Joints are a critical component in concrete construction.

They are placed at regular intervals in concrete slabs and pavements to help control cracking.

Understanding joints in concrete construction is essential for high-quality, durable concrete structures.

Whether you’re working on a residential foundation, an industrial floor, or a bridge deck, the placement and type of concrete joints you use determine the longevity and crack resistance of your project.

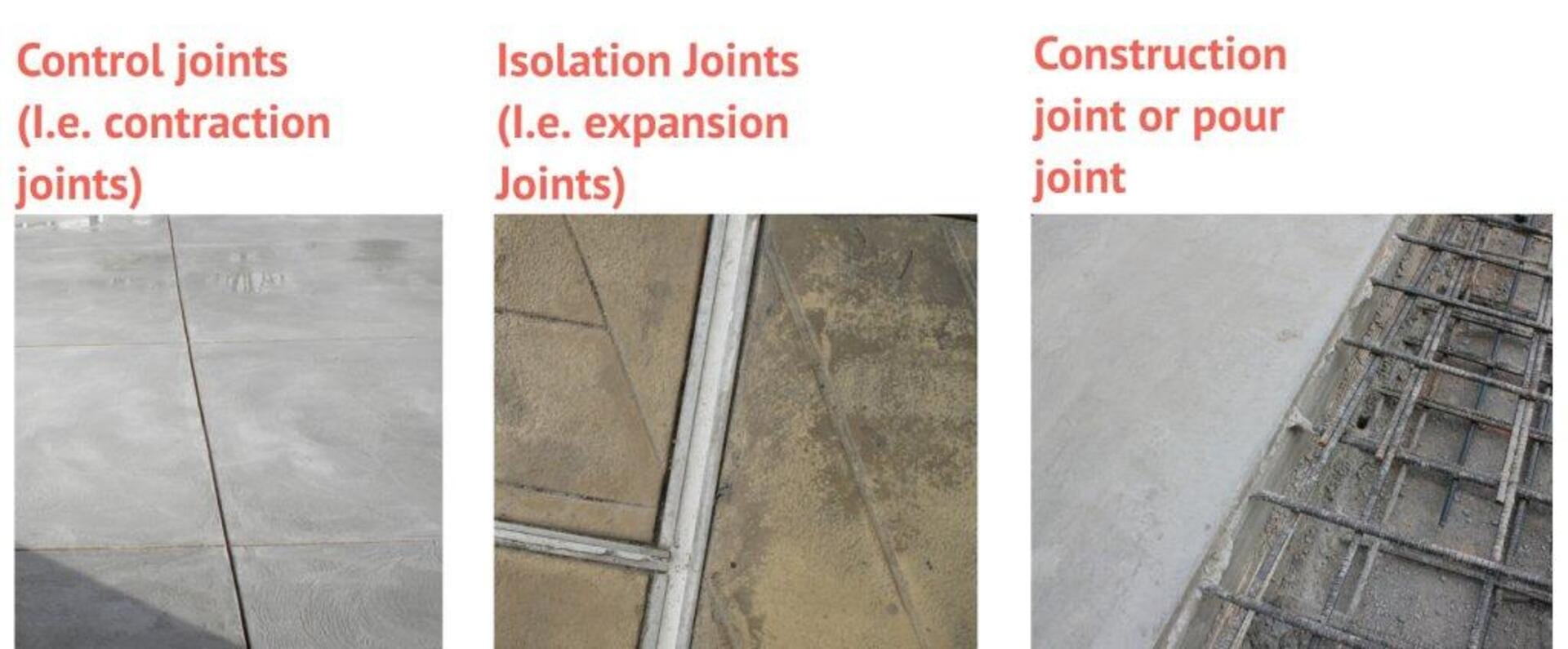

There are four main types of joints used: construction joints, expansion joints, contraction joints, and isolation joints.

- Construction joints allow the concrete to be poured in stages while still allowing for movement and transfer of stresses between sections.

- Expansion joints help concrete expand and contract due to temperature changes and shrinkage.

- Contraction joints are sawed or tooled vertical grooves that regulate where cracks will form as the concrete shrinks.

- Isolation joints completely separate the slab from adjacent walls, columns, or pipes, preventing restraint forces when the concrete and subgrade move differently.

Proper joint design, spacing, load transfer capability, and sealing are essential to allow movement while minimizing cracks.

Key factors include joint depth, materials, configuration, and location. Understanding the purpose and function of each joint type allows civil engineers to design long-lasting concrete structures.

Proper joints control cracks, preventing surface defects, infiltration issues, and pavement failures.

The blog post will provide an overview of joints in concrete construction for civil engineers, contractors, and construction quality managers.

It covers the four main joint types and considerations for effective joint design and construction.

What is a concrete joint?

A concrete joint is a planned point of separation or discontinuity purposely placed within or between concrete structural elements. Joints serve several vital roles:

- Allow movement from expansion/contraction without random cracking

- Distribute stresses and loads across concrete components

- Provide construction interfaces between successive concrete pours

The key to durable concrete depends heavily on the appropriate use of joints throughout the structure.

Why Concrete Joints Matter

Without sufficient joints in desired locations, concrete slabs, walls, and elements would develop extensive random cracking and damage from movement stresses over time. Proper joints circumvent common issues like

- Random uncontrolled cracking from shrinkage

- Edge curling failure along slabs

- Compromised structural capacity

- Water intrusion deterioration

- Uneven joints spalling and faulting

- Shortened concrete lifespan

For quality, durability, and longevity—joints are invaluable.

Why Are Construction Joints Important?

- Enable manageable, staged casting for large concrete elements

- Allow concrete to cope with volume changes due to drying, shrinkage, and temperature variation

- Transfer structural loads safely between adjacent sections

- Prevent uncontrolled cracking and structural weakness

Types of Joints in Construction

Concrete is prone to cracking as it hardens and changes temperature. That’s why there are several types of joints in construction, each with a distinct function:

| Type | Purpose |

|---|---|

| Construction Joint | Interface between concrete poured at different times |

| Contraction Joint | Also called control joint; creates a pre-determined crack location |

| Expansion Joint | Allows movement due to thermal expansion/contraction |

| Isolation Joint | Separates slabs/structures to allow independent movement |

The three main types of concrete joints are

- Construction joints

- Contraction joints

- Expansion/isolation joints

Construction Joints in Concrete: Details and Placement

- Usually vertical, but can be horizontal or inclined, depending on slab geometry

- Must allow horizontal movement perpendicular to the joint due to shrinkage or temperature variations, but prevent vertical or rotational movement that could cause uneven settlement

- Commonly reinforced with smooth rebars or dowels (e.g., a smooth rebar joint used for concrete slab) to allow movement while keeping the slabs aligned and sharing loads

Key Types of Construction Joints in Concrete:

- Butt-Type Joints: Simple abutment of fresh concrete to already-hardened concrete, often for slabs with light loads

- Keyed Joints: Interlocking sections (grooves and tongues) increase load transfer capacity

- Dowel Joints: Smooth steel dowels at intervals across the joint permit movement and improve load transfer (commonly in slabs)

- Groove Joints: Created with tools or inserts, ensuring controlled cracking and better integrity

Construction Joint in Slab: Why It Matters

A construction joint in slab construction is vital when the slab is too large for a single pour or when pouring must stop and start due to scheduling or practical reasons. Properly implemented, these joints:

- Maintain slab alignment

- Manage cracks and stresses

- Distribute loads uniformly across the slab

Smooth dowels and rebars are often embedded across these joints to provide strength while allowing minor horizontal movement—a key feature in concrete joints.

Types of Concrete Joints: In Depth

Let’s compare the main types:

- Construction Joint: For staged pours; reinforced for load transfer; designed for long-term stability.

- Contraction Joint: Cut or formed grooves that manage shrinkage cracks by making the concrete weaker along specific lines.

- Expansion Joint: Full-depth separation, filled with compressible material, accommodates thermal expansion.

- Isolation Joint: Full separation between slab and adjacent structure (wall, column) allows independent movement.

Construction Joint vs Contraction Joint

- Construction Joint: Where two different batches of concrete meet; must ensure continuity and structural performance.

- Contraction Joint: An intentionally weak line (sawed or tooled) so cracks develop along it, not randomly.

Summary: Construction joints connect pours; contraction joints control cracks from shrinkage.

Isolation Joint vs Expansion Joint

- Isolation joint: Separates slabs from fixed elements, allowing three-dimensional movement and preventing transfer of stress to adjacent structures

- Expansion joint: Primarily allows movement from temperature changes and is often broader with compressible filler material

Best Practice Tips for Construction Joints in Concrete

- Plan joint locations in advance, considering structural layout and pour schedules

- Reinforce joints with smooth rebars or dowels to allow movement while transferring shear

- Use keyed or groove joints for added mechanical interlock if needed

- Seal joints properly to prevent water ingress or corrosion

- In floors and slabs, align joints with changes in geometry, columns, or movement risk areas

Types of Joints in Concrete Construction

There are several categories and subtypes of joints employed in concrete construction for specific applications:

Contraction/Control Joints

Contraction joints relieve internal shrinkage stresses. Common examples:

- Saw Cut Joint—early concrete cutting to control crack location

- Grooved Joint—tool-pressed line before curing

- Formed Joint—An interim wood/metal strip forms continuous gap

Construction Joints

Construction joints provide an interface between successive concrete placements:

- Cold Joint—between hardened and fresh concrete pours

- Keyed Joint—roughened edge for next pour

- Doweled Joint—rebar/dowels link pours

Isolation Joints

Isolation joints completely separate slabs/structures, allowing individual movement. Types include:

- Expansion Joints—allow expansion/contraction

- Seismic Joints—accommodate seismic displacements

- Settlement Joints—allow structure settlement

Load Transfer Joints

Load transfer joints use dowels/rebar to transmit loads across separations:

- Doweled Joint—Smooth dowels connect but allow horizontal movement

- Bonded Joint—grout bonds rebar/dowel across joint

The appropriate selection and construction of these integral joints fosters resilient concrete structures.

Where and When Should Joints Occur?

Joint placement follows certain guidelines based on the type:

Contraction Joints

Contraction joint spacing typically falls between 2 and 3 times the slab thickness. Maximum spacings:

- Sidewalks—5 to 8 ft o.c.

- Driveways—8 to 12 ft o.c.

- Structural slabs—15 ft o.c.

Ideally contraction joints are installed early before uncontrolled cracking begins.

Construction Joints

Construct stops and new starts as close as possible to intended specified locations. Stagger adjacent floor-level joints.

Isolation Joints

Occur where slabs contact fixed items like foundations or columns or at slab intersections. Install on all slab perimeter edges.

In general, lay out more joints rather than less. Consult concrete specialists to confirm layouts.

Poured Concrete Joints vs Saw Cutting

While saw-cutting concrete early on creates joints, planning ahead allows placing joints before pouring for better control.

Poured-in-Place Joints

- Form directly in wet concrete

- Materials like foam boards easily shape joints.

- No special tools needed

- Risk of edge raveling or spalling

Saw-Cut Joints

- Cut into hardened concrete with specialty saw

- Precision automated machines make clean cuts

- Enables custom layout adjustments

- More time- and skill-dependent

Both methods play an important role across applications. Saw cutting shines for intricacy, while formed joints simplify large pours.

Recommended Materials for Concrete Joints

Recommended joint materials include:

Contraction Joints

- Preformed foam strips

- Fiberboard strip with removable top cap

- Flexible rubber or PVC waterstops

Construction Joints

- Smooth epoxy-coated steel dowel bars

- Keyed formboard inserts

- Waterstop membranes/sealants

Isolation Joints

- Preformed expansion joint filler

- Compressible foam tubes

- Flexible elastomeric sealants

- Backer rods

Usage depends on movement capacities, concrete element types, and joint orientations. Custom combinations cater to unique project conditions.

Sealing Concrete Joints

While joint materials fill open gaps, sealants protect joints from water, grit, and incompressibles that lead to replacements.

For best sealant adhesion:

- Clean joint walls thoroughly

- Install appropriate backer rod spacer

- Prime surfaces per product instructions

- Apply 1⁄4”–1⁄2” sealant thickness

- Tool sealant profile smooth

Common plasticizing sealants:

- Polyurethane

- Vulkem polyurethane

- Self-leveling polyurea

- Premium-grade silicone

Sealing execution and resealing timeframe maintenance protects joint waterproofing integrity.

Cutting Control Joints in Concrete

In the early stage, cutting was done strategically to create weaker planes before the concrete dried and cracked unpredictably. Essential tips:

Proper Timing

Cut as soon as concrete can bear weight without raveling—1 to 4 hours after pouring. Earlier is better.

Saw Selection

Use dry cutting saws without water to prevent weakening concrete through increased water/cement ratios.

Controlled Cuts

Make smooth, steady cuts without sudden corner turns to prevent blowout chips and facilitate sealing later on.

Joint Layouts

Reference pre-approved drawings with measured grids for cut locations. Mark measured guides on the slab.

Careful control joint planning and execution prevents unsightly random cracks.

Fibreboard for Quality Expansion Joints

Fiber-reinforced expansion joint filler offers many performance advantages:

⚙️ Interlocking—Tongue and groove edges provide continuous expansion gap coverage.

🔩 Tough Fastening—Composite fiber holder pins anchor vertical orientation filler against concrete pressure.

💧 Water Resistant—Impervious hardened material resists deterioration from wet job site conditions.

🛠️ Easy Install—Lightweight, pliable sheets speed construction versus metal plates while absorbing vibration.

Certified fiber-composite joint fillers deliver consistent quality across roles.

Load Transfer Steel for Jointed Concrete

While joints allow necessary movement, steel reinforcement transfers tension and compression loads across the void to preserve structural integrity.

Dowel Bars

Smooth, galvanized steel pins allow horizontal slab movement while bearing shear forces.

Deformed Rebar

Bonding mortar locks deformed steel reinforcing bars in place across separation gaps.

Shear load transferring steel placed per engineering recommendations prevents joints from working themselves apart over heavy use.

Protecting Fresh Concrete Joints

Preserving newly created joints ensures properly functioning performance down the road. Best practices include:

⛔️ No Traffic—Avoid walking on joints until concrete adequately cures to prevent edge damage

🔒 Secure Forms—Firmly stake void forms/boards against floating or dislodging from poured concrete placement

💧 Moisture Retention—Mist cure flatwork with water spray without destroying fresh joints

🛣️ Overlay Alignment—Ensure accurate joint alignment with rebar, waterstops and formwork for continuity in floor topping slabs poured over joints

Proactive protection reduces joint deterioration risks before sealants fill the created gaps.

FAQ Highlights

What is a construction joint in concrete?

A construction joint is the meeting point between two separate concrete pours, deliberately formed to enable staged construction while maintaining structural continuity.

What are the types of construction joints in concrete slabs?

Common types include butt-type, keyed, doweled, and groove joints—each suited for specific structural needs.

What’s the difference between a contraction joint and a construction joint?

Construction joints join pours; contraction joints (control joints) predetermine where shrinkage cracks will form.

Where are construction joints placed in a slab?

Construction joints are typically placed at column centers, at changes in slab geometry, and at locations where daily pours must be stopped; it is essential to always follow the structural plan for heavy equipment or load locations.

What are the most important concrete joint types for durability?

Construction, contraction, expansion, and isolation joints all play vital roles; the best choice depends on your structural and environmental conditions.

Conclusion

Specifying, locating, and installing appropriate structural movement joints delivers concrete longevity and averts extensive repairs down the road.

What may seem like subtle upfront considerations carrying short-term costs and construction involvement can prevent massively expensive maintenance, tear-out projects, or safety issues associated with uncontrolled concrete cracking years later.

Work closely with structural engineers and reputable contractors to get durable, low-maintenance concrete joints right from day one. The value earned over decades of service makes that involvement well worth it.