Outrigger structural systems are integral to today’s cloud-piercing skylines, enabling towers to safely rise to elevations once unfathomable.

You can know about outrigger principles, elements and applications explores how these lateral supports uphold the loftiest ambitions of modern architecture.

An outrigger system connects the central core to exterior columns like the stabilizing float on a canoe preventing capsizing.

While deceivingly basic in concept, outrigger integration allows towers to scale over 800 meters relying on this robust technology’s reinforcement.

What is an Outrigger Structural System?

An outrigger system braces high-rise buildings by joining an interior core structure to distant perimeter columns through horizontal cantilevered trusses.

This creates an expanded base framework improving stability and resisting lateral forces from wind or earthquakes.

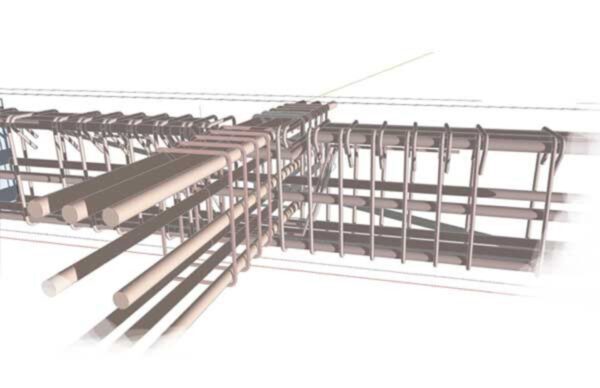

Reinforced concrete outriggers or structural steel trusses link the vertical building core laterally to the exterior framework.

This widens the structural base and increases torsional resistance vital for very tall, slender towers prone to vortex shedding, torsional oscillations and seismic impacts.

Purpose of Outrigger Systems

Outrigger systems serve several key stabilizing functions:

Widen Structural Base

Outriggers practically expand a tower’s footprint and base dimensions without requiring an actual larger building, preventing overturned moments.

Reinforce Building Core

The perimeter bracing fortifies the central concrete or steel core, allowing very high elevations on more minimal footprints.

Torsional Resistance

Outriggers reduce twisting from vortex shedding winds striking the building sides, seismic impacts trying to rotate the tower, and general loading shifts.

Column Shortening

Perimeter column compression and shortening gets distributed across more elements, preventing destabilizing differential column heights.

Foundational Alignment

The outriggers also help vertically align foundations, crucial for towers exceeding 500 meters where the earth’s curvature becomes a factor.

Principle Behind Outrigger Structural Systems

Conceptually, outrigger systems work similarly to the floats projecting from the sides of a canoe or paddle boat.

The extended floats widen the vessel’s beam, preventing tipped rollovers. By bracing the vulnerable core, outriggers allow extremely tall, slender towers to resist overturning forces.

The cantilevered trusses essentially create a wide “virtual” base framework. This uses diagonal and perimeter shear rigidity to share lateral forces across more structural surfaces.

Outriggers also limit column shortening and foundation inconsistencies.

Together this equates to enhanced stability and torsional resistance vital for record-setting contemporary high-rises built on exceptionally small footprints.

Types of Outrigger Structural Systems

There are several outrigger system configurations including:

Perimeter Outriggers

The most common orientation positions horizontal trusses or walls around the exterior edges linking the core to perimeter columns. This maximizes the base dimensions.

Mid-Level Outriggers

Outrigger trusses situated closer to a tower’s mid levels reduce forces concentrated lower down on perimeter systems while still widening stability.

Two-Way Outriggers

Adding secondary extensions running perpendicular to the exterior bracing forms a bridged “web” resisting bi-directional sway and rotation.

Belt Trusses

Connecting perimeter columns with horizontal belt trusses at regular intervals creates stacked virtual bases up the building’s height.

Mixed Systems

Many modern supertalls combine perimeter, mid-level and two-way outriggers for optimal multidirectional support customizable per site demands.

Advanced modeling helps engineers determine optimal outrigger quantity, size and placement tailored for geography, building usage, regs, etc.

Outrigger Design for High Rise Buildings

Designing outrigger systems requires balancing multiple architectural and structural objectives:

Program Goals

The owner’s needs influence outrigger placement to maximize rentable space and desired layouts. These guide embedding versus perimeter approaches.

** column spacing**

Closer exterior column spacing allows smaller outrigger elements that minimize rentable impacts.

** Building Shape and Orientation**

Asymmetrical, curved or unusual buildings require customized directional bracing for stability. Façade openings also affect layouts.

** Cost Efficiency**

Optimization balances performance, fabrication feasibility and construction budgets through material choices, modular parts, and integration.

With extensive coordination, architects and engineers decree robust outrigger schemes fulfilling both vision and safety at great heights.

Outrigger Structural System Architecture

Integrating outrigger systems while preserving aesthetic vision demands creative architectural detailing:

Enclosed within Structural Walls

Concrete or steel outrigger trusses fully embed inside core walls for minimal visibility. Exterior columns still visually read as supports.

Façade Ring Beams

Horizontal reinforcement belts around glass curtain walls hide structural transfers anchored to the columns.

**Aligned Transfer Girders **

Floor edge transfer beams synchronize perfectly with interior core braces using alignment to “hide” the links.

Ornamental Brackets

Decorative perimeter brackets or console elements disguise load transfers as architectural features.

Enclosed Mechanical Levels

Locating outriggers on mechanical floors eliminates rental space impacts while using necessary floor thickness to enclose supports.

With thoughtful coordination, outrigger systems discreetly bolster buildings behind the sceneswithout interrupting signature aesthetics.

Role of Outriggers in Tall Buildings

As height records continue to rise exponentially, outrigger inclusion becomes imperative:

Beyond 500 Meters

Virtually all supertalls exceeding 500 meters require outrigger assistance to resist whipping wind vortexes and seismic shifts threatening stability.

Slender Towers

Buildings with height/width ratios over 7:1 need wide base frameworks that outriggers provide to prevent overturning moments.

Residential Buildings

The uneven weight distributions in residential towers demand reinforced stability that outriggers deliver.

Sites With Poor Soil/Seismic Risks

Inadequate foundations or earthquake-prone zones require robust outrigger-boosted resistance.

Odd Shapes

Irregular building geometries prone to vortex shedding forces especially benefit from outrigger reinforcement.

While hidden inside, outriggers play an invaluable role reinforcing tall buildings behind the scenes.

Outrigger System for Skyscrapers

As cities compete through audacious architecture, record-setting skyscrapers rely on outrigger assistance to claim clouds:

Shanghai Tower

Twisting 632 meters into China’s stratosphere, Shanghai’s spectacular spiral form depends on eight perimeter outrigger trusses resisting typhoon buffets.

** ping An Finance Center**

melding four colossal columns through perpendicular outriggers, Shenzhen’s newly crowned 599 meter exemplar balances stunning beauty with structural innovation.

One World Trade Center

Poignantly soaring 1,776 feet skyward, Downtown Manhattan’s resurgence stands resiliently tall on robust outrigger reinforcement.

Around the globe, iconic skylines salute outrigger systems bolstering humanity’s reach toward the atmospheric unknown.

Core and Outrigger System Construction

Managing the logistical integration of dense building cores with perimeter frameworks requires thoughtful coordination phasing installation in sensible sequences:

1. Foundations

Deep excavations and concrete pours establish properly aligned subterranean supports for eventual tower loads above.

2. Central Core

The elevator core and interior structure forms the vertical backbone incrementally rising floor-by-floor.

3. Perimeter Columns

With the core underway, exterior columns follow behind installing the vertical elements outriggers will eventually bridge horizontally.

**4. Outrigger Assembly **

After perimeter progression, prefabricated outrigger trusses or horizontal reinforcements mechanically secure into place.

5. Testing

Engineers validate full integrations through real-world load testing confirming performances surpass modeling.

Careful orchestration of the layered components synthesizes into a single unified structure.

How Outriggers Support Tall Buildings

While hidden behind walls and glass, outriggers perform critical structural feats:

Torsional Resistance

Outriggers circling towers significantly widen the lateral force resistance perimeter. This counters rotational moments from vortex winds, quakes, and asymmetry that tall isolated cores cannot handle alone.

Column Axial Shortening

The whopping vertical compression in 400+ meter buildings can decrease column heights differentially across the tower. Outriggers share this shortening across more elements preventing destabilizing pillar mismatches.

Foundational Consistency

Subtle foundation sinkage becomes problematic on record-setting heights. Outriggers help align columns minimizing foundation differential settlements.

Though discreet, outriggers grant towers the capability to dramatically exceedlimits through clear structural logic.

Outrigger Trusses for High-rises

Numerous truss configurations effectively channel lateral forces from towering heights down to the foundations:

Diagonal Braces

X, V and K diagonal patterns bolster the core to exterior framework connection through triangulation for excellent torsional resistance and drift reduction.

Vierendeel Trusses

Rectangular frames using rigid joints instead of diagonals transfer shear across openings like windows or mechanical levels.

Ladder Frames

Stacked Vierendeel trusses create a modular extending ladder system crossing horizontal bands.

Wall Outriggers

Entire shear walls or concrete cores extending to the perimeter act as deep beam trusses transferring lateral loads.

With diverse options, engineers determine optimal outrigger schemes acutely suited to buildings’ custom contours and site constraints.

Reinforced Concrete Outriggers

Reinforced concrete cores already stabilize most towers, so extending shear walls, braces, and frames through R/C outriggers builds innately on these fundamental strengths:

Material Integration

Concrete outriggers extend from the building core sharing material strength, thermal expansion rates and construction methods for innate compatibility.

Continuity

Monolithic concrete links interiors to perimeter columns through unbroken mineral bonds unimpeded by fireproofing demands.

Ductility

Concrete’s ductile nature uniquely flows with gradual failures preventing sudden collapse.

Stiffness

Shear walls and wall-frame combinations achieve excellent rigidity vital for resistance.

Blending interior/exterior frameworks through solid outrigger continuity composes towers with resilient strength.

Advantages of Perimeter Outriggers

Situating outriggers around the building circumference optimizes bracing potential:

Maximizes Dimensions

Full perimeter outriggers vastly widen tower bases up to 175% larger dramatically improving stability and torsional resistance.

Core Protection

This extensive widening directly reinforces the most vulnerable central core zones.

Adaptable Configurations

Adjustable perimeter placement accommodates symmetrical or irregular site layouts.

Phased Construction

Modules allow perimeter installation without interfering with central core erection.

Ideally embracing buildings with stalwart stability, full perimeter outriggers manifest towers’ soaring potential.

Outrigger System Wind Loads

With elevations surpassing previous records, modern towers endure exceptional wind shear challenges:

Fatigue Cycling

Swaying back-and-forth through wind vortexes induces enormous cyclic stress fatigue taxing materials over decades.

Torsional Buffeting

Spiraling vortices striking sides applies destabilizing rotation amplified by height into massive moment forces.

Uplift Pressures

Air currents flowing around towers dynamically pressurizes the windward face while creating partial vacuum suction on upper leeward surfaces.

Fluttering

Negative pressures regions produce unstable aeroelastic fluttering of exterior glass or concrete cladding elements.

Outriggers structurally resist all these colossal demands ensuring tall buildings stand safely secured by their foundations against nature’s imposed edge cases.

Conclusion

Beyond dazzling heights and daring designs, hidden outrigger systems structurally uphold many audacious towering icons dominating 21st century skylines.

Their understated role reinforcing soaring ambitions through lateral braces, torsion resistance and stability alignments manifests the incredible ascents.

So while outriggers avoid the spotlight, instead working discreetly inside walls, they truly empower these cutting-edge towers balancing remarkable optimism with safety assurances.

Through persistently uplifting hotels, offices and homes closer to the clouds, outriggers ensure people comfortably experience the vertical frontier.