Steel tensile test provides key data on strength, ductility, and additional mechanical properties for structural design and quality control.

Steel is one of the most widely used construction materials in buildings, vehicles, infrastructure, and machinery due to its immense strength and durability properties.

Steel exhibits immense strength thanks to advanced production methods. However, validating mechanical properties via materials testing remains crucial for structural integrity and safety.

However, not all steel products exhibit the same performance characteristics. To assess and validate the mechanical properties of steel materials and products, materials scientists and engineers utilize a standardized experiment known as a tensile test.

In a steel tensile test, a steel sample is subjected to controlled increasing forces that pull or “tension” the sample from both ends until it fractures.

Using specialized tensile testing machines, researchers determine the steel’s resistance to applied tensile stresses and how much it elongates.

The data generated helps quantify the strength limit, yield point, ultimate strength, and ductility indices that inform engineering design and quality control specifications for different steel alloys and products.

However, there are nuances in tensile testing methods and interpreting results that engineers must understand to avoid performance failures in the field.

Tensile Strength Testing of Steel

The most direct tensile test output is tensile strength, measured in units of force per sample cross-sectional area (MPa or ksi).

To obtain tensile strength, samples are pulled to their breaking point.

The maximum stress endured indicates the steel grade’s tensile strength capacity.

Steel Yield Strength Testing

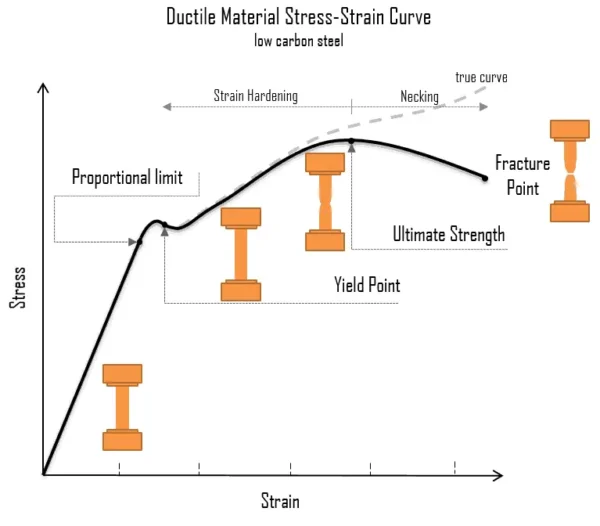

Yield strength defines the stress level causing non-reversible plastic deformation.

Exceeding yield strength causes permanent shaping defects.

By convention, a 0.2% offset strain criteria identifies yield strength on the stress-strain diagram.

Determining Steel Ductility

Ductility demonstrates material malleability, measured by how much it elongates before fracturing in a tensile test.

More elongation equals greater ductility. Engineers assess ductility using percentage reduction of cross-sectional area at failure or percentage elongation after fracture.

steel Tensile Test Sample Dimensions

To ensure test consistency, standards like ASTM E8/E8M dictate sample dimensions by material type, thickness, and shape.

Common structural steel tensile specimen formats include round, square, sheet-type, and flat designs.

Analyzing Stress-Strain Curves

Tensile test machines plot the stress-strain curve in real-time up to failure, displaying the steel’s response.

The curve profiles elastic deformation, yield point, plastic deformation, and rupture stages.

Understanding how to interpret these curves proves critical.

Steel Tensile Test Procedure

Performed on universal testing machines, the process involves:

- Inserting and affixing a steel specimen in self-aligning grips

- Applying increasing engineering strain at a controlled rate

- Recording applied tensile force and elongation

- Continuing until rupture failure

- Analyzing generated test data

Careful test procedures and machine calibration support data accuracy.

Influencing Factors on Tensile Properties

Steel composition, microstructure, processing routes, specimen machining, test temperatures, and strain rates all impact resulting tensile properties.

Engineers must consider these conditions when designing advanced high-strength steels.

steel Tensile Test Equipment

In addition to the universal test frame applying precise strains, extensometers directly measure sample elongation.

Laboratories testing high-performance alloys use advanced non-contact optics for elongation and microstructural evaluations during live tests.

ASTM Standard Test Methods

Multiple ASTM standards define tensile testing procedures for various steel materials, product forms, and applications:

- ASTM A370: Standard Test Methods and Definitions for Mechanical Testing of Steel Products

- ASTM E8/E8M: Tension Testing of Metallic Materials

- ASTM E21: Elevated Temperature Tension Tests for Metallic Materials

Familiarity with these and other applicable standards proves necessary to produce compliant, comparable tensile data.

FAQ – Steel Tensile Test Questions

What is the standard for steel tensile test ?

ASTM E8 / E8M is one of the most common test method for determining the tensile properties of metallic materials, with the other being ASTM A370. First released in 1924, it was originally named ASTM E8-24T and is the oldest actively-used standard for the testing of metals.

What is tensile testing method?

Tensile testing is a destructive test process that provides information about the tensile strength, yield strength, and ductility of the metallic material. It measures the force required to break a composite or plastic specimen and the extent to which the specimen stretches or elongates to that breaking point.

What is the speed of steel tensile test?

Specimens are placed in the grips of the universal tester at a specified grip separation and pulled until failure. For ISO 527 the test speed is typically 5 or 50mm/min for measuring strength and elongation and 1mm/min for measuring modulus.

steel Tensile Test Reports

Final test reports compile key outputs like tensile strength, yield strength, elongation, and reduction of area at failure alongside the test specimen dimensions, procedures, and stress-strain curves.

Test reports facilitate analysis and inform material selection for design.

In summary, steel tensile test provides the foundational data to predict performance and safety margins for structural engineering applications.

Tensile properties influence design specifications across the construction, mechanical, and infrastructure sectors. Mastering tensile test methods and stress-strain analysis unlocks smarter material selection and longevity.