Concrete cracks are a common occurrence in foundations, walls, floors, and slabs. While cracks may seem purely aesthetic, they can lead to further deterioration if left untreated.

This article explores why cracks form, how to identify common types of cracks in concrete, and proven methods for repairing cracks in residential and commercial concrete.

Why Do Cracks Form in Concrete?

Concrete naturally shrinks as it cures, leading to internal stresses that often cause cracks.

Other factors like freeze-thaw cycles, soil settlement, structural loads, corrosion, and poor construction practices also produce cracks. Identifying the root cause is key to proper crack repair.

How to Repair Cracks in Concrete Walls

Vertical or diagonal cracks in foundation and retaining walls signal settlement or bowing issues. Thankfully, various methods can stabilize and fill wall cracks:

- Epoxy injection flows deep into cracks for structural repairs. Epoxies bond the crack sides together.

- Rout and seal widens cracks to insert flexible sealants. This allows continued movement while preventing water intrusion.

- Resin injection works similar to epoxy with added strengthening from aggregate fillers. It restores structural integrity.

- Hydraulic cements provide quick, inexpensive repairs for hairline dormant cracks. However, they are prone to cracking again.

Professional structural evaluations help determine suitable wall crack repairs.

What Causes Cracks in Concrete Floors?

Indoors, cracks in concrete floors typically arise from minor ground settling, poor joint spacing, or excessive loads.

Outdoors, freeze-thaw cycles and soil heaving also cause cramcking. The patterns and locations reveal the category:

- Random cracks signal curing issues with weak concrete.

- Uniform slabs with regular cracks indicate proper joints spaced too far apart.

- Cracks near foundations or corners show settlement problems.

- Jagged cracks through exterior sections result from expanding and contracting soil.

Methods for Repairing Cracks in Concrete

Again, epoxy and resin injection provide durable repairs by rebonding cracks from the inside out. Other fixing options include:

- Routing and sealing – Widening via diamond blade before applying flexible polyurethane seals.

- Gravity feed – Liquid repair products poured directly into cracks for deep penetration.

- Patching compounds – Polymer-modified cements that harden like concrete. Useful for surface-level repairs.

- Flexible grout – Siliconized acrylic-based materials that allow movement while sealing cracks.

Professional evaluation determines suitability based on crack width, depth, location, and underlying cause.

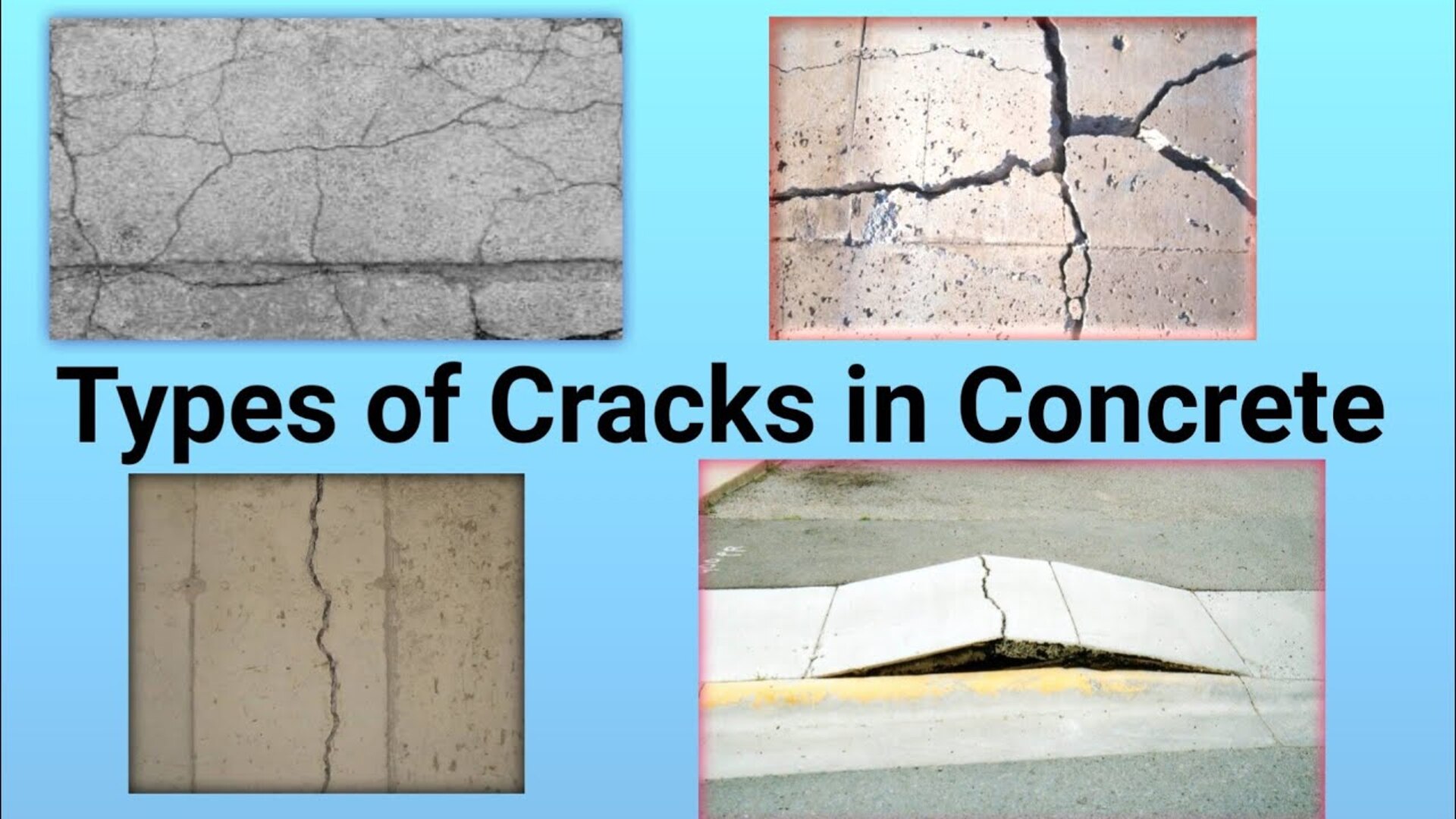

Identifying Types of Cracks in Concrete

Categorizing the crack pattern sheds light on its origin so repairs treat the cause, not just the symptom. Common concrete crack types include:

- Hairline cracks – Superficial cracks under 1/16-inch wide, often from minor shrinkage.

- Dormant cracks – Narrow stationary cracks with little movement.

- Active cracks – Wider cracks still expanding from instability or external forces.

- Structural cracks – Deep cuts through sections, indicating flaws and settlement.

- Craze/map cracks – Superficial interconnected random cracks from curing issues.

- Corner breaks – Triangular chunks breaking near building corners or openings.

- Spalls – Flaking surface pitting from freeze-thaw damage and embedded contaminants.

again, crack origin determines suitable repair methods. Misinterpreting crack patterns leads to failed fixes.

Diagnosing Causes of Cracks in Concrete

A professional structural evaluation is prudent before attempting repairs. This examines:

- Crack characteristics – Type, length, width progression, pattern, location.

- Concrete condition – Age, strength, air entrainment, contamination.

- Supporting foundation – Integrity, settlement, heaving.

- Site characteristics – Soil type, drainage, exposure to weather elements.

- Loading conditions – Static design capacity versus actual sustained loads.

Forensic investigations determine if structural overload, subsidence, thermal changes, or material flaws caused cracks. This prevents covering up underlying issues with superficial crack patches.

Treating Spider Web Cracks in Concrete

Dense spider web crack networks require stabilization before sealing materials fill cracks.

First, any ongoing movement gets addressed – like sealing exterior cracks to prevent seasonal water penetration expanding cracks further. Then:

- Diluted epoxies mechanically lock loose material in place to prevent further deterioration.

- Supplemental reinforcement gets installed such as rebar nailing, composite building wraps, or fiber meshes. This bridges cracks and strengthens cracks likely to propagate.

- After stabilization, flexible polyurethane or urethane sealants fill cracks while allowing slight seasonal expansion contractions without tearing open repeatedly.

Fixing Settlement Cracks in Concrete Slabs

Cracks near foundations signal void spaces under slabs allowing downward settling from erosion or compression.

Injecting high-density polyurethane foam fills voids, elevating and supporting slabs to prevent ongoing subsidence cracking.

This stabilizes slabs prior to patching cracks with suitable sealing compounds.

Repairing Dormant Cracks in Concrete Basement Walls

Empty dormant cracks allow water intrusion and freeze-thaw damage during winter months.

While epoxy injection permanently bonds structural repairs, flexible polyurethane sealants prevent water entering dormant cracks at lower costs.

Monitoring via crack gauges verifies cracks remain stationary over time.

Understanding Shrinkage Cracks in Concrete Pavement

Date stamps help determine if random shrinkage cracks appeared within concrete pavement’s year one curing phase or indications of instability.

Hairline cracks get expected from standard curing. For minor shrinkage cracks under 1/8 inch, flexible sealants allow slight movement while keeping penetrable pathways closed.

Larger cracks require slab stabilization, void filling, and restoration.

In summary, identifying the type, origin, and characteristics of concrete cracks informs suitable repair techniques – ranging from surface sealing to structural rehabilitation.

While cracks inherently form in concrete, timely repairs prevent extensive unattractive damage requiring full section replacements.