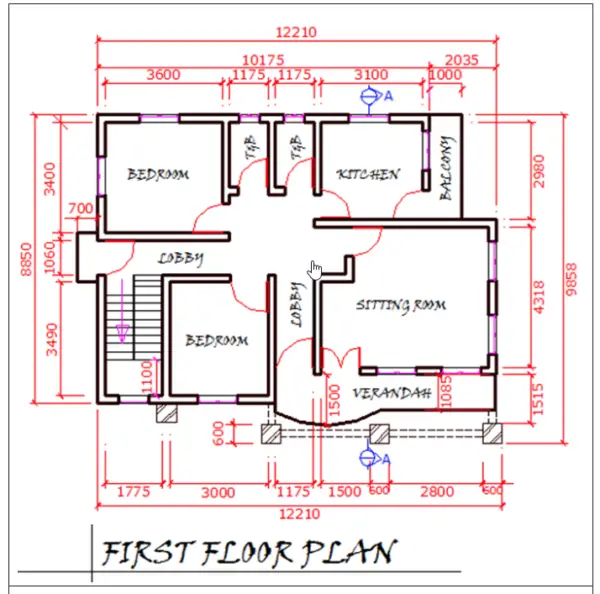

- Floor Framing: Primary floor supports over interior spaces, designed for human live loads.

- Roof Framing: Span longer distances to cover open plan spaces while still allowing drainage slopes.

- Long Span Bridges: Plate girder and box beam configurations.

- Crane Runways: Carry dedicated heavy live loading from overhead crane operation.

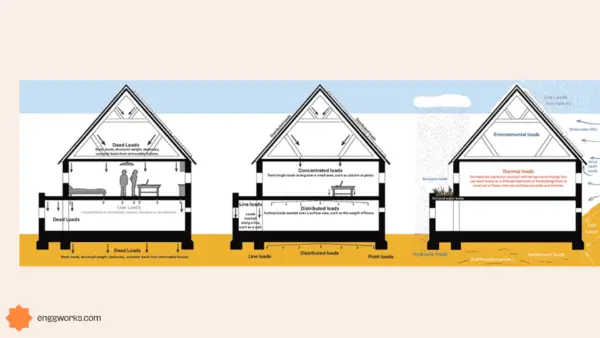

Design Considerations

Engineers evaluate:

- Loading Magnitudes: Beam depth governs required capacity

- Deflection Limits: Prevent excessive bending

- Shear Resistance: Throat thickness provides shear strength

- Connection Detailing: Welded or bolted to structure

Best Steel Types for Beams

Common grades like ASTM A36, A572, A992, A913 offer excellent strength-to-cost rations. Key factors:

- Yield and Tensile Strength

- Formability and Weldability

- Availability for Fab and Construction

Constructing Steel Beams

Typical sequence includes:

- Fabricate beam based on architectural/structural drawings

- Deliver beams to site and temporarily brace

- Make end connections to columns using welding or bolting

- Install supplemental braces, plates. Apply fireproofing.

Conclusion

Steel beams offer efficient long span solutions customizable to any project’s loading needs.

Whether framed conventionally or designed innovatively, they bring strength, safety, and smart economics.