If you are in the field of construction or in the engineering industry you must have frequently heard the term aggregates. Aggregates play an important role in building materials as they are responsible for ensuring the strength and durability of the structures.

In this blog, we will discuss the definition of aggregates, classification of aggregates and their role in concrete and selection and proportioning of aggregates.

What are aggregates and their Role?

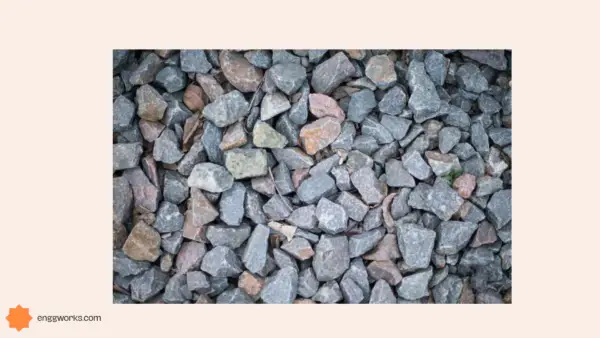

Aggregates are the granular materials such as sand, gravel, crushed stone , or recycled concrete which are basically used as a filler with binding material in the production of concrete and mortar.

Aggregates form the body of the concrete reduce the shrinkage and affect the economy. They occupy 70-80% of the volume of the concrete and they impact various characteristics and properties of concrete.

In order to know more about concrete, it is highly recommended to know further details about aggregates. According to the latest research, it has revealed the fact that some of the aggregates are chemically active and also certain types exhibit some chemical bond at the interface of the aggregates and the cement paste.

Aggregates are divided into different types based on classification. Sand can also be called as aggregate while gravel is also termed the same. But they have different names. For more complete details read our concrete technology posts in the coming weeks.

Aggregates play a crucial role as it has influence over strength and durability of the final product, it is necessary to select high quality of aggregates that meet the necessary standards and specifications.