When it comes to constructing a durable and long-lasting concrete slab, one crucial factor to consider is the minimum thickness.

The thickness of a concrete slab plays a vital role in its ability to withstand loads, prevent cracking, and provide a stable foundation for your project.

Whether you’re pouring a slab for a residential patio or a commercial warehouse, ensuring the proper minimum thickness is essential.

In this blog post, we’ll delve into the factors that determine the appropriate minimum thickness for concrete slabs and discuss why adhering to these guidelines is crucial for the success of your project.

Minimum Thickness of Concrete Slab for Sheds – Meeting IS Code Requirements

When constructing a shed, it’s essential to ensure that the concrete slab foundation meets the minimum thickness requirements set by the Indian Standard (IS) Code. According to IS 456:2000, the minimum thickness of a concrete slab for a shed should be at least 100mm (4 inches).

This thickness ensures that the slab can withstand the loads of the shed structure and any stored materials.

Additionally, the slab should be reinforced with steel reinforcement bars to improve its strength and durability. Adhering to these IS Code guidelines will help you build a stable and long-lasting foundation for your shed.

Understanding the Minimum Thickness of Concrete Slab on Grade

When constructing a concrete slab on grade, it’s crucial to get the minimum thickness right. The thickness of the slab depends on various factors, such as the intended use, load requirements, and soil conditions.

According to the American Concrete Institute (ACI), the minimum thickness for a residential concrete slab on grade is typically 4 inches (100mm). However, for heavy-duty applications like garages or industrial floors, the minimum thickness may increase to 5-6 inches (125-150mm).

It’s essential to consult with a professional engineer to determine the appropriate thickness for your specific project, ensuring a durable and long-lasting concrete slab on grade.

The Importance of Minimum Thickness in Reinforced Concrete Slabs

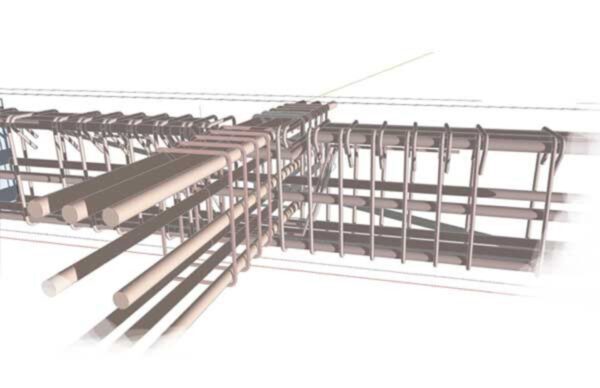

Reinforced concrete slabs are a common structural element in buildings, and their minimum thickness plays a crucial role in ensuring strength, durability, and safety. The thickness of a reinforced concrete slab is determined by various factors, including the span length, loading conditions, and the size and spacing of reinforcement bars.

According to the American Concrete Institute (ACI) 318 Building Code, the minimum thickness of a reinforced concrete slab should be at least 4 inches (100mm) for slabs supported by beams or walls, and 5 inches (125mm) for slabs directly supported by the ground.

Adhering to these minimum thickness requirements ensures that the slab can effectively distribute loads and prevent excessive deflection or cracking, ultimately contributing to the overall structural integrity of the building.

Minimum Thickness of Suspended Concrete Slabs: IS and ACI Code Requirements

When designing and constructing suspended concrete slabs, it’s essential to adhere to the minimum thickness requirements set by the Indian Standard (IS) and American Concrete Institute (ACI) codes.

According to IS 456:2000, the minimum thickness of a suspended reinforced concrete slab should be 125mm (5 inches) for spans up to 3.5 meters, and 150mm (6 inches) for spans between 3.5 and 5.5 meters.

Similarly, ACI 318 Building Code stipulates a minimum thickness of 5 inches (127mm) for slabs supported by beams or walls, with additional thickness required for longer spans or heavier loads.

Complying with these code requirements ensures that the suspended concrete slab has sufficient strength, stiffness, and durability to withstand the imposed loads and prevent excessive deflection or cracking, ultimately providing a safe and stable structure.

Minimum Thickness of Concrete Paving Slabs: ACI Code Guidelines

When it comes to installing concrete paving slabs, the American Concrete Institute (ACI) provides guidelines for minimum thickness to ensure durability and long-term performance.

According to ACI 330R-08, the minimum thickness of concrete paving slabs depends on the intended use and the expected traffic loads.

For pedestrian walkways and patios, the minimum thickness should be 4 inches (100mm), while for driveways and parking areas with light vehicular traffic, a minimum thickness of 5 inches (125mm) is required.

For heavy-duty applications like industrial pavements or loading docks, the minimum thickness increases to 6-8 inches (150-200mm).

By adhering to these ACI code guidelines, you can ensure that your concrete paving slabs have the necessary strength and resilience to withstand the anticipated loads and provide a lasting, stable surface for years to come.

Ensuring Durability: Minimum Thickness of Concrete Topping Slabs

Concrete topping slabs are commonly used to resurface existing concrete floors or to provide a fresh, durable surface for new construction.

To ensure the longevity and performance of these slabs, it’s crucial to adhere to the recommended minimum thickness.

According to industry standards, the minimum thickness for a concrete topping slab should be at least 1 inch (25mm) for bonded overlays and 2 inches (50mm) for unbonded overlays.

However, for areas subjected to heavy traffic or high impact loads, such as industrial facilities or commercial kitchens, the minimum thickness should be increased to 3-4 inches (75-100mm).

By maintaining these minimum thicknesses, you can ensure that your concrete topping slab has sufficient strength, durability, and resistance to cracking or delamination, ultimately providing a reliable and long-lasting surface for your project.