What is a Roof Beam?

Roof beams are essential structural elements that support the weight of a roof and ensure its stability.

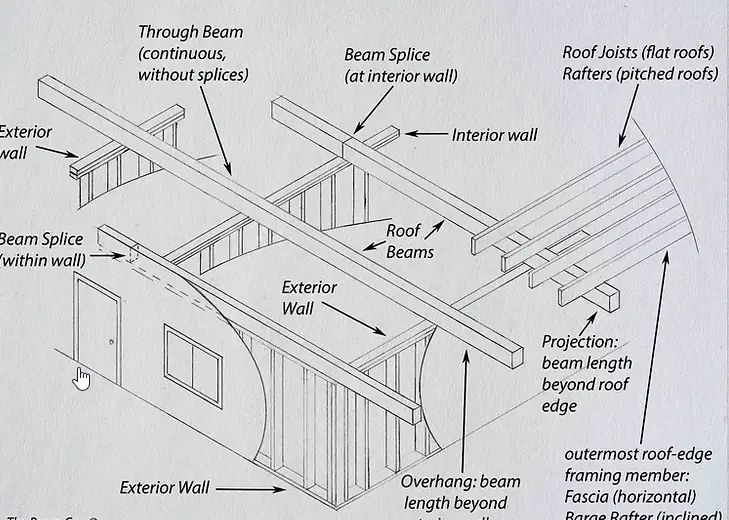

A roof beam is a horizontal structural member that spans the distance between two supports, typically walls or posts. Its primary function is to carry the weight of the roof deck, sheathing, and any additional loads such as snow or wind. Roof beams are crucial in maintaining the structural integrity of a building.

Types of Roof Beams

There are several types of roof beams available, each with its own unique characteristics and benefits. The choice of beam type depends on various factors such as the building’s design, load requirements, span, and budget. Let’s explore some of the most common types of roof beams:

Glued Laminated Timber (Glulam) Beams: Glulam beams are engineered wood products made by gluing together individual layers of lumber. They offer excellent strength-to-weight ratio, dimensional stability, and can be custom-made to suit specific design requirements. Glulam beams are commonly used in residential, commercial, and industrial buildings.

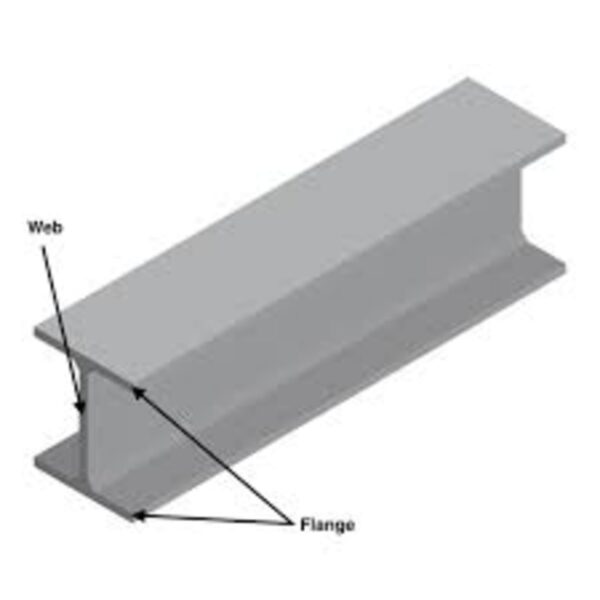

Steel Beams: Steel roof beams are known for their high strength, durability, and ability to span long distances. They are often used in commercial and industrial buildings where heavy loads and wide spans are common. Steel beams come in various shapes, such as I-beams, wide flange beams, and hollow structural sections (HSS).

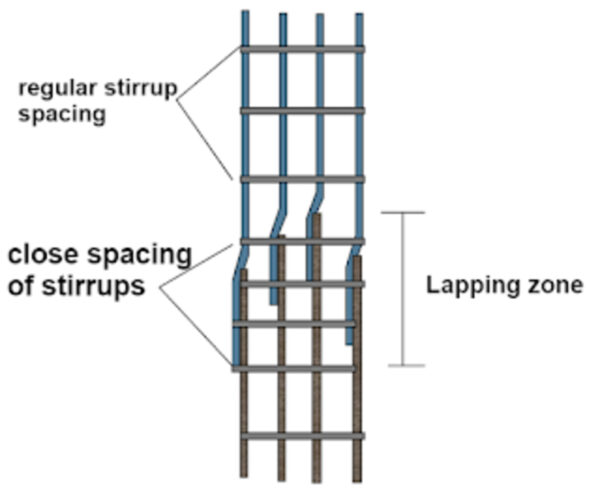

Reinforced Concrete Beams: Reinforced concrete roof beams are made of concrete with embedded steel reinforcement bars (rebar). They provide excellent fire resistance, durability, and can be cast into various shapes and sizes. Reinforced concrete beams are commonly used in commercial, industrial, and institutional buildings.

Parallel Chord Trusses: Parallel chord trusses are engineered roof beams that consist of top and bottom chords connected by vertical and diagonal web members. They are lightweight, efficient, and can span long distances. Parallel chord trusses are often used in residential, commercial, and agricultural buildings.

Open Web Steel Joists: Open web steel joists are lightweight, cost-effective roof beams made of steel top and bottom chords connected by web members. They allow for easy installation of utilities and ductwork through the open web spaces. Open web steel joists are commonly used in commercial and industrial buildings.

Timber Beams: Timber roof beams are made from solid sawn lumber and are often used in residential and small commercial buildings. They offer a natural, rustic appearance and can be left exposed for aesthetic purposes. However, timber beams have limitations in terms of span and load-bearing capacity compared to engineered wood products like Glulam.

Structural Insulated Panels (SIPs): While not strictly a type of roof beam, SIPs are a modern, energy-efficient alternative to traditional roof framing. SIPs consist of an insulating foam core sandwiched between two layers of structural sheathing, creating a strong, airtight, and well-insulated roof system.

When selecting the type of roof beam for a project, it is essential to consult with a structural engineer who can assess the specific requirements and recommend the most suitable option. Factors such as the building’s design, load requirements, span, fire resistance, and budget should be carefully considered to ensure a safe, durable, and efficient roof structure.

Roof Beam Design

Roof beam design is a critical aspect of ensuring the structural integrity and safety of a building. The design process involves calculating the required size, spacing, and material of the beams based on various factors such as the roof span, load, and building codes. Here are some key considerations in roof beam design:

- Load Analysis: The first step in roof beam design is to determine the loads that the beams will be subjected to. This includes dead loads (the weight of the roof structure itself) and live loads (additional weights such as snow, wind, or occupants). The designer must also consider any concentrated loads, such as rooftop equipment or solar panels.

- Span and Spacing: The span of the roof beam (the distance between supports) and the spacing between beams are crucial factors in determining the required size and material of the beams. Longer spans and wider spacing generally require larger or stronger beams to ensure adequate support and prevent excessive deflection.

- Material Selection: The choice of roof beam material depends on various factors such as the required strength, fire resistance, durability, and aesthetics. Common materials include wood (dimensional lumber, Glulam, LVL), steel (I-beams, wide flange beams), and reinforced concrete. The designer must consider the properties of each material and select the most appropriate option for the specific project.

- Building Codes and Standards: Roof beam design must comply with local building codes and standards, such as the International Building Code (IBC) or the American Society of Civil Engineers (ASCE) standards. These codes specify minimum requirements for factors such as load combinations, deflection limits, and fire resistance ratings.

- Connections and Supports: The design of roof beam connections and supports is equally important to ensure the overall stability of the structure. The designer must specify appropriate connection methods (e.g., bolts, hangers, or brackets) and ensure that the supports (walls, columns, or posts) are adequate to transfer the loads from the beams to the foundation.

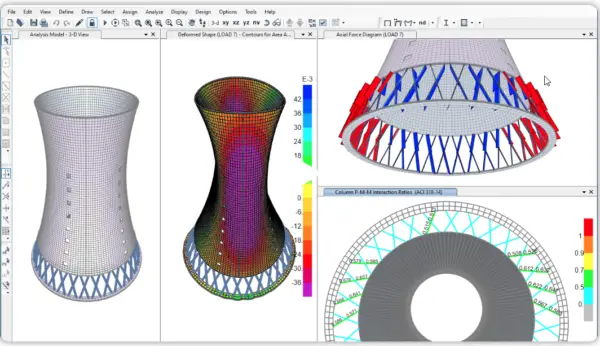

- Software and Tools: Modern roof beam design often involves the use of specialized software and tools, such as structural analysis programs and Building Information Modeling (BIM) software. These tools help designers create accurate 3D models, analyze load paths, and optimize beam sizes and configurations for efficiency and cost-effectiveness.

- Collaboration with Other Disciplines: Roof beam design requires close collaboration with other disciplines, such as architects, mechanical and electrical engineers, and construction professionals. The designer must coordinate with these teams to ensure that the roof beam layout accommodates any required openings, penetrations, or attachments, and that the overall design is constructible and efficient.

Roof Beam Construction Details

Roof beam construction details vary depending on the type of beam and the building’s requirements. Proper detailing is crucial for ensuring the structural integrity, durability, and performance of the roof system. Here are some common roof beam construction details:

Glulam Beam Connections: Glued laminated timber (Glulam) beams are typically connected using metal plates, hangers, or brackets. These connectors are designed to transfer loads effectively and accommodate any necessary adjustments or movements. Common connection details include:

- Metal plate connectors: Steel plates are glued or bolted to the beam ends and then bolted to the supporting members.

- Hanger connections: Metal hangers are used to connect beams to walls or other supporting members, allowing for easy installation and adjustability. Bracket connections: Steel brackets are bolted or welded to the beam ends and then connected to the supporting members.

Steel Beam Connections: Steel roof beams can be connected using various methods, such as welding, bolting, or using specialized connectors. Common steel beam connection details include:

- Welded connections: Steel beams can be welded directly to supporting members or to steel plates that are then connected to the supports.

- Bolted connections: Steel beams can be bolted to supporting members using high-strength bolts and pre-drilled holes.

- Clip angle connections: Steel clip angles are bolted or welded to the beam ends and then connected to the supporting members.

Reinforced Concrete Beam Connections: Reinforced concrete roof beams are typically cast monolithically with the supporting members (walls or columns) or connected using reinforcing bars (rebar) and concrete. Common reinforced concrete beam connection details include:

- Monolithic connections: The beam and supporting members are cast as a single unit, ensuring a continuous load path and eliminating the need for additional connectors.

- Rebar connections: Reinforcing bars extend from the beam ends and are embedded into the supporting members, creating a strong and durable connection.

Bearing and Seating: Proper bearing and seating details are essential to ensure that the roof beams are properly supported and can transfer loads effectively. This includes providing adequate bearing length on the supporting members, using bearing pads or plates to distribute loads, and ensuring that the beams are level and properly aligned.

Lateral Bracing: Roof beams may require lateral bracing to prevent lateral-torsional buckling and ensure stability under wind or seismic loads. Lateral bracing can be provided using diagonal bracing members, blocking between beams, or by designing the roof deck to act as a diaphragm.

Penetrations and Openings: Roof beams may need to accommodate penetrations or openings for utilities, ductwork, or skylights. Proper detailing around these openings is crucial to maintain the structural integrity of the beam and prevent water infiltration. This may involve reinforcing the beam around the opening, using specialized flashing or sealants, or designing the opening to transfer loads effectively.

Fire Protection: In some cases, roof beams may require fire protection to meet building code requirements or to ensure the safety of occupants. This can be achieved through the use of fire-resistant materials (e.g., concrete or protected steel), applying fire-resistant coatings or insulation, or enclosing the beams in fire-rated assemblies.

Common roof beam materials include:

- Wood: Dimensional lumber, engineered wood products like Glulam and LVL (laminated veneer lumber)

- Steel: I-beams, wide flange beams, and tube steel

- Reinforced concrete: Precast or cast-in-place beams

Each material has its own advantages and disadvantages in terms of strength, cost, and ease of installation.

Calculating Roof Beam Size

Calculating roof beam size is a critical step in ensuring that the roof structure is safe, stable, and capable of supporting the required loads. It’s important to note that calculating roof beam size is a complex process that requires knowledge of structural engineering principles and familiarity with the relevant building codes and standards.

Here’s a detailed look at the steps involved in calculating roof beam size:

- Determine the Beam Span: The first step is to measure the clear span of the beam, which is the distance between the supports (walls, columns, or posts). This is a crucial factor in determining the required beam size, as longer spans generally require larger or deeper beams.

- Calculate the Design Loads: Next, calculate the design loads acting on the beam, which typically include:

Dead Load (DL): The weight of the roof structure itself, including the decking, insulation, and roofing materials.

Live Load (LL): Additional weights such as snow, wind, or occupants, as specified by local building codes.

Other Loads: Depending on the project, there may be other loads to consider, such as seismic loads or concentrated loads from rooftop equipment. - Select the Beam Material: Choose the appropriate beam material based on the project requirements, such as wood (dimensional lumber, Glulam, LVL), steel (I-beams, wide flange beams), or reinforced concrete. Each material has its own unique properties, such as strength, stiffness, and weight, which affect the required beam size.

- Determine the Allowable Stresses: Consult the relevant design codes and standards to determine the allowable stresses for the chosen beam material. These allowable stresses are based on factors such as the grade or quality of the material, duration of the load, and environmental conditions.

- Calculate the Required Section Modulus: The section modulus is a measure of a beam’s resistance to bending, and it depends on the beam’s cross-sectional shape and size. To calculate the required section modulus (S), use the following formula: S = (M × 12) ÷ Fb Where:

S = Section modulus (in³)

M = Maximum bending moment (ft-lbs)

Fb = Allowable bending stress (psi)

The maximum bending moment (M) can be calculated based on the beam span and loading conditions, using equations from structural engineering handbooks or software. - Select a Beam Size: Using the required section modulus, select a beam size from the available options for the chosen material. Manufacturers typically provide tables or charts that list the section properties (including section modulus) for various beam sizes. Choose a beam size with a section modulus equal to or greater than the required value.

- Check Deflection: In addition to strength, the beam must also meet the deflection criteria specified by the building codes. Calculate the expected deflection of the selected beam size under the design loads and compare it to the allowable deflection limits. If the expected deflection exceeds the allowable limit, choose a larger or deeper beam size.

- Verify Shear Capacity: Check the shear capacity of the selected beam size to ensure that it can safely resist the maximum shear forces. If necessary, adjust the beam size or material to meet the shear requirements.

- Consider Other Factors: Depending on the project, there may be other factors to consider when selecting the final beam size, such as fire resistance requirements, vibration control, or architectural constraints.

Conclusion

Roof beams play a vital role in ensuring the structural stability and safety of a building. Understanding the types, design, construction, and maintenance of roof beams is essential for architects, engineers, and builders.

By following proper design principles, installation techniques, and maintenance practices, we can create durable and reliable roof structures that stand the test of time.