Grouting is a process of filling gaps or voids with a material called grout.

It can be used for various purposes, such as repairing concrete cracks, sealing joints, stabilising soil, or strengthening foundations.

Grouting can improve the structural performance and durability of buildings and infrastructure.

Depending on the type of the grout material used, grouting can be classified into different types. One of the important among such types is cement grouting.

Cement grout material- Cement, sand and sometimes sand and other additives are used as the grout materials in this cement grouting.

Cement grouting

Cement grouting is a common technique used in construction to fill voids, cracks, and joints in concrete structures.

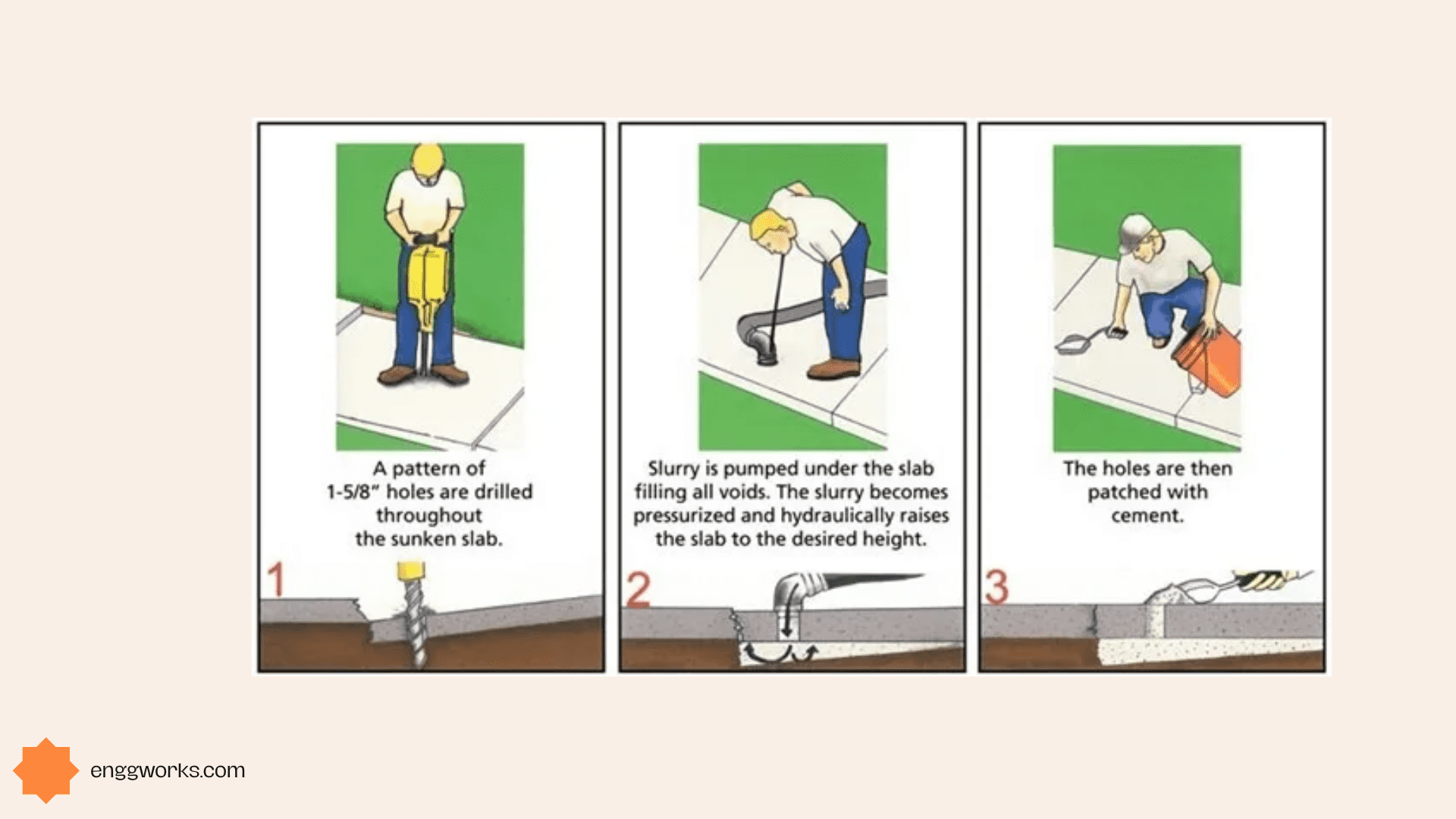

It involves pumping a fluid mixture of cement, water, and sometimes sand or other additives under pressure into the desired location.

It can improve the strength, stiffness, and durability of concrete structures by reducing permeability and increasing bearing area. It can also be used for underpinning foundations, anchoring rock bolts, stabilising soil, and repairing concrete defects.

Cement grout mix ratio

The mix ratio of cement grout depends on the application and the desired properties of the grout, such as flowability, strength, and shrinkage.

The mix ratio for cement grout can vary depending on the specific application and desired consistency. However, one of the common mix ratios for cement grout is the 1-2-3 ratio, which consists of 1 part cement, 2 parts sand, and 3 parts water.

This ratio is considered the “classic” mix ratio by many professional builders, because it is versatile and can be used for a wide range of projects. However, this ratio may not be suitable for some applications that require high flowability or low shrinkage.

It’s important to note that the water-to-cement ratio is critical in achieving the desired strength and durability of the grout. Generally, the water-to-cement ratio should be kept low, usually between 0.4 and 0.5, to ensure that the grout is strong and long-lasting.

Types of cement grouting

Cement grouting can be classified into different types based on the application method, the grout composition, and the grout properties. Some of the main types of cement grouting are:

Permeation grouting:

This is the process of injecting low-viscosity cement grout into fine-grained soils or rock formations to fill the pores and increase the density and strength of the material.

Permeation grouting is often used for soil stabilisation, groundwater control, and seismic retrofitting.

Compaction grouting

This is the process of injecting high-viscosity cement grout into loose or weak soils or rock formations to compact and consolidate the material.

Compaction grouting is often used for foundation settlement control, slope stabilisation, and liquefaction mitigation.

Jet grouting

This is the process of injecting high-pressure cement grout through a rotating nozzle into the ground to create columns or panels of soil-cement mixture.

Jet grouting is often used for excavation support, groundwater cutoff, and soil improvement.

Hydrofracture grouting

This is the process of injecting high-pressure cement grout into cracks or joints in concrete or rock structures to widen and seal them.

Hydrofracture grouting is often used for structural repair, leakage control, and stress relief.

Advantages of cement grouting:

- It is economical and easy to apply.

- It can be performed in confined spaces and hard-to-reach areas.

- It can be customised to suit different site conditions and requirements.

- It can be monitored and controlled during the application process.

- It has minimal environmental impact and does not require excavation or disposal of materials.

Applications of cement grouting:

Following are few of the important applications of cement grouting

Soil stabilisation

To avoid erosion, provide foundation strength, and provide a secure basis for building, loose or weak soil is stabilised using cement grouting.

Repairing concrete structures

Cement grouting is used to repair cracks, voids, and other damage in concrete structures, such as bridges, dams, and buildings.

Waterproofing

To avoid water infiltration in constructions like tunnels and basements, cement grouting can be used to form a waterproof barrier.

Sealing joints

In the construction of tunnels, segments or precast concrete panels can be utilised to seal connections between concrete elements.

Cement grouting machine

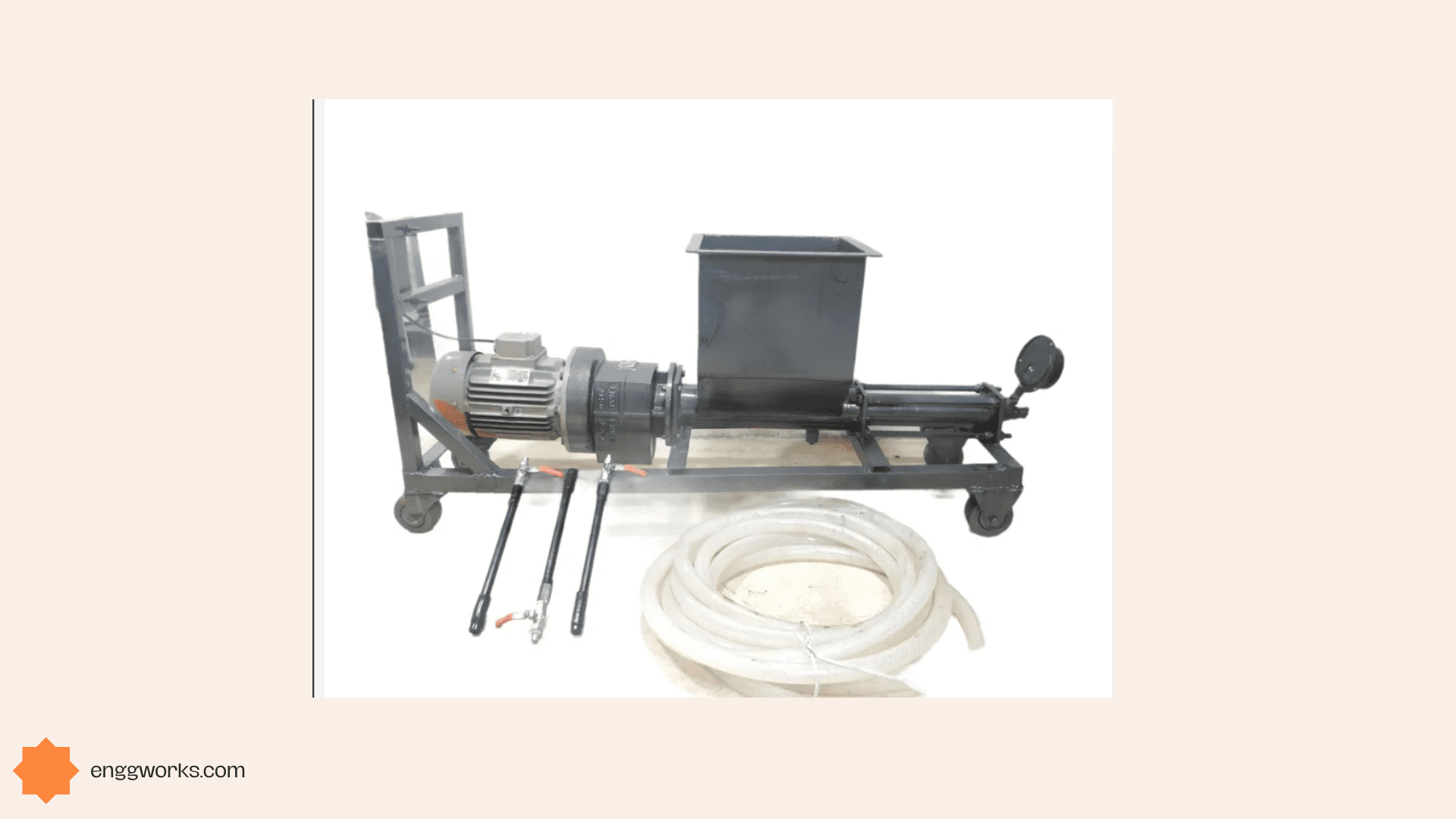

A cement grouting machine is a device used to pump and apply cement-based grout to fill voids, joints, or anchor objects in construction projects.

It typically consists of a motor, a pump, a hose, and a mixer to blend the grout material. The electric power source provides the necessary energy to operate the machine.

It is widely used in civil engineering, mining, tunnelling, and other applications that require high-pressure injection of cementitious materials.

They can improve the strength and durability of structures by filling cracks and gaps with grout. Cement grouting machines can also prevent water leakage and corrosion by creating a waterproof barrier.

Cement grouting machines are available in different models and capacities depending on the requirements of the project.

Some machines have a single drum design, while others have a double drum design for mixing two components of grout. Some machines have a pressure control system, a wireless remote control, and a sprinkler and irrigation function for convenience and efficiency.

Cement grouting machines are easy to operate and maintain, and can deliver consistent performance and quality results.