Reinforced concrete columns are a fundamental structural element in modern construction, combining the compressive strength of concrete with the tensile strength of steel reinforcement. These columns have revolutionized the building industry, enabling the construction of taller, stronger, and more durable structures.

The concept of reinforced concrete dates back to the mid-19th century when inventors and engineers began experimenting with the idea of embedding metal within concrete to improve its tensile properties.

here are significant advantages over traditional building materials:

- Strength and durability: Reinforced concrete columns offer exceptional compressive strength and can withstand heavy loads, making them ideal for multi-story buildings and combination of concrete with steel provide excellent durability, resistance to weathering, and fire resistance.

- Versatility in design: Reinforced concrete columns can be cast in various shapes and sizes, allowing architects and engineers to create diverse and innovative designs.

- Cost-effectiveness: The raw materials for reinforced concrete columns, namely cement, aggregates, and steel, are relatively inexpensive and widely available.

- Sustainability: Reinforced concrete columns have a long service life, reducing the need for frequent replacements and contributing to the overall sustainability of the structure.

What is reinforced concrete columns?

Reinforced concrete columns are structural elements that are widely used in the construction of buildings, bridges, and other structures. They are designed to support vertical loads and transfer them to the foundation.

The introduction of reinforced concrete columns has had a profound impact on the construction industry, enabling the creation of more robust, efficient, and aesthetically pleasing structures. As the demand for sustainable and resilient infrastructure continues to grow, reinforced concrete columns will likely remain a crucial component in the built environment for years to come.

Here’s a detailed explanation of reinforced concrete columns:

Composition:

- Concrete: Columns are made of high-strength concrete, typically with a compressive strength ranging from 20 to 50 MPa (3,000 to 7,000 psi).

- Reinforcement: Steel reinforcing bars (rebar) are embedded within the concrete to provide tensile strength and ductility.

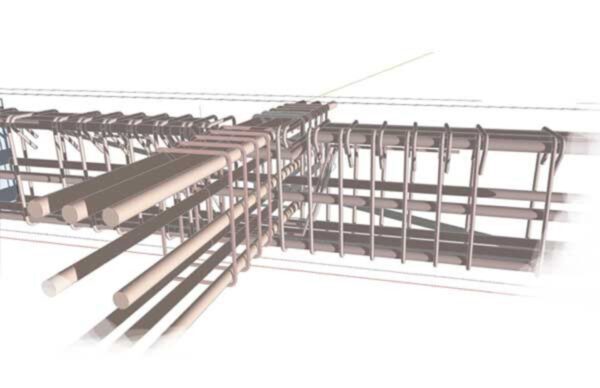

Reinforcement arrangement:

- Longitudinal reinforcement: Vertical steel bars run along the length of the column to resist bending moments and provide tensile strength.

- Transverse reinforcement (stirrups or ties): Horizontal steel bars or wires are placed at regular intervals along the column to confine the concrete, prevent buckling of the longitudinal bars, and provide shear resistance.

Construction process:

- Formwork: Temporary molds are used to cast the concrete column in the desired shape and size.

- Reinforcement placement: Rebar is fabricated and placed within the formwork according to the design specifications.

- Concrete pouring: Fresh concrete is poured into the formwork and vibrated to ensure proper consolidation and eliminate air voids.

- Curing: The concrete is allowed to cure and gain strength over time, typically for 28 days.

Types of reinforced concrete columns in construction

There are several types of reinforced concrete columns used in construction, each with its own characteristics and applications. The main types of reinforced concrete columns are:

Tied Columns:

- Tied columns are the most common type of reinforced concrete columns.

- They consist of longitudinal reinforcement bars (rebars) that run vertically along the length of the column.

- The longitudinal bars are tied together with transverse reinforcement (stirrups or ties) at regular intervals.

- Stirrups help in resisting shear forces and provide confinement to the concrete core.

Spiral Columns:

- Spiral columns feature a continuous spiral of reinforcement that wraps around the longitudinal bars.

- The spiral reinforcement provides excellent confinement to the concrete core, enhancing the column’s ductility and ability to withstand seismic loads.

- Spiral columns are commonly used in structures located in seismic zones or where high ductility is required.

Composite Columns:

- Composite columns combine structural steel shapes (like I-sections or hollow sections) with reinforced concrete.

- The steel shape is typically placed at the center of the column and is surrounded by reinforced concrete.

- Composite columns take advantage of the strengths of both materials – the high tensile strength of steel and the compressive strength of concrete.

- They are often used in high-rise buildings and structures with large loads.

Prestressed Columns:

- Prestressed columns incorporate high-strength steel tendons or cables that are tensioned before the concrete is cast.

- The prestressing force introduces compressive stresses in the concrete, counteracting the tensile stresses that occur under loading.

- Prestressed columns can span longer distances and carry heavier loads compared to conventional reinforced concrete columns.

Short Columns:

- Short columns have a small slenderness ratio, meaning their height is relatively small compared to their cross-sectional dimensions.

- They are primarily subjected to axial compressive loads and have a low risk of buckling.

- Short columns are commonly found in low-rise structures and as supporting elements in foundations.

Slender Columns:

- Slender columns have a high slenderness ratio, with their height being several times larger than their cross-sectional dimensions.

- They are prone to buckling under compressive loads and require careful design considerations.

- Slender columns are often encountered in tall structures, such as high-rise buildings or industrial facilities.

Biaxially Loaded Columns:

- Biaxially loaded columns are subjected to bending moments and compressive forces in both principal axes simultaneously.

- They require a more complex design approach to account for the combined effects of axial loads and biaxial bending.

- Biaxially loaded columns are common in structures with unsymmetrical loading conditions or where lateral loads are significant.

Design considerations for reinforced concrete columns

When designing reinforced concrete columns, several key considerations must be taken into account to ensure the structural integrity, safety, and performance of the column. Here are the main

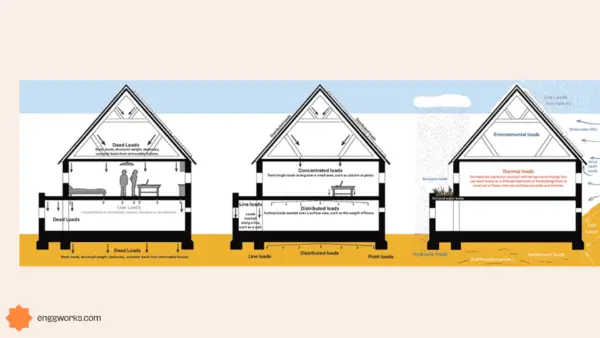

Axial Load and Bending Moment:

- Columns are subjected to axial compressive loads and bending moments due to the weight of the structure and lateral loads (such as wind or seismic forces).

- The design must account for the combined effects of axial load and bending moment, ensuring that the column has sufficient capacity to resist these forces.

- Interaction diagrams are used to determine the column’s capacity under different combinations of axial load and bending moment.

Slenderness Ratio:

- The slenderness ratio is the ratio of the column’s unsupported length to its least lateral dimension.

- Slender columns (with high slenderness ratios) are more susceptible to buckling and require additional design considerations.

- The slenderness ratio affects the column’s capacity and influences the choice of reinforcement and cross-sectional dimensions.

Reinforcement:

- The amount, type, and arrangement of reinforcement significantly impact the column’s strength and ductility.

- Longitudinal reinforcement bars (rebars) are designed to resist bending moments and provide tensile strength.

- Transverse reinforcement (stirrups or ties) is provided to resist shear forces, confine the concrete core, and prevent buckling of the longitudinal bars.

- The reinforcement must be properly anchored and have sufficient development length to ensure effective load transfer.

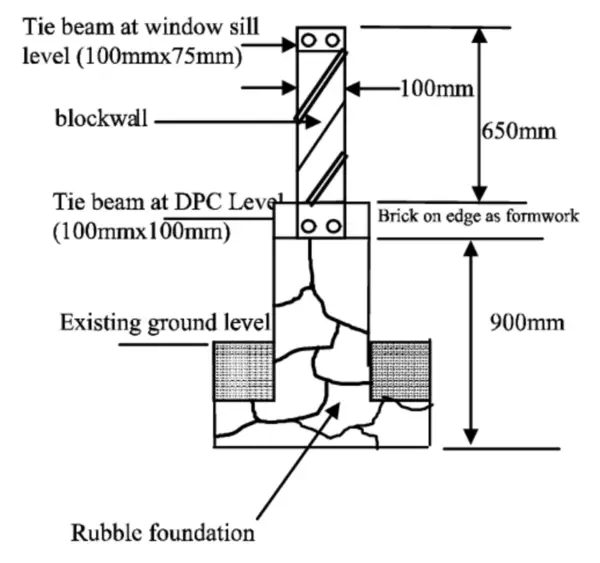

Concrete Cover:

- Concrete cover is the distance between the surface of the reinforcement and the outer surface of the concrete.

- Adequate concrete cover is necessary to protect the reinforcement from corrosion and fire.

- The cover thickness depends on the environmental exposure conditions and the required fire resistance rating.

Durability:

- The column must be designed to withstand environmental factors such as moisture, temperature changes, and chemical attacks.

- Proper concrete mix design, adequate concrete cover, and appropriate reinforcement detailing are essential for ensuring the column’s durability.

- In aggressive environments, additional protective measures (such as coatings or corrosion-resistant reinforcement) may be necessary.

Serviceability:

- Serviceability refers to the column’s performance under normal use conditions, considering factors such as deflection, cracking, and vibration.

- The column should be designed to limit excessive deflections and crack widths to maintain the structure’s functionality and aesthetic appearance.

- Long-term effects like creep and shrinkage should also be considered in the design.

Constructability:

- The design should consider the ease of construction and the availability of materials and skilled labor.

- The placement of reinforcement and the use of formwork should be practical and efficient.

- Complex reinforcement arrangements or difficult-to-construct shapes should be avoided unless necessary.

Economic Considerations:

- The design should aim for an economical solution that balances the cost of materials, labor, and maintenance.

- Optimizing the column size, reinforcement layout, and construction methods can help reduce overall costs without compromising structural integrity.

Compatibility with Other Structural Elements:

- The column design should consider its connection and interaction with other structural elements like beams, slabs, and foundations.

- Proper detailing of reinforcement at the connections is crucial for ensuring the transfer of forces and maintaining the structural integrity of the system.

Advantages of reinforced concrete columns:

- High compressive strength: Concrete has excellent resistance to compressive loads.

- Durability: Reinforced concrete columns are durable and can withstand various environmental conditions.

- Fire resistance: Concrete provides inherent fire resistance, protecting the reinforcement and maintaining structural integrity.

- Versatility: Columns can be designed in various shapes and sizes to accommodate architectural and structural requirements.

Limitations and challenges:

- Corrosion of reinforcement: If the concrete cover is insufficient or cracks develop, the reinforcement may be exposed to moisture and corrode over time.

- Shrinkage and creep: Concrete undergoes volumetric changes due to shrinkage and creep, which can affect the column’s long-term performance.

- Difficulty in modification: Once constructed, reinforced concrete columns are difficult to modify or strengthen without significant intervention.

Conclusion

In conclusion, reinforced concrete columns are a vital component of modern construction, playing a crucial role in supporting structures and ensuring their stability. By combining the compressive strength of concrete with the tensile strength of steel reinforcement, these columns offer numerous advantages, including high load-bearing capacity, durability, fire resistance, and versatility in design.

Advancements in material science, construction techniques, and computational tools have further enhanced the capabilities of reinforced concrete columns. Innovations like high-strength concrete, fiber-reinforced polymers (FRP), and self-consolidating concrete have opened up new possibilities for column design and performance.

In summary, reinforced concrete columns have proven to be a game-changer in the realm of construction, offering unparalleled strength, durability, and flexibility. Their significance in shaping the built environment cannot be overstated, and they will undoubtedly continue to play a pivotal role in the future of construction.