Installing a new paver patio, flagstone walkway, or other outdoor living space with tight joints between units, requires a proper joint sand.

selection of joint sand and installation is key to create a gorgeous, sustainable surface.

Choosing the right jointing material and following good joint sanding techniques locks each paving unit tightly together, prevents erosion or shifting over years of use, and resists weed growth between pavers.

Common rookie mistakes lead to issues like washout of joint material with the next heavy rain or weeds popping up between pavers.

Best practices , techniques and tools lead to professional-looking results.

What is Patio Jointing?

Patio jointing refers to the sand or fine aggregate filled into the joints between paving stones, bricks, or concrete pavers to lock the whole surface together.

Joints allow individual units to move slightly over time while maintaining an interconnected system.

Purpose of Patio Jointing

Key functions of properly jointed patios:

- Allow minor movement without structure failure

- Prevent upward forces from vegetation and soil

- Provide aesthetic uniform appearance

- Resist erosion from wind, rain, and surface runoff

Applications of Patio Jointing

Typical projects using patio jointing:

- Interlocking concrete paver driveways, walkways

- Brick or natural stone pool decks

- Sand set flagstone garden patios

- Permeable patio systems

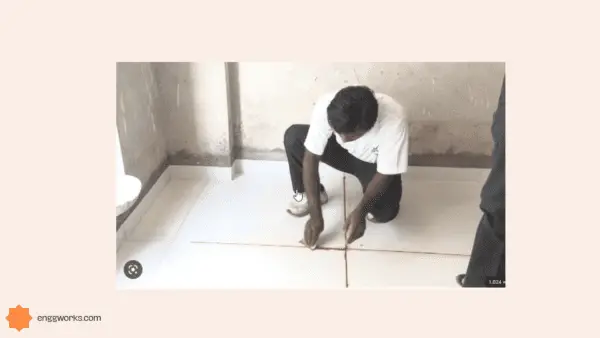

Procedure for Patio Jointing

Main steps for joint sand installation:

- Spread moist joint sand over surface

- Compact pavers with plate compactor

- Brush additional sand into joints

- Compact again until joints completely filled

- Remove excess sand for clean appearance

Materials Used for Patio Jointing

Jointing sands for best performance:

- Washed concrete sand: Angular aggregate resists erosion

- Masonry sand: Smooth composition won’t stain pavers

- Polymeric jointing sand: Binder resists weed growth when wet

Use sand meeting ASTM C144 composition specs without silt or clay.

How to Re-sand Patio Jointing

Over time, refilling joints maintains integrity:

- Remove old joint sand with screwdrivers or compressed air

- Sweep then pressure wash entire surface

- Allow patio to fully dry before adding 1/4″ layer of fresh joint sand using steps above.

Conclusion

Properly filling the joints between patio pavers, bricks, or stone units is essential to create a gorgeous, long-lasting outdoor living space.

Taking the time to correctly choose an ideal joint sand material specifically graded for patios will prevent issues with shifting, erosion, and weeds down the road.

A quality joint sand combined with proper installation techniques to fully pack materials deep into all joints leaves a flawless tight surface able to withstand years of wear.

Periodically checking for low spots or loose materials and re-sanding areas as needed ensures your patio maintains structural integrity and visual appeal over decades of use.

choosing proper joint sand materials, correct installation procedures, performing maintenance checks, and periodically re-sanding patio joints over time, undertake high-quality patio jointing projects that will last with best result.