From soaring skyscrapers to expansive airports, many of the awe-inspiring structures in our built environment rely on advanced vertical support from steel columns.

Serving as the backbone upholding these ambitious designs, steel columns leverage unique properties that set them apart as prized structural components.

This strength, stiffness, and versatility explains steel’s dominance as the column material of choice for numerous civil engineering wonders worldwide.

What are Steel Columns?

Steel columns are vertical structural members used to support compressive loads in a building. They transfer weight from beams and slabs above down to the foundation.

Steel offers high strength-to-weight ratio so columns can span greater heights without buckling.

Types of Steel Columns

Steel columns take on different cross-sectional shapes tailored to their structural demands. Common structural steel column types include:

W-Shape Columns

Widely used “I-beam” columns offering excellent strength-to-weight ratios. The flanges resist bending while the web handles shear stress. W columns have high axial load capacity perfect for framing tall buildings.

Box Columns

Hollow structural sections shaped like squares or rectangles. Often used in high-rise buildings, their box-shaped form allows very tall columns without buckling. Efficient at handling high compressive stresses.

Pipe Columns

Circular hollow sections fabricated from steel pipe. Their rounded contour receives consistent compressive stresses across the section. Useful in exposed exterior settings.

Tapered Columns

Columns that transition from a deeper section at the base to a more shallow profile at the top. This reduces overall steel tonnage while still providing sufficient strength at each point along the height.

Composite Columns

Concrete-encased steel columns gaining strength from both materials. The concrete protects the inner steel from fire/corrosion while the steel adds compression and shear capacity.

The optimal shape fits the structural context, considering axial stresses, lateral loads, and constructability. Advanced analysis informs intelligent shaping.

Applications of Steel Columns

With their unique advantages, steel columns serve as foundational supports across nearly every type of building and structure:

High-Rise Construction – Slender steel columns enable extreme heights like skyscrapers by providing immense strength from small cross-sectional areas. Engineers cleverly design tapered or layered columns.

Long-Span Structures – Steel efficiently handles heavy loading across wide open interior spaces like airports, convention centers, and stadiums. Strong columns allow fewer interior supports.

Seismic Resistance – Ductile steel columns withstand earthquake forces through controlled plastic bending and damping devices. These collapse-prevention measures are vital in seismic zones.

Coastal and Waterfront Areas – Durable corrosion-resistant steel alloys allow columns exposed to marine environments or moisture. Maintenance is less intensive than other materials.

Renovation Projects – Existing buildings get upgraded with new floors or roofs atop lightweight steel columns which impose minimal added foundation load.

Temporary Structures – Adjustable modular steel column systems serve temporary venues like stages or exhibition halls before disassembly and reuse.

Steel empowers innovators to defy conventions in structural engineering across virtually any application. Advanced steel alloys and production methods will only expand construction possibilities moving forward.

components of a steel column

- Column Shaft – This is the main body of the structural steel section. Common forms include I-beams, channels, tubes, or structural pipe.

- Base Plate – A steel plate welded to the bottom end of the column to interface with the foundation or structure below. It helps spread the column load.

- Anchor Bolts – High strength bolts that secure the column’s base plate to the concrete foundation or steel beams/girders below. They firmly fix the column alignment.

- Connection Details – Beam-to-column or truss-to-column connections are usually welded or bolted. They may include continuity plates, stiffeners, or gusset plates.

- Splice Connections – For taller columns delivered in multiple sections, field splice connections join shaft segments together on site.

- Lateral Bracing – Horizontal bracing frames, knee braces or moment connections provide lateral stability preventing the column from buckling sideways.

- Fire Protection – Sprayed coatings or concrete encasement enhance fire resistance ratings.

- Miscellaneous Plates – Shear studs, bearing stiffeners, or rebar cages may supplement joints.

Understanding these components aids in designing, detailing, fabricating and installing robust steel column systems in new structures.

Design Considerations

Engineers evaluate:

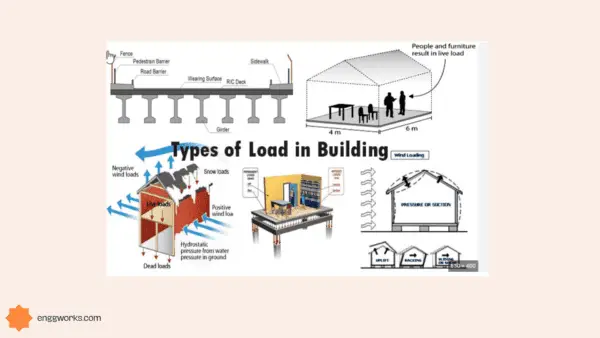

- Loading – Dead, live, wind, seismic. Higher loads need thicker columns.

- Column Height – Increasing unsupported length risks buckling failure.

- Connection Details – Welded, bolted, or riveted. Affects constructability.

- Fire Rating – Insulating coatings improve fire resistance.

- Serviceability – Deflection limits prevent floor vibrations/cracking.

Best Steel Types for Columns

ASTM A36, A572, A913, A992 are common structural steel grades. Select based on:

- Yield Strength – Resistance to deformation under load.

- Weldability – Ease of welding during fabrication/construction.

- Corrosion Resistance – Protection for harsh settings.

- Cost – Balance performance and budget.

Constructing Steel Columns

Main steps include:

- Fabricate steel members to specified dimensions and coatings

- Prepare foundation with base plate anchor bolts

- Erect columns with crane and temporary bracing

- Install beam/truss connections using welding/bolting

- Add lateral bracing and bridging system

- Finish encasing/fireproofing columns as needed

Conclusion

Steel columns provide versatile vertical support to buildings across a range of loading conditions. Engineers optimize strength, serviceability, and construction efficiency through careful column shaping, detailing, and material selection.

When standing on a high-rise roof or under a soaring airport terminal, one appreciates the towering heights made possible by steel’s towering strength.