A plinth beam, also known as a grade beam, is a vital structural component in building construction. It is a horizontal reinforced concrete beam that is cast at the plinth level, which is the junction between the superstructure and the foundation of a building.

As the bedrock of a building’s design, the plinth beam’s strategic placement and meticulous engineering are paramount to ensuring the stability and longevity of the overall construction.

Whether you’re a seasoned professional or an aspiring civil engineer, understanding the nuances of plinth beam design is essential for delivering robust and reliable structures that withstand the test of time.

What is Plinth Beam?

The primary function of a plinth beam is to evenly distribute the load of the superstructure, including walls, columns, and slabs, onto the foundation.

By doing so, it minimizes differential settlement and ensures the stability of the building. Additionally, plinth beams provide a level surface for the construction of the superstructure, making it easier to maintain a consistent floor level throughout the building.

Plinth beams also serve as a barrier against moisture and pests, preventing them from entering the building from the ground level.

By encapsulating the foundation and providing a continuous, solid surface, plinth beams help to protect the building from water damage and insect infestations, thereby enhancing its durability and longevity.

What is Plinth Level?

Plinth level, also known as the plinth course, refers to the topmost level of a building’s foundation or the lowest level of the superstructure. It is the level at which the ground floor of a building begins, and it is usually slightly elevated from the surrounding ground level to prevent water infiltration and provide a clear distinction between the foundation and the superstructure.

The plinth level is an important reference point in construction, as it marks the transition from the substructure to the superstructure. It is typically constructed using reinforced concrete and often includes damp-proofing measures to prevent moisture from seeping into the building. The height of the plinth level can vary depending on factors such as the building’s design, the surrounding terrain, and local building codes and regulations.

Plinth Beam Reinforcement According to IS 13920-2016

Plinth beams are a vital component of a building’s foundation, providing stability and support. The Indian Standard IS 13920-2016 lays down the guidelines for the reinforcement of plinth beams in seismic zones. This code ensures that the beams are designed to withstand the forces generated during an earthquake.

As per IS 13920-2016, the longitudinal reinforcement in plinth beams should consist of at least two bars of 12 mm diameter at the top and bottom. The minimum area of the longitudinal reinforcement should be 0.8% of the gross cross-sectional area of the beam. For example, if a plinth beam has a cross-section of 300 mm x 450 mm, the minimum area of longitudinal reinforcement would be 1080 mm².

Transverse reinforcement, in the form of stirrups, is equally crucial in plinth beams. The code specifies that the stirrups should have a minimum diameter of 8 mm and a maximum spacing of 150 mm. The first stirrup should be placed at 50 mm from the face of the support.

For instance, if a plinth beam has a length of 3 meters, it would require 20 stirrups spaced at 150 mm intervals, with the first stirrup placed at 50 mm from the support.

By following the guidelines set by IS 13920-2016, engineers can design plinth beams that are capable of resisting seismic forces and ensuring the safety of the building and its occupants.

Download plinth beam drawing (Source: bcplonline.co.in)

Plinth Beam Construction Details

The construction of a plinth beam involves several key steps, including excavation, formwork installation, reinforcement placement, concrete pouring, and curing. Civil engineers must pay close attention to these details to ensure that the plinth beam is built to specification and meets all relevant building codes and industry standards.

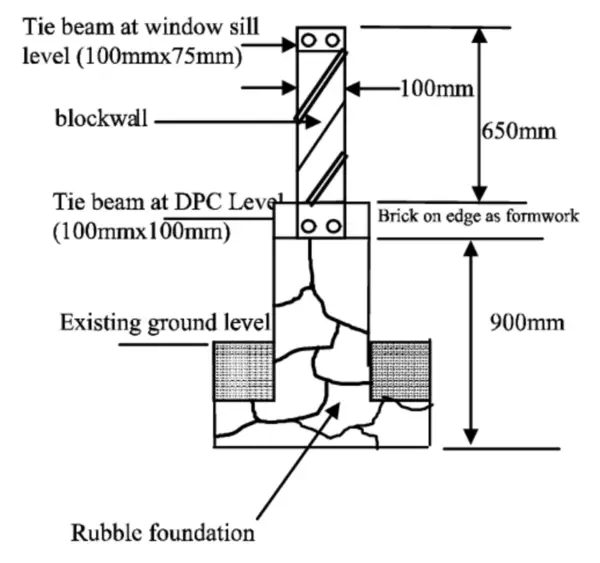

Plinth beam vs Tie beam

| Plinth Beam | Tie Beam |

|---|---|

| 1. Located at the plinth level, which is the junction between the foundation and the superstructure. | 1. Located at the lintel level, which is the top of the door or window frames. |

| 2. Primarily functions to distribute the load of the superstructure evenly onto the foundation. | 2. Primarily functions to distribute the load of the roof or floor slab evenly onto the walls. |

| 3. Runs continuously along the perimeter of the building, connecting the columns and walls. | 3. Runs along the length of the walls, connecting them at the lintel level. |

| 4. Helps to prevent differential settlement and provides stability to the building. | 4. Helps to resist lateral forces and provides stability to the walls. |

| 5. Acts as a barrier against moisture and pests entering the building from the ground level. | 5. Provides a level surface for the construction of the roof or floor slab. |

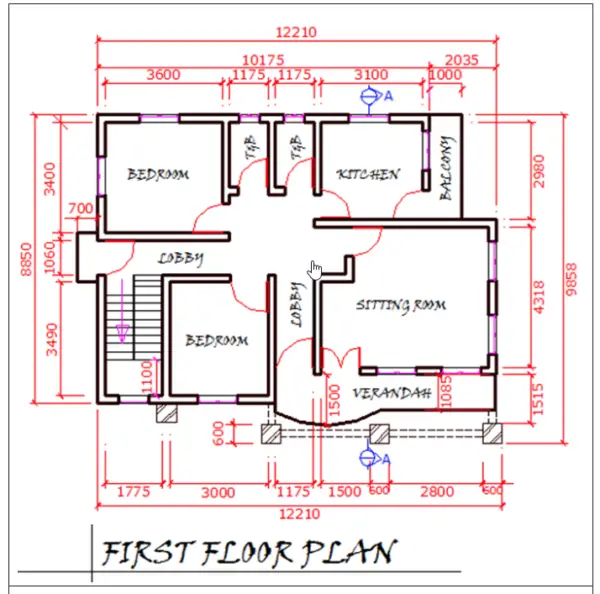

Plinth Beam design for a House

Sizing a plinth beam for a house requires a thorough understanding of the building’s weight, the soil conditions, and the local building code requirements. Civil engineers must use design tables, structural analysis software, and their own expertise to determine the appropriate size and reinforcement of the plinth beam to ensure the stability and safety of the structure.

Plinth Beam Structural Design Guidelines

Plinth beam design is governed by a set of structural design guidelines that cover a wide range of requirements, including material specifications, reinforcement details, minimum dimensions, and installation procedures. Civil engineers must be well-versed in these guidelines to ensure that the plinth beam they design meets all necessary safety and performance criteria.

Minimum Depth of a Plinth Beam Foundation

The minimum depth of a plinth beam foundation is determined by factors such as the soil conditions, the building’s weight, and any local building code requirements. Civil engineers must carefully analyze these factors and use design tables or structural analysis software to determine the minimum depth that will safely support the structure.

Plinth Beam Load Bearing Capacity Considerations

The load-bearing capacity of a plinth beam is a critical factor in the overall foundation design. Civil engineers must carefully calculate the weight of the building, any additional loads, and the soil-bearing capacity to determine the appropriate size and reinforcement of the plinth beam to ensure that it can safely support the structure.

Conclusion:

Plinth beam design is a complex and multifaceted field within civil engineering, requiring a deep understanding of structural principles, soil mechanics, and building code requirements.

By mastering the concepts covered in this article, civil engineering professionals can ensure that the foundations they design and construct are strong, stable, and capable of supporting the structures they are intended to support.

Through careful analysis, precise calculations, and adherence to industry standards and building codes, civil engineers can play a vital role in the development of safe and reliable buildings.