Masonry walls have been used in construction for centuries owing to their durability, fire-resistance, and aesthetic appeal. This article provides a detailed overview of masonry wall construction, types, design considerations, and specifications.

What is a Masonry Wall?

Masonry is the building of structures using individual units bonded together with mortar. Masonry walls are constructed by laying masonry units like bricks, concrete blocks, stones, etc. in horizontal layers along with mortar that binds them together.

The masonry units may be laid in a wide variety of patterns that impact the strength, appearance, and performance.

Masonry walls are non-loadbearing when they carry only their own weight and resist lateral wind or seismic loads. Loadbearing masonry walls support vertical loads from floors and roofs in addition to their self-weight. Proper design and construction of masonry walls is key to build durable and safe structures.

classification of masonry wall

Here are some common ways to classify masonry walls:

Based on Materials Used

- Brick masonry walls

- Concrete block masonry walls

- Stone masonry walls

- Composite masonry walls

- Glass block masonry walls

Based on Structural Function

- Load-bearing masonry walls – carry vertical loads- Load bearing masonry walls are constructed with bricks, stones or concrete blocks. These walls directly transfer loads from the roof to the foundation. These walls can be exterior as well as interior walls. The construction system with load bearing walls are economical than the system with framed structures.

- Non-loadbearing walls – carry self-weight only

Based on Location

- Exterior masonry walls

- Interior partition walls

- Foundation walls

- Retaining walls

Based on Performance Characteristics

- Fire-rated masonry walls

- Acoustic masonry walls

- Insulating masonry walls

- Reinforced masonry walls

Based on Construction Method

- Unreinforced masonry walls

- Reinforced masonry walls

- Post-tensioned masonry walls

- Prestressed masonry walls

Based on Manufacturing Method

- Autoclaved aerated concrete block masonry

- Manufactured stone masonry

- Hand-laid masonry

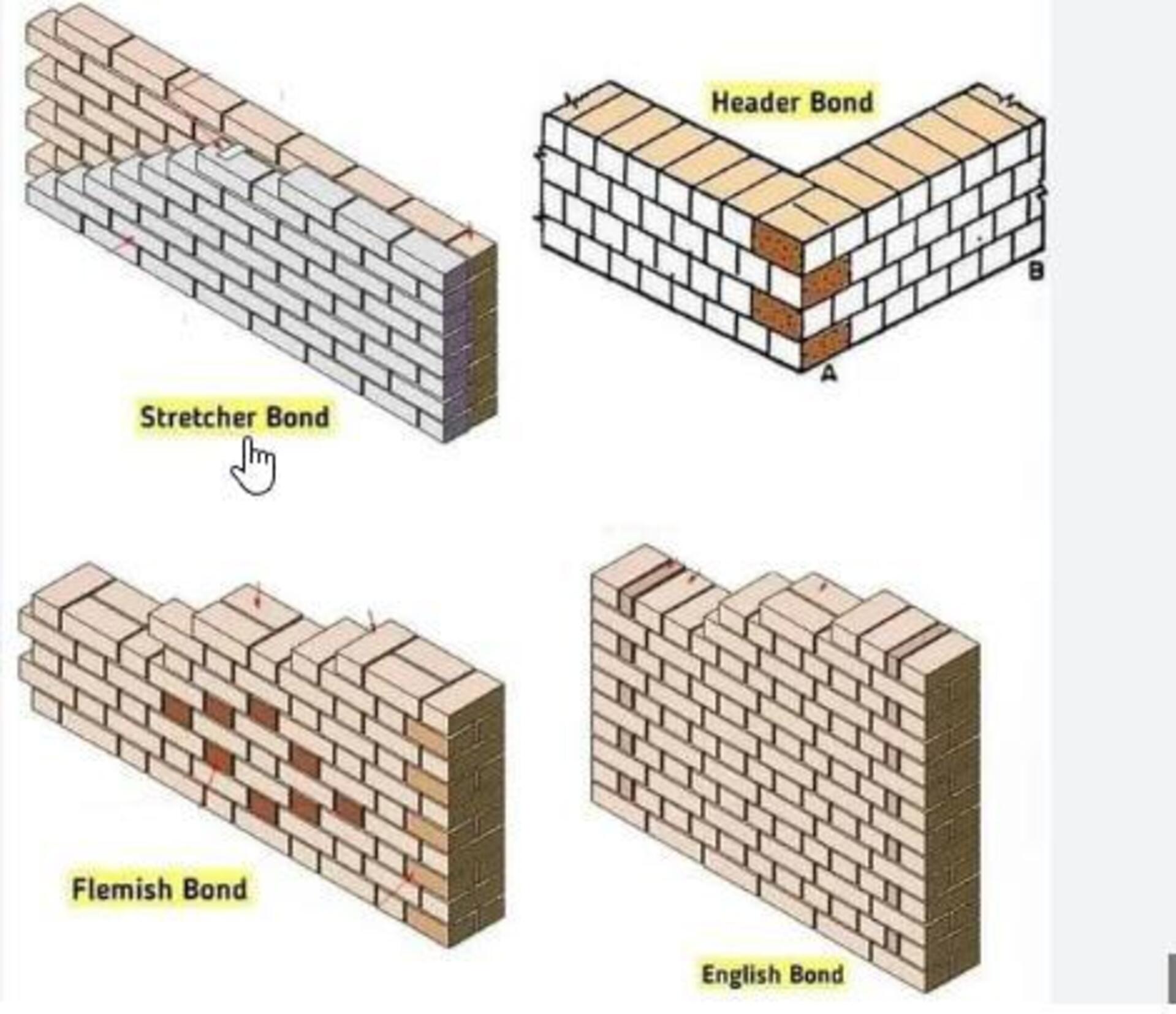

Based on Bond Pattern

- English bond masonry

- Flemish bond masonry

- Herringbone bond masonry

- Stack bond masonry

The key criteria for classification include the materials used, structural purpose, location, performance attributes, construction techniques, manufacturing process, and aesthetic bond pattern. Choosing the appropriate type of masonry wall is important to serve the structural, functional and aesthetic needs of a building.

Types of Masonry Walls

Here are some of the main types of masonry walls classified based on the materials used and their structural functions:

Brick Masonry Walls

The most common masonry units used are bricks, which may be solid or perforated. Brick masonry relies on clay bricks bound with cement mortar. Bricks provide compressive strength while steel reinforcement, if present, resists tensile forces. Some key aspects include:

- Made from clay or concrete bricks bonded with mortar joints

- Provide compressive strength to carry vertical loads

- Used for loadbearing walls or veneer / facing walls

- Solid brick walls used for high loadbearing capacity

- Hollow bricks reduce weight and provide insulation

Concrete Block Masonry

This type uses precast concrete blocks manufactured from a mixture of cement, aggregates and water. The blocks have hollow voids to reduce weight. Some key aspects include:

- Constructed from precast concrete blocks

- Cored or hollow blocks reduce self-weight

- Grout filling cores enhances strength

- Used for basement walls, loadbearing walls, partitions

- Provides fire resistance and noise insulation

Stone masonry walls

Uses natural stone or cast stone blocks. It has Very high compressive strength and are mostly Used for foundations, retaining walls, cladding. They provides excellent durability and aesthetics view. They are of bit heavy self-weight to carry loads by mass

Composite masonry walls

These are made from combination of concrete blocks and clay bricks, Concrete below grade, brickwork above grade. Uses optimal properties of both units. They Efficiently supports vertical loads . Reduces material cost.

Post-tensioned Masonry Walls

this type of masonry walls are constructed to strengthen the masonry walls against the forces that may induce tension in the wall such as earthquake forces or wind forces. These walls are constructed from the foundation level and post-tensioning rods are anchored into the foundation. These rods are run vertically between the Wythe’s or in the core of concrete masonry units.

After the masonry wall construction is completed and cured, these rods are tensioned and anchored on the steel place at the top of the wall.

Autoclaved aerated concrete block walls

- Manufactured from cement, sand, gypsum, aluminum powder

- Low density, high porosity, good insulation

- Easy to cut and install

- Used for partitions and secondary walls

The choice of masonry material determines the structural properties like strength, weight, insulation value and durability. By selecting appropriate masonry units, optimal walls can be built for both loadbearing and non-loadbearing functions.

Masonry Wall Construction

Masonry wall construction involves preparing the foundations, properly bonding the masonry units with mortar, installing wall reinforcements, and applying surface finishes.

- Site preparation includes laying damp-proof courses, weep holes, and foundation walls.

- Masonry units are laid on the foundation in a systematic pattern while embedding reinforcements.

- Mortar is applied on the masonry unit edges just before placement. Joints should be around 10mm thick.

- Head and bed joints must be filled properly and mortar should not overflow. Joints transfer compressive loads.

- Reinforcements like steel bars are placed in grooves or cavities in a regular grid pattern.

- Wall ties anchor exterior masonry walls to structural frames. Control joints allow differential movements.

- Surface finishes like plastering or cladding are applied as needed for aesthetics and weather protection.

Proper construction practices as per standards like ASTM C90 are critical for masonry integrity. Workmanship influences the strength, appearance, and service life.

Masonry Wall Design Considerations

Masonry wall design involves determining adequate dimensions, mortar grades, and reinforcements to support loads while maintaining serviceability. Key considerations include:

- Design for adequate compressive, flexural and shear strength based on supported loads.

- Select masonry units and mortar grade to achieve the required strength. Account for reduction factors.

- Limit slenderness ratios to prevent buckling failures under wind or eccentric loads.

- Ensure adequate lateral support and wall anchorage under wind and seismic loads.

- Design reinforcement for tensile and bond strength. Provide minimum steel ratios.

- Accommodate movements using control joints to limit cracking from creep, shrinkage and temperature changes.

- Design for fire rating, noise transmission, thermal insulation as needed for building use.

- Check stability against overturning, sliding, soil bearing pressures for foundation walls.

Thorough analysis and compliance with standards like ACI 530 is required to engineer safe masonry walls.

Important Masonry Wall Details

In addition to the basic wall layout, certain critical details need careful design in masonry construction:

Joints

- Head and bed joints must be fully filled with mortar without gaps. Partial filling weakens the joints.

- Joint thickness kept between 10-12 mm. Excessively thick joints cause cracking and reduce strength.

- Tooled concave joints provide better mortar consolidation compared to flush joints.

Reinforcements

- Provide cover of at least 16 mm for steel bars to prevent corrosion.

- Lap splices for vertical bars should exceed 40 bar diameters. Stagger splices.

- Use U-shaped lateral ties to resist out-of-plane loads and tie wythes together.

Intersections

- Strengthen corners and intersections with additional masonry units and reinforcement.

- Isolate wall intersections with control joints to allow relative movements.

Openings

- Reinforce masonry on both sides of openings. Bearing length should exceed 1/3 of opening width.

- Use lintels properly sized to carry loads above openings. Provide adequate end bearing.

Anchorage

- Anchor masonry walls securely to structural frames using wall ties embedded in mortar joints.

Concrete Masonry Walls

Concrete masonry is widely used due to the durability, economy, high strength, fire-resistance and speed of construction. Key aspects in concrete block wall construction include:

- Hollow concrete blocks made with aggregates, cement, water and admixtures are the most common units. High void ratio reduces weight.

- Mortar bonds the units together structurally and seals joints from water penetration. Type S mortar is commonly used.

- Grout fills open cavities and cells within blocks, surrounding reinforcements. Grout develops high strength.

- Steel reinforcement in the form of rebars and joint reinforcing provides tensile resistance.

- Control joints accommodate shrinkage and thermal movements to prevent excessive cracking.

- Surface finishes like plaster, stucco or cladding enhance aesthetics.

Proper concrete masonry construction and quality assurance as per ASTM C90 leads to excellent performance.

Brick Masonry Walls

Brick masonry has remained popular for centuries owing to the durability, strength and aesthetic potential of fired clay bricks:

- Solid bricks provide high compressive strength up to 100 MPa. Perforated bricks strike a balance with strength and weight reduction.

- Mortar bonds the masonry units together and transfers loads between them. Lime mortar and cement-sand mortar are commonly used.

- Mortar joints are the weakest link – quality workmanship is vital to keep joint thickness limited to 10 mm.

- Reinforced brick masonry has steel rebars and ties to improve tensile and shear strength. Grouted cells provide additional reinforcement.

- Corbelling can judiciously support slab projections from loadbearing brick walls in small structures.

- Brick veneer masonry has a single wythe of external brick covering a concrete or framing backup. Anchors connect the two leaves.

Brick masonry has superior natural appearance but needs protection from weathering and leakage through joints.

Mortar for Masonry Walls

Mortar bonds masonry units together, seals against water infiltration, and provides load transfer between units through joints. Desired mortar properties:

- Workability to permit laying of masonry units easily with proper joint filling

- Bond strength to transfer stresses between units without separating

- Compressive strength lower than masonry units to control crack locations

- Consistent water retention without bleeding or drying too quickly

- Durability against weathering agents and environmental conditions

Mortar is specified by type per ASTM C270 which defines composition and properties. Type N is commonly used with minimum compressive strength of 5 MPa. Mix proportions are 1:1:6 (cement:lime:sand) for Type N.

Masonry Wall Foundations

Masonry walls transmit heavy self-weight and superstructure loads to the supporting foundation. Key foundation design aspects are:

- Check bearing capacity of soil to limit footing pressures within allowable limits.

- Isolated spread footings under walls are preferable to control differential settlements.

- Step foundations in slope areas. Extend footings below frost level.

- Provide damp-proof course atop foundation to prevent moisture ingress.

- Footings must be level, monolithic and free of soft spots for proper support.

- Foundation walls may be concrete or masonry. Limit height and thickness ratios to ensure adequate stability.

- Weep holes in exterior foundation walls drain water and reduce hydrostatic pressure behind walls.

Proper foundation design and construction prevents common issues like settlement and cracking in masonry walls.

Masonry Retaining Walls

Retaining walls sustain significant lateral soil pressures. Masonry walls are well suited as retaining walls owing to their mass and inherent high compressive strength. Design aspects include:

- Check overturning and sliding stability using large base widths or counterforts.

- Weep holes relieve hydrostatic pressure buildup behind walls. Include drain rock backfill.

- Include expansion joints at regular intervals to accommodate movements and prevent cracks.

- For high walls over 2m, use reinforced masonry or concrete stem walls with masonry veneer.

- Limit height to thickness ratios to 6 for unrestrained masonry walls. Include pilasters for taller walls.

- At the top, use coping, cap stones or masonry parapets properly integrated with the wall.

With good drainage and design, masonry retaining walls can perform for decades even in harsh environments.

Masonry Wall Specifications

Masonry construction must comply with accepted building codes and ASTM standards to ensure proper quality levels. Some key specifications per ASTM C90 include:

Masonry Units

- Maximum 5% broken or damaged units

- Minimum thickness of 10 cm for concrete blocks

- Nominal modular size and dimensions within 4 mm tolerance

- Absorption limits – less than 12% for clay bricks

Mortar

- Mortar types and mixes conforming to ASTM C270

- Preparation per ASTM C780 procedures

- Placement within 2.5 hours of initial mixing

- Consistent workability without retempering

Masonry Construction

- Bonds: Running, stack, English – as per structural design

- Joints: 10-12 mm thickness, fully filled

- Plumb and level masonry courses, pattern and finish

- Bracing as needed till cured

- Protect freshly laid masonry from weathering

Compliance with such industry specifications ensures good workmanship and durable, high quality masonry walls.

Bonds in Masonry Walls

The pattern in which masonry units are laid is known as the bond. Different bonds impart unique structural and aesthetic properties. Common bonds include:

- Running bond – Most of the vertical head joints are continuous. Maximum continuity and strength.

- Stack bond – Vertical head joints aligned in columns. Used for thinner walls using half-units.

- English bond – Alternate courses are composed of headers and stretchers. Provides good transverse strength.

- Flemish bond – Each course has alternating headers and stretchers. Attractive pattern.

- Herringbone bond – Headers form a zigzag pattern. Resists diagonal cracking but complicated to construct.

The bond pattern influences structural stability, aesthetics, construction ease and cost. Running bond is the simplest and strongest. Stack bonding requires thin walls and is less stable. Flemish and English bonds provide a good balance. Herringbone is less common owing to complexity but has visual interest. The structural engineer and mason collaborate to select an appropriate bond for each masonry wall application.

Conclusion

Masonry walls have stood the test of time owing to their strength, durability, fire protection, and aesthetics. However, proper structural design, materials selection, construction practices and quality control are needed to build robust masonry structures.

Understanding the various types of masonry units and bonds, reinforcement strategies, critical construction details, and relevant codes and standards enables architectural and structural engineers to effectively tap into the benefits of masonry construction.

Using the principles and best practices outlined here, safe and durable masonry structures can be successfully built.