Fresh concrete contains a lot of air bubbles that get trapped during the mixing process. This entrapped air can reduce the strength of concrete by up to 30% if it is not properly removed.

The process of removing the excess air bubbles from concrete is called concrete consolidation.

Concrete consolidation is critical for ensuring the long-term durability and load-bearing capacity of concrete structures.

It is typically performed using manual tamping or with specialized concrete vibrators. Vibration is the preferred method as it more thoroughly consolidates the concrete.

Performing proper concrete consolidation takes training and experience. But it is a critical step that contractors cannot neglect if they want to build sound concrete structures able to stand the test of time. Letting that excess air stay trapped spells trouble down the road.

What is Concrete Consolidation

Concrete consolidation refers to the process of removing excess air bubbles trapped within freshly poured concrete.

As part of the mixing process, air gets whipped into the concrete and becomes entrapped air. If left in place, these air pockets and voids can compromise the strength and durability of the finished concrete structure.

Purpose of Concrete Consolidation

The purpose of concrete consolidation is to produce dense, homogeneous concrete free of honeycombing and air voids:

- Removes entrapped air and fills in spaces between aggregates

- Allows concrete to fully surround steel reinforcements

- Maximizes concrete strength and long term durability

- Reduces permeability and risk of corrosion issues

- Provides desired surface finish appearance

Proper consolidation ensures the final concrete product meets the specified strength and performance requirements.

concrete consolidation mechanism

Concrete consolidation relies on the application of external vibration to freshly poured concrete. The vibrations introduce rapid movement of the aggregate particles and cement paste, temporarily turning the concrete into a liquefied state.

This allows any air pockets trapped within the concrete to float upwards to the surface while the concrete flows together into a uniform, dense composition with maximized strength capacity.

methods Used in Consolidation of Concrete

There are two main methods used for concrete consolidation:

Manual Consolidation

Involves tamping the wet concrete using sticks, rods or shovels. This helps settle concrete but has limited effectiveness compared to vibration techniques.

Vibration Consolidation

Vibrating concrete introduces a combination of vibrational force and frequency that causes the concrete particles to shift and settle into a denser state.

The vibration fluidizes the concrete, allowing the entrapped air bubbles to rise to the surface where they can escape. Two types of concrete vibrators exist:

Internal Concrete Vibrators

- A vibrating poker head gets immersed into the concrete mass

- Flexible shafts allow repositioning the vibrating head

- High frequency 9000-12000 RPM vibration fluidizes concrete

External Concrete Vibrators

- Vibrating motor attaches directly to concrete formwork

- Vibration transfers through form and consolidates concrete

- Lower frequencies around 3000-6000 RPM common

Contractors pick concrete vibrators based on the concrete’s slump measurement, the amount of steel rebar reinforcement, and other jobsite factors.

Using the properly sized vibrator head and the right vibration duration allows for optimal air removal while retaining concrete workability. The result is a dense, durable concrete matrix free of honeycombing and air pockets.

Vibration consolidation is vastly superior for fully densifying concrete around congested rebar spacing.

Applications of Concrete Consolidation

Concrete consolidation applies to all concrete pours – everything from residential slabs to high-rise towers and dams rely on properly consolidated concrete:

- Structural Columns: Ensures full concrete cover around vertical rebar

- Bridge Components: Eliminates weak zones that compromise integrity

- Pavements & Sidewalks: Reduces surface crazing and cracking

- Dams: Impermeable concrete prevents seepage and failures

Any application where strength, appearance, or water tightness matters requires thorough consolidation.

Equipment Used for Concrete Consolidation

Specialized electric, pneumatic or gas powered concrete vibrators provide consolidation equipment:

- Internal Vibrators – Range from pencil vibrators to large poker heads with flexible drive shafts and separate power units. Heads sized based on concrete mix and rebar spacing.

- External Vibrators – Attach to concrete forms. Common sizes range 2000-6000 vpm frequency and 25-75 kg centrifugal force.

- Clamps & Brackets – Allow mounting external vibrators securely to formwork.

Using properly sized equipment prevents formwork damage while enabling optimum concrete consolidation.

Vibration Technique for Consolidating Concrete

Proper technique is crucial when vibrating concrete to achieve full consolidation:

- Insert vibrating head vertically at consistent intervals of ~1.5 times the radius of influence

- Slowly penetrate concrete under the head’s own weight, avoid forcing or stirring

- Extend vibration to the level of previously placed lifts to knit layers together

- Withdraw head perpendicular to pour surface to allow concrete to flow uniformly behind

- Systematically cover the entire form area, overlapping adjacent vibration zones

- Continue vibration until air bubbles cease surfacing and concrete surface darkens and glistens

- Take care around form edges and reinforcements to prevent damage

Monitoring the pour area and concrete response to vibration provides visual indicators ensuring all concrete gets fully consolidated. Operators should adjust durations and locations as needed to thoroughly densify the concrete within the available working time.

Methods for Removing Air Pockets From Concrete

In addition to vibration techniques, other methods help remove air pockets:

- Pour concrete in shallow lifts under 20 inches to prevent air entrapment

- Use concrete additives like mid-range water reducers for improved flowability

- Apply external vibration on highly reinforced sections

- Manually rod around edges and corners to eliminate air pockets

Using multiple techniques ensures consolidation across the entire concrete mass.

Testing Concrete for Proper Consolidation

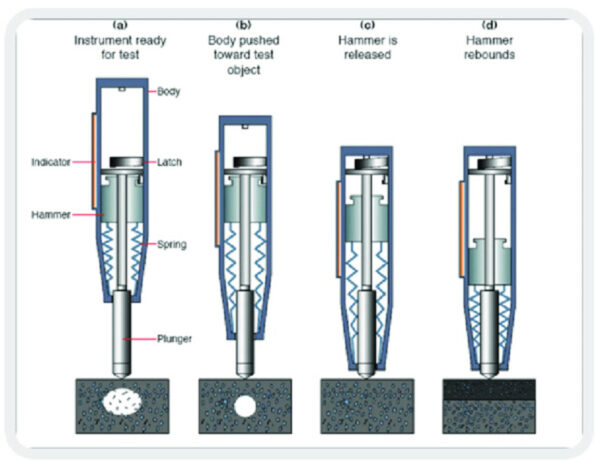

Visual inspection combined with standardized tests confirm adequate consolidation:

- Observe concrete surface for bubbles and glossy sheen

- Tap sections with hammer for hollow sounding areas

- Take core samples to check for honeycombing

- Test compressive strength and air content per ASTM standards

Early testing identifies under-vibrated concrete requiring remediation before structural integrity gets compromised.

Signs of Inadequate Concrete Vibration

Indicators of poor consolidation include:

- Excess air bubbles surfacing

- Lack of mortar film on surface

- Hollow sounding concrete

- Low strength test results

- Surface crazing as excess bleed water rises

Catching consolidation issues quickly prevents significant problems down the road.

Conclusion

With proper planning, equipment, techniques and testing, contractors can ensure thorough concrete consolidation across all projects.

Eliminating entrapped air creates durable, high-performance concrete structures able to withstand decades of service.

The proper vibrating technique permeates the full depth of the pour to actively release entrapped air from the concrete mass. Relying on gravity alone fails to completely eliminate air pockets trapped against steel reinforcing.

Contractors must train crews on appropriate vibration methods and quality control checks to prevent consolidation issues. No one wants to discover air pockets compromising concrete soundness .

Attending to consolidation fundamentals remains critical for long term quality and safety.