Slab thickness design is a critical component in the construction of industrial concrete floors, as it directly influences the floor’s ability to withstand the heavy loads and intense traffic commonly found in industrial settings.

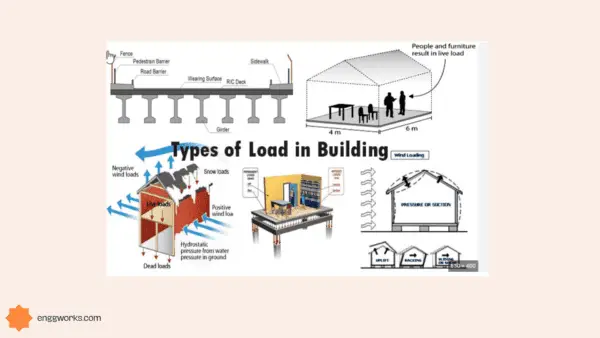

The process of determining the appropriate slab thickness involves a thorough analysis of various factors, such as the anticipated live and dead loads, the subgrade’s bearing capacity, and the concrete’s mechanical properties.

Additionally, the type and amount of reinforcement used in the slab, as well as the presence of joints and other structural elements, must be considered when designing the slab thickness.

Proper design not only enhances the floor’s durability and performance but also helps to minimize the risk of costly failures and repairs over its lifespan.

Slab thickness design for industrial concrete floors on grade according to IS Code

When designing industrial concrete floors on grade, one of the most important considerations is the slab thickness. The Indian Standard IS 15658:2006, “Precast Concrete Blocks for Paving,” provides guidance on determining the appropriate slab thickness based on the expected traffic loads and subgrade conditions.

According to IS 15658:2006, the minimum recommended slab thickness for industrial concrete floors on grade is 150 mm (approximately 6 inches). However, this thickness may need to be increased depending on the specific requirements of the project.

For example, let’s consider an industrial warehouse floor that will be subjected to heavy forklift traffic and occasional storage of heavy machinery. In this case, the designer may opt for a slab thickness of 200 mm (approximately 8 inches) to ensure that the floor can withstand the anticipated loads without cracking or failing.

To determine the optimal slab thickness, designers must also consider factors such as the subgrade’s bearing capacity, the concrete’s compressive strength, and the type and amount of reinforcement used in the slab. By carefully evaluating these factors and following the guidelines set forth in IS 15658:2006, designers can create industrial concrete floors on grade that are durable, long-lasting, and able to withstand the rigors of industrial use.

Design slab on grade for heavy loads

When designing a slab on grade for heavy loads, it’s crucial to ensure that the slab thickness and reinforcement are adequate to withstand the anticipated stresses. One common example of a heavy-load application is a warehouse floor that will support large forklifts and heavy storage racks.

To design a slab for this scenario, the first step is to determine the maximum loads that the floor will experience. This includes the weight of the forklifts, the fully loaded storage racks, and any other equipment or materials that will be present. The subgrade’s bearing capacity must also be evaluated to ensure that it can support the slab and the applied loads.

Based on these factors, the designer can calculate the required slab thickness using established methods such as the Portland Cement Association’s (PCA) design procedure. For a warehouse with heavy forklift traffic and storage loads, a typical slab thickness might be 200 mm to 250 mm (8 to 10 inches), with reinforcement provided by steel bars or welded wire mesh.

In addition to the slab thickness, the designer must also consider joint placement and load transfer devices to control cracking and ensure that the slab performs as intended. By carefully evaluating the specific requirements of the project and following established design guidelines, designers can create slabs on grade that are capable of withstanding even the heaviest loads.

Slab thickness for commercial buildings

When it comes to designing slabs for commercial buildings, getting the thickness right is essential for ensuring the structure’s integrity, safety, and longevity. The appropriate slab thickness depends on several factors, such as the anticipated loads, the span between supports, and the concrete’s strength.

For example, consider a multi-story office building with a typical floor plan. The slab thickness for this type of structure might range from 150 mm to 200 mm (6 to 8 inches), depending on the span between columns and the expected live loads, such as office furniture, equipment, and occupants.

In addition to the slab thickness, designers must also consider the placement of reinforcement, which helps to distribute loads and control cracking. The type and amount of reinforcement required will depend on the slab’s thickness, the anticipated loads, and the building’s overall design.