What is a Beam Column?

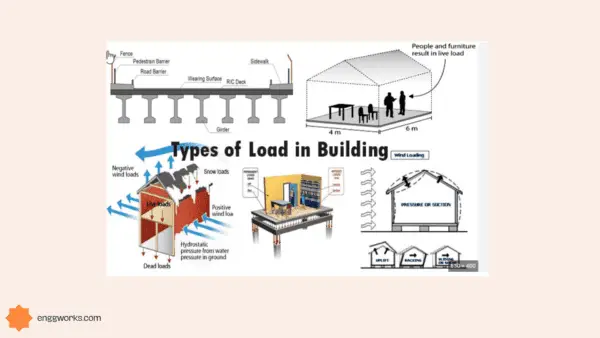

A beam column is a structural member that is subjected to both bending moments and axial forces. Beam columns are common in framed structures and are designed to resist both lateral and gravity loads.

In a building frame, beam columns act as intersecting beams and columns. They transfer forces between beams and columns where they interconnect. Beam columns are critical in providing stability and load resistance.

Reinforced Concrete Beam Column Joints

The joint connecting a concrete beam and column is crucial for transferring forces. Reinforced concrete beam column joints consist of:

- Column reinforcement extending into the joint

- Beam bars anchored into the joint

- Shear reinforcement in the joint region

Proper detailing of the reinforcement allows forces to be transferred between members. The goal is to avoid brittle joint failures.

Factors to consider when selecting the appropriate beam column joint

some key factors to consider when selecting appropriate beam column joint detailing techniques:

- Loading Conditions – The expected axial, shear, and moment demands on the joint will guide the reinforcement needs. Higher loads require more robust detailing.

- Structural System – Detailing will vary for different framing systems like moment-resisting frames vs. braced frames. The joint role in the system impacts design.

- Member Sizes – Larger beam and column sizes make joint detailing more complex due to bar congestion. Smaller members are easier.

- Concrete Strength – Higher strength concrete allows more capacity but requires attention to development lengths. Lower strength needs more reinforcement.

- Ductility Needs – Seismic regions need more ductile detailing like hooking beam bars or adding confinement. Non-seismic may use simpler pin joints.

- Constructability – Ease of constructing the connection affects feasibility. Complex details can make placement of concrete and bars difficult.

- Cost – Unique joints are more expensive. Standardized details save on fabrication and construction costs.

- Function – Whether the joint is fixed or pinned influences reinforcement layouts. Moment connections need more detailing.

- Beam Orientation – Vertical web beam bars have different anchorage needs than horizontal slab beam bars in joints.

Careful attention to these parameters allows selection of cost-effective joint details that meet structural demands and functionality.

standardized beam-column joint details and their applications

some common standardized beam-column joint details and their typical applications:

- Knee Joints – Used when beams frame into columns in one direction. Good for connecting girders and columns in building frames.

- Head Joints – Beam members frame into all four sides of the column. Useful for lateral load resistance in moment frames.

- Exterior Joints – Beam extends from the side of an exterior column. Common for perimeter columns in seismic zones.

- Corner Joints – Columns at building corners have two beams framing in perpendicular. Provides lateral stability.

- Pinned Joints – Simple shear connections with minimal reinforcement. Used when rotation is not needed.

- Fixed Joints – Heavily reinforced to resist moment and shear. Provides full rotational capacity.

- Mechanical Joints – Use bolted end-plates instead of welding/reinforcing. Quick construction but less rigid.

Standardized details like these optimize construction efficiency. Engineers select the appropriate type based on structural layout, load paths, and framing requirements. Custom joints are used for unique geometries or loading.

Design considerations for selecting the appropriate beam-column joint

Here are some of the key design considerations when selecting an appropriate beam-column joint type:

- Structural system and framing – The joint type should match the overall structural framing like moment-resisting frames versus braced frames. This impacts load paths.

- Expected loading – Beam-column joints must be designed to transfer axial, shear and moment forces between members. Higher loads need more robust joint types.

- Desired rigidity – Pinned joints allow rotation and are less rigid. Fixed or rigid joints restrict rotation for more stiffness.

- Ductility needs – Seismic areas require ductile joint detailing to accommodate movement. Non-seismic areas can use brittle joints.

- Constructability – The ease of constructing the joint type affects cost and schedule. Complex joints can impede construction.

- Member sizes – Large members cause joint reinforcement congestion requiring special details. Smaller members allow simpler standard joints.

- Concrete strength – Higher strength concrete allows thinner joints but needs more attention to development lengths.

- Reinforcement requirements – Availability of anchor rebar and shear reinforcing impacts achievable joint types.

- Exposure conditions – Beam-column joints exposed to weather require corrosion-resistant details.

- Cost – Unique custom joints are generally more expensive than standardized joint types.

Beam Column Joint Design

Beam-column joints are critical zones in a reinforced concrete frames where beams and columns intersect. They are designed to transfer forces between connecting members. Proper joint design ensures adequate strength and ductility.

Beam column joint design aims to provide sufficient strength and ductility. The joint must resist column axial loads combined with beam moments and shears. Complex strut-and-tie models analyze force transfer

- Determine factored loads on joint from analysis

- Select appropriate joint configuration and details

- Design joint shear capacity and diagonal cracking resistance

- Provide sufficient anchorage for beam and column bars

- Detail transverse, diagonal, and shear reinforcing

- Check development lengths of reinforcement

- Verify cover and spacing requirements are met

- Draw complete rebar arrangement and detailing

Beam Column Connection Design

The beam column connection design process involves:

- Determining connectivity needs like pinned versus fixed

- Analyzing member forces for combinations of axial and moment

- Designing the required strength and ductility

- Detailing the reinforcement to meet design objectives

- Engineers optimize the connection design for efficiency while adhering to code requirements.

Concrete Beam-Column Joint Reinforcement

Adequate joint reinforcement is necessary to allow inelastic rotation capacity. For concrete beam-column joint reinforcement:

- Column bars should extend through the joint

- Beam bars should be anchored properly into core joint area

- Shear reinforcement should surround joint and provide confinement

- The reinforcing layout ensures ductile performance under seismic loads.

Seismic Design of Beam Column Joints

Here is an overview of seismic design considerations for beam-column joints in reinforced concrete structures:

Beam-column joints in seismic regions experience high shear reversals and must be designed to accommodate cyclic displacements. Ductile detailing is critical.

In seismic regions, beam column joints experience high shear reversals. Special provisions apply:

- Transverse reinforcement ratios are increased

- Mechanical anchorage is used for longitudinal bars

- Diagonal bars can improve shear resistance

- Joints are designed to resist 1.5 times code allowable shear

- Ductile detailing enables beam column joints to withstand seismic demands.

Seismic Demands

- Large shear forces from lateral inertial loads

- Moment reversals from vibration cycles

- Axial and compression loads on columns

Design Approaches

- Provide adequate transverse reinforcing for confinement

- Use seismic hooks, mechanical anchorage for beam/column bars

- Add diagonal crossties at joint corners

- Design for 1.25-1.5 times allowable shear capacity

- Ensure strong column-weak beam concept

Ductile Detailing

- Extend column bars fully through joints

- Use seismic hooks or headed bars for beams

- Confining hoops, spirals, ties throughout joint

- Limit bar congestion, spacing for concrete flow

Tested connections like Knee joints in moment frames perform well seismically. Proper detailing enables joints to withstand seismic demands through flexure and ductile behavior

Conclusion

Beam-columns serve a critical structural purpose by withstanding combinations of axial and lateral loading. The design of reinforced concrete beam-columns and their associated joints requires careful attention to achieve adequate strength, stiffness, and ductility.

Beam-column joints are complex zones requiring experience and understanding of structural mechanics. Well-designed beam-column framing systems distribute forces efficiently throughout the structure while minimizing the likelihood of dangerous brittle failures.

Further research on the behavior of modern beam-column components under extreme loading will lead to continued improvements. But following current best practices in analysis, detailing and ductile design enables beam-columns to withstand the most demanding design loads safely and effectively.