A beam is a structural component or member that primarily transfers loads put along its axis to its supports, such as walls, columns, foundations, and so on, with bending serving as the main mode of deflection.

Beams are essential structural elements in civil engineering, as they support the loads acting on buildings and other structures. They are usually horizontal and can resist vertical forces, shear forces, and bending moments.

Classification of beams

Beams can be classified based on different criteria, such as their support types, materials, cross-sectional shapes, and equilibrium conditions. Some common types of beams are simply supported beams, continuous beams, cantilever beams, fixed beams, and overhanging beams.

Beams can also have different shapes, such as I-beams, T-beams, channel sections, rectangular sections, hollow sections, and pipes. They are designed and analyzed using various methods and software to ensure their strength, stability, and serviceability.

Following are different types of beams in civil engineering, which are classified on different criteria

Types Of Beams On Material

Timber beam

A beam made of wood or engineered wood products. It is used in traditional and aesthetic structures where fire resistance is not a major concern. It is commonly used in wooden roof trusses.

Timber beams have advantages such as a high strength-to-weight ratio, natural beauty, and environmental sustainability.

However, timber beams also have disadvantages, such as susceptibility to fire, decay, and insects. Therefore, timber beams require proper design, installation, and maintenance to ensure their durability and performance.

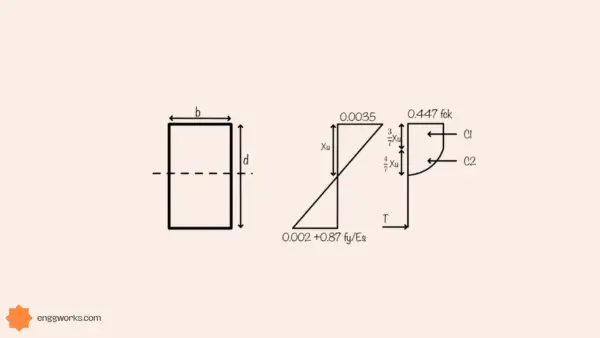

Reinforced concrete beam

A beam made of concrete and steel reinforcement bars. It is widely used in building construction due to its strength and durability.

The concrete provides strength in compression, while the steel bars provide strength in tension.

The combination of these two materials allows the beam to resist bending and shear forces. RC beams are widely used in civil engineering structures such as bridges, buildings, and dams.

Steel beam

A steel beam is a structural element that can support loads by resisting bending or shear forces.

Steel beams are commonly used in buildings, bridges, and other structures because of their high strength-to-weight ratio and durability.

Steel beams can be classified by their shape, such as I-beam, H-beam, or T-beam, or by their material, such as carbon steel, alloy steel, or stainless steel.

Composite beam

A composite beam is a structural component made of two or more distinct materials that have been joined to create a single piece.

Compared to a beam made of a single material, the composite beam may have better stiffness, strength, or durability.

For instance, although a concrete beam by itself can only withstand compression forces, a composite beam composed of steel and concrete can withstand both tensile and compressive stresses.

In the construction of buildings, bridges, and other engineering applications, composite beams are frequently employed.

Types of Beams and Supports

Simply supported beam

A beam supported on both ends by pin and roller supports, which are free to rotate and have no moment resistance.

Cantilever beam

A beam fixed at one end and free at the other end. It transfers the load to the fixed end by bending. Examples of cantilever beams are balconies, diving boards, and road signs.

Continuous beam

A beam extending over more than two supports distributed along its length. It has lower bending moments and deflections than simply supported beams.

Fixed beam

A beam supported on both ends and restrained from rotation. It produces moments at the fixed ends due to the applied loads.

Overhanging beam

A beam with one or both ends extending beyond its supports. It has the properties of both a cantilever beam and a simply supported beam.

Types of Beams on the shape of oss Section

Rectangular beam

These are the most common types of beams used in construction. They have a rectangular cross-section and are used for simple spans, where the beam is supported at both ends.

T-section beam

T-beams are used when the top flange of the beam is subjected to tensile forces, and the bottom flange is subjected to compressive forces. This type of beam is often used in the construction of bridges and elevated structures.

I-section beam

An I-section beam is a structural element that has a cross-section shaped like the letter I. It is also known as an I-beam, H-beam, or universal beam. I-section beams are commonly used in construction, engineering, and architecture because they can resist bending and shear forces along their length, they have a high strength-to-weight ratio, and they can span long distances with minimal deflection.

L-section beam

L-beams are used when the loading conditions require a beam with an L-shaped cross-section. This type of beam is commonly used in the construction of retaining walls and piers.

Circular Beams

Circular beams are used in situations where a round cross-section is required, such as in the construction of silos or water tanks.

C-section beam

A C-section beam is a structural element that has a cross-sectional shape resembling the letter C. It is also known as a C-channel or a C-purlin. C-section beams are often used in construction, engineering, and fabrication applications because they offer a high strength-to-weight ratio, easy assembly, and versatile design options.

Types of Beams in Geometry

Straight beam

A straight beam is a structural element that resists bending and shear forces along its length. It has a constant cross-section and material properties throughout.

Tapered beam

A tapering beam is a structural element that has a varying cross-section along its length, usually decreasing from one end to the other. It can reduce the weight and increase the stiffness of a structure, but it also introduces additional stress concentrations and complexity in the design and analysis.

Curved beam

It is a structural member that has a non-straight axis and is bent in the plane of loading. Curved beams are often used in arches, crane hooks, chain links, and machine frames.

The stress distribution in a curved beam is different from that in a straight beam and depends on the shape and size of the cross section, the radius of curvature of the axis, and the applied bending moment.

The neutral axis of a curved beam is not coincident with the centroidal axis, and the stress varies hyperbolically from the inner to the outer fibers.

Types of Beams on Equilibrium conditions

Statically determinate beam

A statically determinate beam is a beam whose internal forces and reactions can be determined using only the equations of static equilibrium. This means that the number of unknowns is equal to the number of independent equations. A statically determinate beam has no indeterminate stresses or deformations due to external loads or supports.

Statically indeterminate beam

A statically indeterminate beam is a beam that has more unknown reactions than there are equilibrium equations to solve for them. This means that the beam cannot be analyzed by using only the static equilibrium conditions. To solve a statically indeterminate beam, one needs to consider the material properties and compatibility of deformations of the beam. There are different methods to compute the flexibility or stiffness coefficients of a statically indeterminate beam, such as integration, graph multiplication, or table methods.

What are the main types of beams used in construction?

The main types are simply supported beams, cantilever beams, fixed beams, overhanging beams, continuous beams, and trussed beams. Each has unique support and load characteristics suitable for different structures

How does a cantilever beam differ from a simply supported beam?

A cantilever beam is fixed at one end and free at the other and is often used in balconies and overhangs, while a simply supported beam rests on supports at both ends and allows rotation

Where are I-beams and T-beams commonly used?

I-beams, known for high strength and stiffness, are common in steel-frame buildings and bridges. T-beams are typically used in concrete floors and bridges for added load-bearing capacity

Why is choosing the right type of beam important in building design?

Selecting the correct beam type ensures safety, strength, cost-effectiveness, and longevity, as different beams handle loads, stresses, and spans in various ways

Can beams be made from different materials?

Yes, beams can be constructed from wood, steel, concrete, or composite materials. Composite beams combine materials like steel and concrete for enhanced strength and flexibility in modern designs

Types of Beams on Construction technique

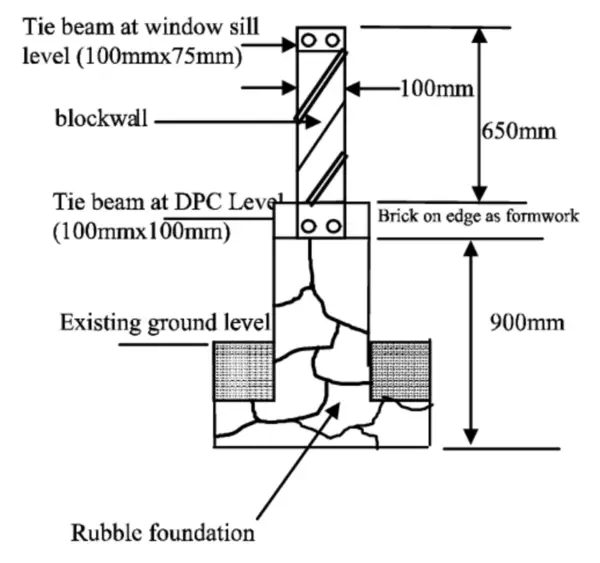

Cast-in-situ concrete beam

Cast in situ beam means the beam is cast on site. This beam has the advantage of being more flexible and adaptable to different site conditions, but it requires more time and labor to construct.

Precast concrete beam

A precast beam means the beam is cast in a factory and transported to the site.

Precast beam has the advantage of being faster and easier to install, but it requires more planning and coordination to ensure proper fit and alignment.

Lintel beam

A lintel beam is a horizontal structural element that supports the load above an opening, such as a door or a window. It can be made of various materials, such as wood, stone, concrete, or steel. The size and shape of a lintel beam depend on the span of the opening, the weight of the load, and the aesthetic preferences of the designer. Lintel beams are important for maintaining the stability and integrity of a building.