Green composites(GC) are a class of Bio-composites. They are engineered by reinforcing a natural fiber in a bio-based polymer matrix . Composites are used in several applications. The characterization of polymer composites based on recyclable polymers.

In recent efforts are made to reduce carbon fiber. There are range of applications towards smart composites. The mechanical properties of natural fibers are strong and also be used in civil engineering. Bio composites have various applications like wood frames, furniture, rail road etc.

The main properties of these natural fiber composites include recyclability, lightweight, eco-friendly. They are available relatively at low cost. Composites are made of matrix and reinforcement. Natural fiber-reinforced polymer composites offer good mechanical performance.

When bio-composites are used as construction materials, they are low-cost, light-weight and durable.

They combine plant fibers with natural resins. To create natural composite materials. Natural fibers like flax, hemp, banana, sisal, oil palm and jute have a number of techno-economic and ecological advantages over synthetic fibers like glass fiber.

Combination of interesting mechanical and physical properties together. With their environmentally friendly character has attracted many industrial sectors.

Environment-friendly Green Composites

Bio-composite materials have gained interest as a potential alternative. The performance of green composites is good compared to synthetic based polymers.

They are used for different industrial applications. Like automotive, agriculture, constructions, paper coatings, packaging materials and biomedical applications. Where these bio-composites are an appropriate sustainable replacement.

They are replacement for metal based composites.

Technological developments are in progress. To enhance the material properties of bio-based polymers. An example is heat resistant fiber-reinforced polylactic acid composite.

Thereby allowing extensive industrial applications. The composites reinforced with animal based natural fibers require more studies.

The organic matrix composite is a general classification of composites. It includes sub-class like polymer matrix composites. The natural fibre is more environment friendly and stronger than glass fiber reinforced composites.

Necessity of Biodegradable Polymer

The current environmental scenario demands new and eco-friendly solutions. They solve global problems which covers the need for materials.

Biodegradable Green composites are one such material. They are included in the construction and industrial sector. Biodegradability is one of its important attribute.

One of the classification of composites is the ceramic matrix composites. The natural fibers reinforced composites research is an attractive topic.

These materials have a global value. Since they can act as a counter to the various environmental issues. Such as waste management problems. For example, increase in global warming, deterioration of fossil resources.

The persistence of GC in the environment is significantly shorter compared to synthetic composites.

Majority of the fibers are easily degradable and show important advantages like renewable, abundant, inexpensive, light weight, strong and non-abrasive. Hence an excellent alternative reinforcement for synthetic fibers.

Constituents of Natural Fibers

Bio-composite materials are a hybrid of natural fiber, a reinforcement and a matrix resin.

The resin is a polymer matrix , either a renewable or non-renewable resource. The natural fiber, also biofiber, is a plant or cellulose derivative.

Different types of natural fibers used as reinforcement in polymer composites-

PLANT FIBERS– Flax, hemp, jute, sisal, agave, Abaca, curaua, Henequen, pineapple, kenaf, oil palm empty fruit bunch.

WOOD FIBERS– softwood, hardwood, pine, bagasse

Soy source for Eco-friendly fiber composite

Interest in natural fiber composite is growing due to their advantages against synthetic material. With advancements in research a new green composites that competes with synthetic materials has evolved.

Researchers in the US have developed an eco-friendly, biodegradable composite made from soy flour resin and flax yarn. It is made from plant fiber and resin- renewable sources making the composite a greener alternative to other petroleum derived materials.

The reinforcement of yarn with resin improves the strength of the material when cross-linked.

This composite has good physical and mechanical properties, strong and durable enough for low-load indoor applications. Flax yarn’s low density makes it attractive in applications where weight is considered.

Minimum waste by composting is a considerable benefit unlike other materials which are difficult to degrade and adds a large volume of waste to landfill sites.

Fig. Soy Protein/Flax Fabric ‘Green’ Composite Testing

Sustainable Composite Material Manufacturing

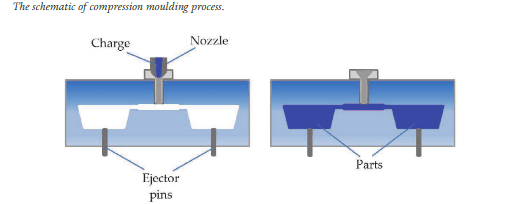

The fiber reinforced polymer composites were prepared by different fabrication techniques.

- Filament winding

- Lay-up methods

- Resin transfer molding

- Injection molding

- Vacuum bonding

- Autoclave bonding.

Advantages of Fully Biodegradable Green Composites

This sector is a booming industry and includes green polymer-based composites and natural reinforcers.

- Less expensive.

- Reduced weight.

- Increased flexibility.

- Renewable resource.

- Sound insulation.

- Thermal recycling is possible where glass poses problems.

- Friendly processing and no skin irritation.

Disadvantages of Natural fibers reinforcement

- Lower strength properties (especially impact strength).

- Good moisture absorption causing swelling of fibers.

- Lower durability.

- Poor fire resistance and irregular fiber lengths are the disadvantages. However, recent fiber treatments have improved these properties.

Mechanical Properties and APPLICATIONS

Green composites are applied to various components with moderate and high strength.

Electrical, Electronics– Antennas, Cable tracks, Windmills, Insulation for electrical construction, Circuit breakers, Printed circuits, Armors, boxes Television towers – Top.

Buildings and public works– domes, windows, chimneys,partitions, concrete molds, swimming pools.

Roads and rail transport– castings , cabin panels, power units, wagons, doors, seats, chassis, suspension, wheels, grills.

Marine transport– boats, hulls, Anti-mine ships.

Air and space transport– aircraft components, automotive applications like blades, propellers, rocket boosters, Shafts and Brake discs.

Mechanical applications– Weaving machine rods, Compressed gas bottles, Tubes for offshore platforms,Gears, Bearings, Casings, Pneumatics for radial frames, Jack body, Robot arms, Flywheels, Pipes, Components of drawing table.

Sports and Recreation– Skates, Bows and arrows, Rackets, Fishing poles, Javelins, Helmets, Skis, Poles used in jumping, Sails, Surf boards.

Decorative purpose – False ceilings, Partition purposes, Doors,Furniture, particle board is a type of unfinished composite panels extensively in residential kitchens, playing a role in cabinets, shelving, countertops and floor underlayment.

Medical industry– The starch based biodegradable hydrogels or microspheres are used in different biomedical applications because of their novel properties like hydrophilicity, penetrability, biodegradability that mimics biological structures to some extent.

Frequently asked questions (FAQ)

How are green composites different from traditional composites?

Green composites can be produced from different raw materials which are abundant in nature and bio-renewable sources.The resins and fibers used are biodegradable, unlike traditional composites which do not degrade and are hazardous to ecology resulting in landfill at the end of its life span.

Can green composites be recycled?

Green composites are formed from natural fibers of plants or cellulose which can be easily degradable. These can be recyclable by using different methods like hotpressing, grinding and dissolution.

Are there any disadvantages or limitations to using green composites?

High flammability, high moisture absorption, and a wide variation in properties, consequences of their natural origin are some of the disadvantages that are limiting their applications.

Composite Industry Reinforced with natural fibers

Green materials represent a consolidated alternative as substitutes against traditional composites. They exhibit comparable properties to those reinforced with synthetic fibers and are easily composted after their life, completing the natures carbon cycle.

Environmental-friendly green-composites are not only a solution to growing environmental threat but also a solution to uncertainty of petroleum supply and would be of great importance to the materials world.

Diverse initiatives have emerged in European countries, in the United States, Canada, and Japan, to foster the use of green non-oil-based composites instead of oil-based materials, promoting the use of renewable conventional and non-conventional sources.

Despite these benefits, they are not capable of replacing their synthetic counterparts. In all applications entirely due to some significant limitations. Such as high moisture absorption, low modulus elasticity, faster decomposition.

When surrounded by basic conditions, during microbial encounter, and visible variability in mechanical characteristics

Although these raw materials entertain several challenges, they can be considered as materials of the future. As they promote green growth, a process of transition towards a low-carbon and resource-efficient society that enhances human well-being.