A lintel is a critical component in building construction that requires careful design and detailing to ensure structural integrity. This comprehensive guide covers everything you need to know about lintel construction.

What is a Lintel?

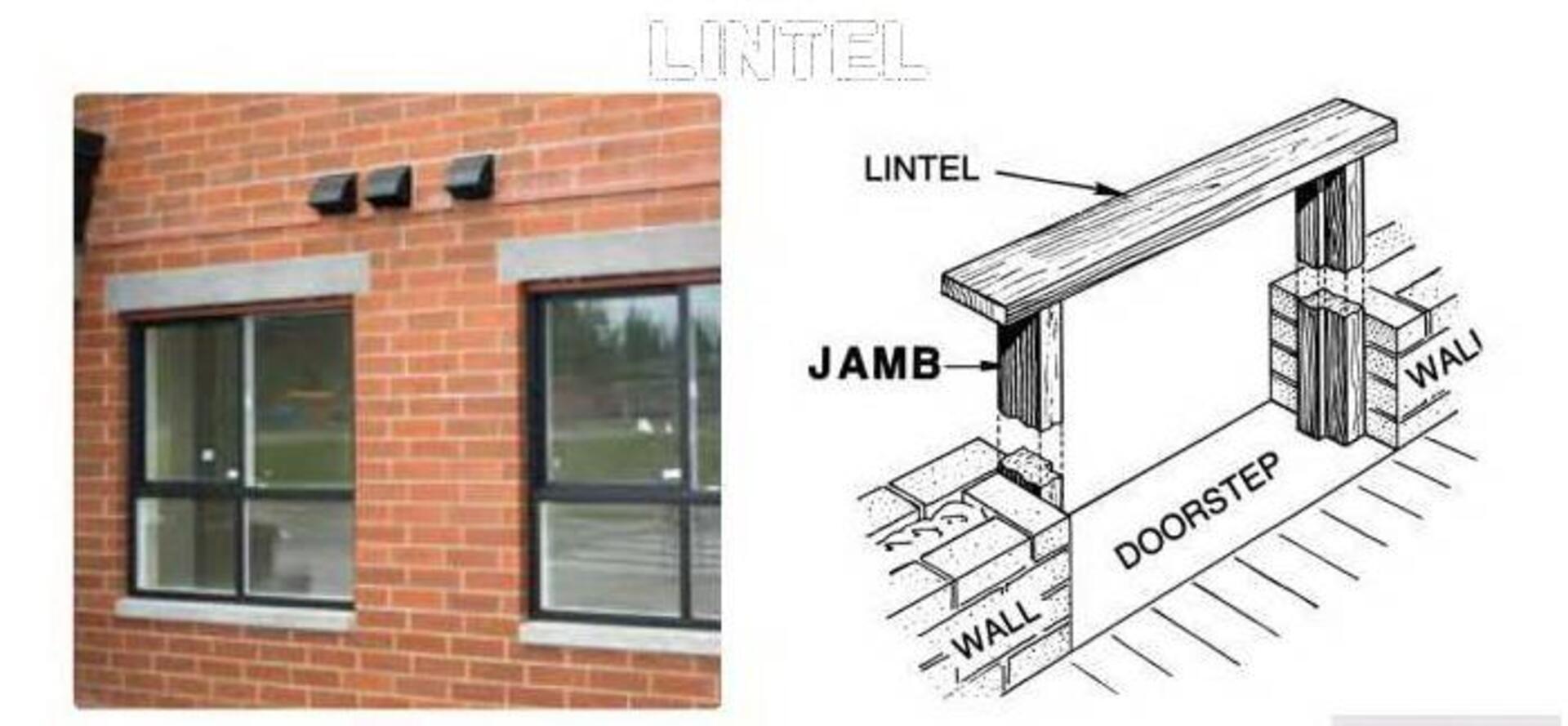

A lintel is a horizontal structural member that spans over an opening like a window or door to carry loads from above and transfer them to vertical members on either side. Lintels support masonry units, brick, stone or any other material over openings in walls preventing them from falling through.

The main purpose of a lintel is to provide strength and stiffness to the wall opening by bridging the gap between supports on either side. It carries the self-weight of the wall above the opening as well as any externally applied loads.

Importance of Lintel Construction

Proper lintel construction is crucial for:

- Supporting the weight of the wall above the opening

- Maintaining structural integrity and preventing cracks or collapse

- Providing anchorage for frames, doors, windows etc.

- Spanning over large openings like garage doors

- Allowing openings to be cut into existing walls

Adequately designed and constructed lintels distribute stresses evenly and provide a durable trouble-free service.

purposes of a lintel in building construction

Here are some of the key functions and purposes of a lintel in building construction:

- To bridge an opening and support the weight of the wall above the opening. This includes the self-weight of the masonry as well as any external loads.

- To maintain structural integrity and stability by transferring the load to vertical supports on either side of the opening. The lintel prevents cracks, deformation or collapse of the wall above.

- To provide a rigid support for doors, windows and other frames fixed within the opening. The lintel distributes the weight of frames and glazing uniformly to the supports.

- To anchor door and window frames, preventing lateral movement or racking. Steel anchors are built into lintels to secure frames.

- To provide an anchorage surface for fixing other components like curtains, blinds, curtain walls etc. around the wall opening.

- To span over large openings like garage or industrial doors where vertical supports are spaced widely apart. The lintel bridges the full width.

- To allow new openings to be cut into existing brick or block masonry walls while maintaining strength.

- To provide an architectural element that enhances the aesthetics around openings with materials like stone, brick, timber.

- To provide fire rating and thermal/acoustic insulation when used as a composite lintel combined with boards or insulation.

key functions of a lintel revolve around providing structural integrity, support for loads, anchorage for fittings and creating openings in walls.

Lintel Design Specifications

Lintel design involves determining:

- Required load carrying capacity

- Optimum spanning distance

- Suitable size and section

- Adequate bearing length on supports

Design standards specify minimum lengths, depths, reinforcement etc. based on span, loads and materials. Proper structural design is necessary to prevent under-sized lintels leading to cracking, deformation or sudden failure.

Materials for Lintel Construction

Different materials are used for lintels based on factors like:

Concrete Lintels

Pre-cast or cast-in-place concrete lintels are commonly used in brick masonry and block construction. Reinforced concrete lintels are economical and provide adequate strength.

Steel Lintels

Steel lintels are used for large spans or heavy loads. They provide great strength but need protection from corrosion. Stainless steel lintels are maintenance free.

Wood Lintels

Wood lintels are used for small openings in wooden frame construction. They are easy to install but prone to shrinkage and decay over time. Proper treatment and maintenance is required.

Stone Lintels

Stone lintels like granite or marble provide incredible strength and durability. They are used in stone masonry structures and historical buildings. But shaping and placing stone lintels requires great skill.

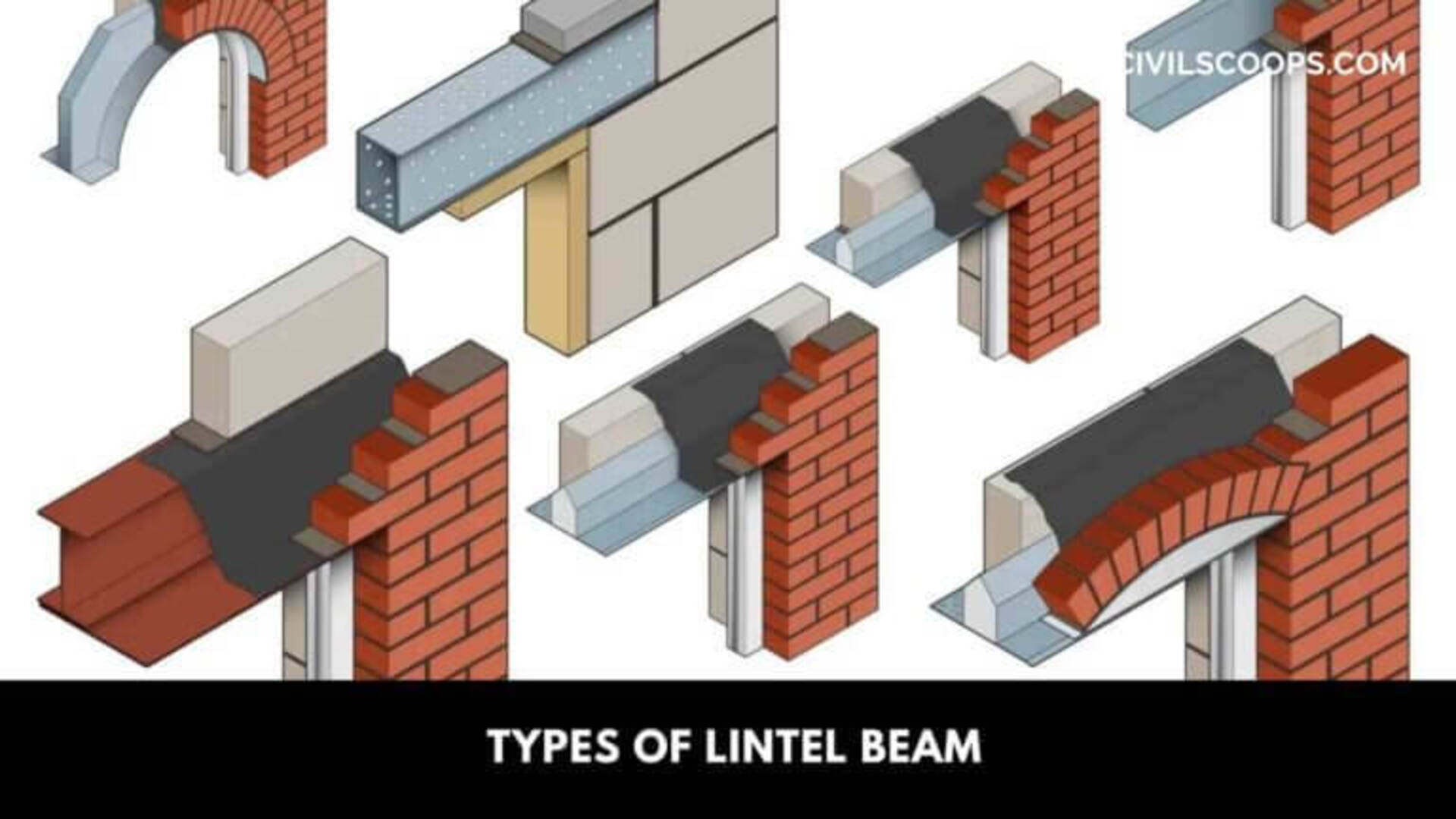

Types of Lintels Used in Building Construction

Different types of lintels used in construction include:

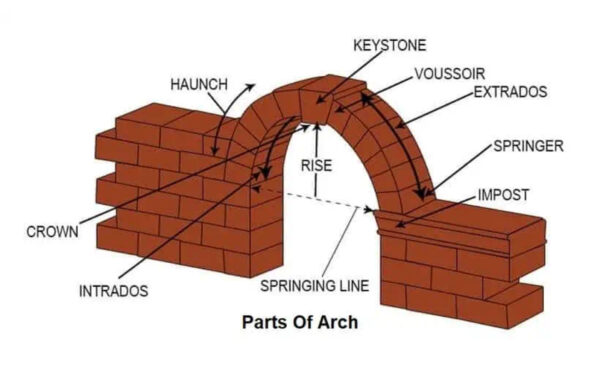

- Arched Lintels – Semi-circular lintels made of brick, stone or concrete that work in compression

- Flat Arches – Constructed from brick or tile to create flattened arch lintels

- Concrete Lintels – Pre-cast or poured-in-place reinforced concrete lintels

- Steel Lintels – Hot-rolled steel sections like angles, channels used as lintels

- Timber Lintels – Wood lintels made from durable timber sections

The choice depends on structural requirements, material availability and architectural considerations.

Components of a Lintel

A lintel comprises of:

- Lintel Section – The main horizontal beam section

- End Bearings – The ends supported on masonry or frames

- Lintel Supports – Masonry pillars or vertical frame elements

- Lintel Height – The depth perpendicular to the wall length

- Coursing – Masonry units above and below the lintel section

Proper detailing of each lintel component ensures adequate structural performance.

Lintel Construction Details

Key details in lintel construction:

- Adequate bearing length on supports – usually 200-250 mm

- Proper reinforcement and concrete cover

- Precise lintel positioning and alignment

- High quality waterproof mortar bedding

- Wedging/pinning of end bearings

- Non-shrinkage grout packing under lintel

- Avoiding cracks in masonry/concrete around lintels

Careful lintel construction avoids future maintenance issues and ensures long service life.

Lintel Construction Specification

Lintel construction must adhere to design specifications covering:

- Material type, grade and properties

- Lintel dimensions and section

- Reinforcement provision – bars, stirrups, hooks

- Concrete cover and mix

- Surface finish and curing

- Handling, storage, protection

- Testing and inspection requirements

- Applicable codes and standards

Strict compliance with specifications ensures lintels are constructed to required design strength and serviceability.

Conclusion

Lintels are important structural elements that allow openings to be created in walls while maintaining integrity. Adequate lintel design and construction using suitable materials is key to prevent premature failures or cracks in supported masonry. Understanding lintel function, design and detailing provides the knowledge to construct durable, long-lasting lintels.