Honeycombing in concrete represents one of the most detrimental defects in concrete construction, significantly compromising integrity. This phenomenon occurs when gaps and cavities resembling a honeycomb pattern are left behind in cured concrete.

Instead of a continuous matrix, concrete contains weaknesses in the form of hollow pores and channels that permeate within.

Honeycombing stems largely from inadequate pouring and consolidation of the wet concrete mix during placement. The subsequent hardening traps these voids internally, severely reducing strength, increasing permeability, and enabling eventual steel corrosion.

Repairing honeycombed concrete proves extremely difficult and expensive once . Making stringent preventative measures imperative for avoiding catastrophic future failures or premature deterioration.

Formal specifications classify honeycomb severity. ACI 117 defines “minor” honeycombing as gaps less than 15mm deep occupying less than 3% surface area. Otherwise honeycombing gets classified as “major”.

What is Concrete Honeycombing?

Concrete honeycombing refers to large voids and cavities left in concrete structures resembling a honeycomb shape.

It occurs when concrete fails to adequately fill the framework formwork, creating gaps that weaken structural integrity once the forms are removed.

These unplanned pores and air holes in the concrete reduce strength and durability while allowing increased water penetration, chemical corrosion, and debris accumulation internal to the structure. Honeycombs pose severe quality defects.

Causes of Concrete Honeycombing

Common root causes lead to defective honeycombed concrete:

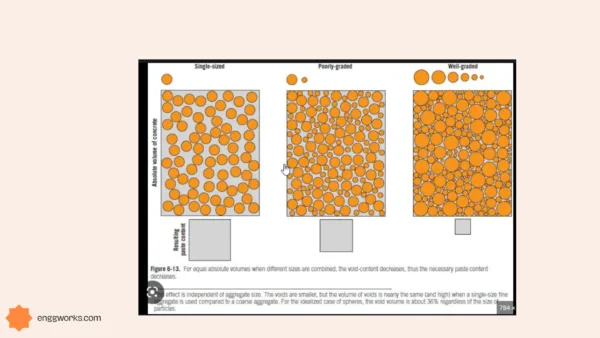

- Improper concrete mix design lacking sufficient fines and paste

- Inadequate vibration of wet concrete when pouring – entrapped air gets trapped

- Too narrow concrete member dimensions restrict flow and consolidation

- Overly congested reinforcement spacing impedes concrete flow

- Faster setting time doesn’t allow proper flow and placement

Catching and addressing such issues early on prevents honeycomb formation.

Types of Honeycombing in Concrete

Honeycombs have different natures based on shape and size:

- Surface honeycombing occurs as small shallow cavities near the structural skin.

- Larger, deeper internal honeycombs span into structural depth.

- Columnar voids create lineal hole channels along pouring pathways.

Concrete Honeycomb Repair Procedure

The key concrete honeycomb repair procedure includes:

- Inspection and Damage Assessment

- Visually inspect honeycombed areas after removing forms

- Tap concrete with hammer for hollow sound identification

- Classify damage level (minor or major)

- Damage Removal and Prep

- Chip away all loose or cracked concrete with a hammer or chisel to sound concrete base

- Saw cut edges perpendicular for structural Uniformity

- Clean repair zone thoroughly – no loose particles

- Repair Method Selection

- Surface honeycombing – patch small holes with cement mortar

- Deep honeycombs – inject low-viscosity epoxy grout resins

- Columnar voids – pressure inject sealants through drilled ports

- Install Repair Material

- Apply concrete bonding agent to open pores and cavities

- Fill/inject selected cementitious grout, epoxy, or sealant material

- Finishing and Curing

- Screed/trowel cementitious patches flush with surrounding surface

- Allow thorough curing as per product specifications

- Seal exterior repairs with protective coatings

Following manufacturer procedures is critical for product performance. Quality inspection also ensures repairs address all honeycombing adequately.

Preventing methods of Honeycombing in Concrete

Here are the key methods to prevent honeycombing in concrete:

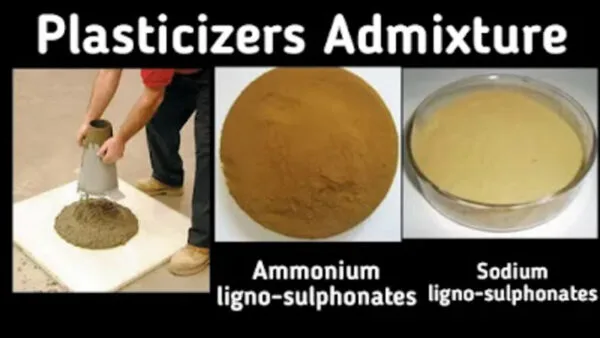

- Proper Concrete Mix Design

- Optimize aggregate gradation, paste volume, and fines content for flowability

- Adjust water, air entrainers, plasticizers/superplasticizers

- Ensure adequate workability retention during pour

- Planning Pour Rates and Sequences

- Schedule sequences to ensure lifts join while still plastic

- Regulate pour rate to placement capacity for even flow/spread

- Quality Formwork

- Densely brace forms and liners to resist deformation

- Seal joints and punctures to prevent leakage

- Adequate Vibration and Consolidation

- Vibrate with suitable amplitude for member size and reinforcement

- Systematically progress vibration points to eliminate air pockets

- Clear Reinforcement Congestion

- Sufficient spacing between rebar and other inserts

- Continual Quality Control Checks

- Assess consistency and adequate fill during progress via visual, hammer sounding, probing etc.

Careful attention and proactive adjustments in these areas prevents honeycomb-inducing defects.

Testing Concrete for Honeycombing

Inspection methods to detect honeycombs include:

- Visual and sounding checks on surface after form removal

- Test coring to extract concrete core samples for examination

- Non-destructive rebound hammer testing for irregular results

- Ultrasonic pulse velocity tests to identify subsurface defects

Strength Impacts

some key points on the strength impacts of honeycombing defects in concrete:

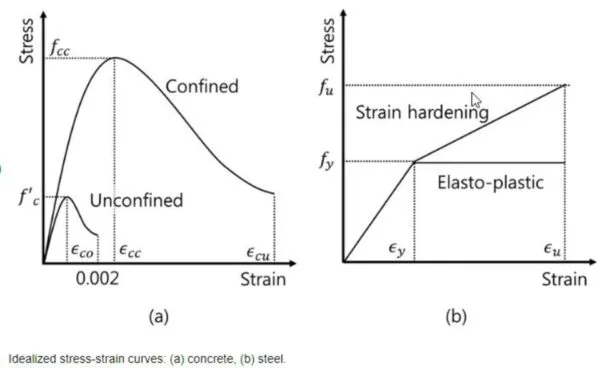

- Honeycombed concrete can lose 25% to 75% of its intended design strength due to the internal voids and gaps created.

- The numerous pores significantly reduce the cross-sectional area able to resist structural loads.

- It causes discontinuities in concrete member integrity, concentrating stresses unevenly around the cavity peripheries.

- Exposed inner surfaces lead to accelerated erosion, freeze-thaw damage, steel corrosion, and chemical decomposition – further reducing concrete durability over time.

- Strength varies depending on honeycomb sizes and frequency – occasional minor surface honeycombing has less impact compared to widespread major internal honeycombing.

- But even sparse deep honeycombs penetrating over halfway into a member’s thickness can undermine capacity to reinforced layers.

- The porous nature allows easy access for water, oxygen, chlorides and sulfates; fueling steel corrosion or Alkali Silica Reactions which expand cracks.

- Loss of stiffness as well as sheer and tensile capacity limits safe structural performance.

- Compromised structural sections require loading restrictions or remedial strengthening to supplement repairs.

Repairing Honeycomb Concrete Columns

Column repairs follow typical honeycomb repair methods but also require:

- Temporary supporting braces until full strength restoration

- Depth limits on chipping to avoid buckling threats

- Reinforcing end confinements and lateral ties

- Encasement with reinforced concrete collar overlays

Honeycomb Concrete Slab Repair

Slab repairs utilize slab jacking, epoxy grouts, and re-topping surfaces after chipping. For bigger patches, new structured overslabs get placed over enhanced support beds.

Ramifications

Besides strength impacts, honeycombing causes further problems:

- Exposed endurance and reinforcement corrosion

- Freeze-thaw cracking and chemical leeching

- Noise transmission across acoustical building partitions

- Higher financial costs from rework and structural longevity impacts

Proactive prevention is essential for avoiding honeycomb defects.

Conclusion

The porous honeycombing defect critically impacts concrete strength and structural soundness.

Engineers must emphasize stringent quality practices focused on adequate pour procedures, vibration, and mix workability to limit risks of unstable voids forming.

Essentially, unchecked honeycombing defects present both immediate and time-dependent strength risks that can lead to eventual instability or collapse.

Repairing honeycombs is tedious – proving far easier to prevent them outright through comprehensive structural process controls.