Concrete is one of the most widely used building materials for construction projects. Its versatility, durability and strength make it an ideal choice for everything from home foundations to large commercial buildings. A key factor in achieving quality concrete is using the proper concrete mix ratio. This refers to the ratio of cement, sand, and aggregate used to create the concrete mixture.

Getting the concrete mix ratio right is crucial for meeting the required strength and workability needed for the project. This article provides a comprehensive guide on concrete mix ratios, including the different types of mixes, standard ratios, and factors that impact the ideal ratio.

What is Concrete Mix Ratio?

The concrete mix ratio refers to the ratio of cement, sand, and aggregate used to make concrete. It is the combination of these ingredients that gives concrete its unique properties.

Cement acts as the binding agent or glue that holds the mixture together when mixed with water.

Sand provides workability and uniform particle size to concrete.

Aggregates like gravel and crushed stone give the mixture volume and dimensional stability.

The proportions of these ingredients determines the concrete’s strength, durability, and water resistance. Concrete mix ratios are often specified based on the type of construction project and conditions the concrete will be exposed to.

Types of Concrete Mix Ratios

There are two main types of concrete mix ratios:

Nominal Mix Ratios

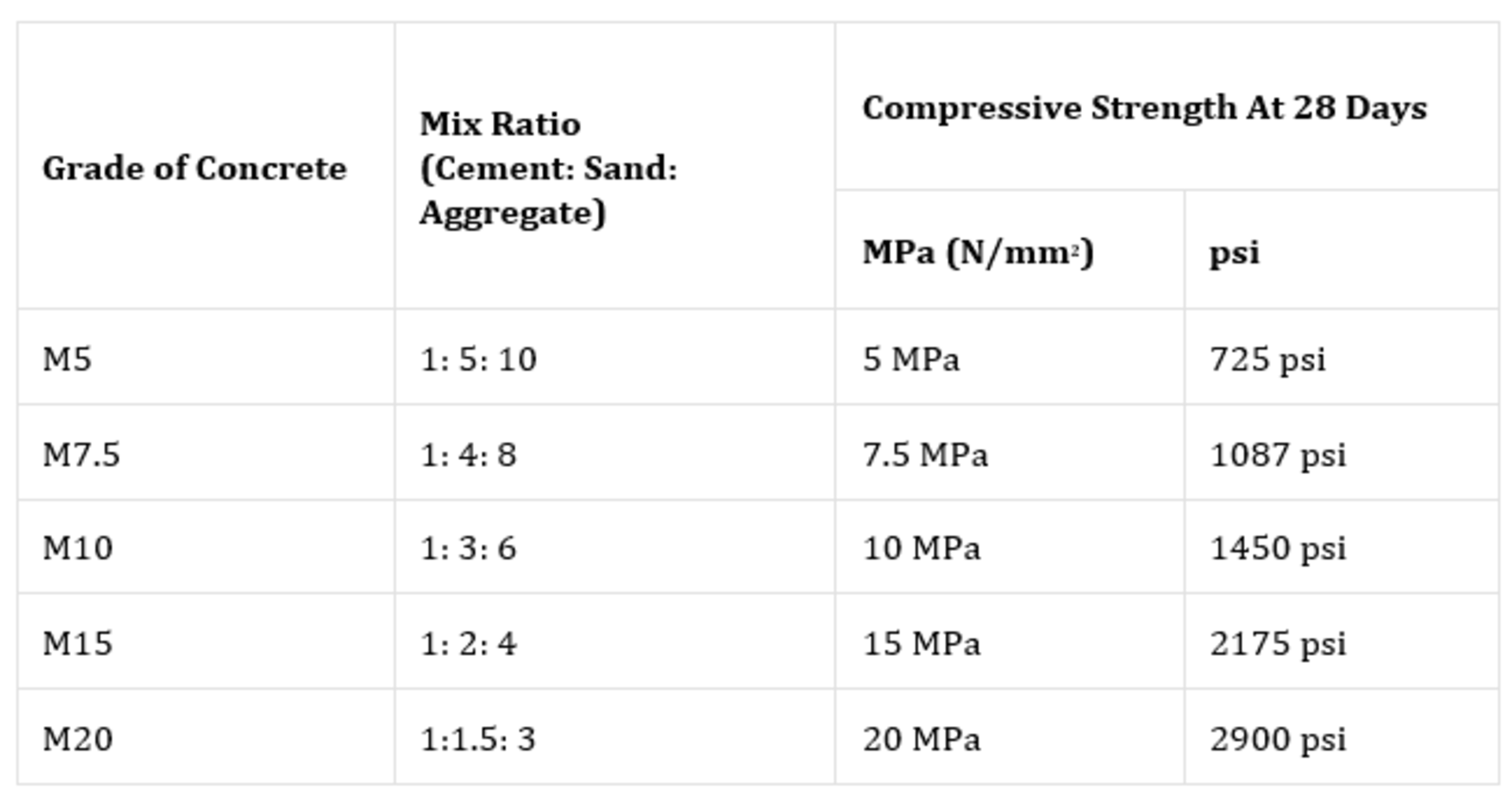

in nominal mix ratio the quantity of cement, sand and aggregate are fixed. Nominal mix ratios prescribe concrete mixes by volume using standard shovel or bucket sizes. Common nominal mixes are:

- M15 (1:2:4 ) – This mix has 1 part cement, 2 parts sand, and 4 parts aggregate. It results in an approximately 2175 psi concrete used for standard construction projects.

- M20(1:1.5:3) – This nominal mix ratio contains more cement and is stronger, with a psi around 3000. It’s suitable for more demanding applications.

- M25(1:1:2) – This ratio yields high strength concrete of 6000 psi and is used in heavy construction projects.

The strength of the nominal mix concrete varies widely for given workability due to variation of mix ratio. M15,M20 are considered as nominal mix of concrete.

Design Mix Ratios

Design mix ratios are calculated based on the desired concrete properties like strength and water content. The proportions are determined using quality controlled materials to optimize performance.

Design mixes allow more control over the concrete characteristics. They require testing samples to verify the proportions meet specifications before use in the field.

Standard Concrete Mix Ratios

nominal mix of fixed ratios show variation in strength resulting in over-rich or poor mix. so minimum compressive strength is assigned in many proportions and termed as standard mix. as per IS 456:2000 M25,M30,M35,M40 are termed as standard mix. some standard mixes for different applications include:

- Foundations – 1:2:4, 4000 psi

- Slabs, driveways – 1:2:3, 3000 – 3500 psi

- Footings – 1:3:6, 2500 – 3000 psi

- Walls – 1:1:2, 6000 psi

- Patios – 1:2:3, 3000 – 3500 psi

- Sidewalks – 1:2:3, 3000 – 3500 psi

These standard ratios provide a starting point based on common uses. The actual mix can be tweaked as needed to achieve the desired concrete properties.

High Strength Concrete Mix Ratios

For applications requiring very durable, high strength concrete, special mix designs are used with higher cement proportions:

- Foundations – 1:1.5:3, 6000 psi

- Bridges, parking garages – 1:1:2, 10,000+ psi

- Marine projects – 1:1.5:3, 6000 – 8000 psi

The extremely high strength mixes have enhanced durability but also higher material costs. They are specified only when needed based on the structural loads and environment.

Factors Affecting Concrete Mix Design

Several factors influence the ideal concrete mix ratio:

- Strength – Higher compressive strength requires more cement, which increases cost. Only add extra cement if needed.

- Workability – More sand provides better workability for placing and finishing concrete. Excess sand reduces strength.

- Water content – More water improves workability but reduces strength. Use the minimum amount needed.

- Durability – Harsher environments call for low water-cement ratios and air entraining agents.

- Aggregate size – Bigger aggregate dimensions reduce shrinkage but can hamper workability.

- Slump – Slump tests measure concrete workability. A high slump allows lowering the water content.

- Exposure – Concrete exposed to freezing, salt or dampness requires higher strength and water resistance.

Proper concrete mix design considers all these factors to find the optimal balance. Testing trial batches helps dial in the right proportions.

Benefits of Using the Right Concrete Mix Ratio

Getting the concrete mix ratio correct provides many benefits on construction projects:

- Ensures concrete meets the required compressive strength specifications

- Provides adequate workability for placing and finishing concrete

- Minimizes shrinkage cracking due to excess water content

- Provides proper water resistance and durability for the environment

- Optimizes the cost by preventing over-use of expensive cement

- Produces quality concrete that lasts for the service life of the structure

In summary, dialing in the right concrete mix ratio is essential for structural integrity, preventing premature failures, and minimizing issues like cracking and crumbling concrete work. With the right mix design, concrete structures will stand the test of time and provide lasting value.

Concrete Mix Ratio Calculator

To take the guesswork out of concrete mix ratios, use a concrete calculator that lets you input the mix attributes and proportions to optimize the design. Online calculators provide guidance on mix ratios for different concrete strength and aggregate sizes.

Mobile apps are also available to easily calculate and adjust concrete mix ratios on the go during construction projects. With the ability to tweak the mix and rerun calculations, concrete contractors can experiment and dial in the optimal concrete ratio.

Key Takeaways on Concrete Mix Ratios

- Concrete mix ratio refers to the ratio of cement, sand, and aggregate in the concrete mixture.

- Nominal and design mix ratios are the two main types of concrete mix ratios.

- Standard mix ratios provide a general guideline for concrete based on common applications.

- Factors like strength, workability, water content, and environment impact the ideal mix ratio.

- Properly designed concrete mix ratios are crucial for achieving the strength, durability and quality needed on construction projects.

Using the right concrete mix ratio ensures you get a workable, strong, and long-lasting concrete mix for your construction project needs.