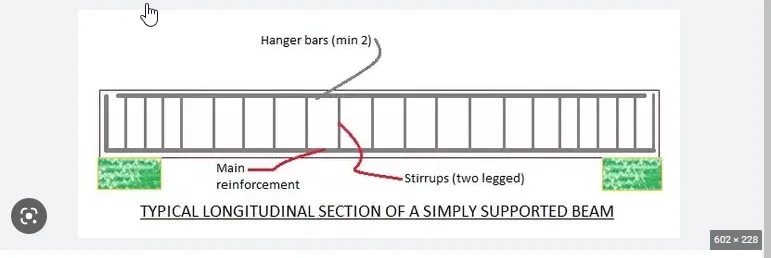

A RCC beam is a structural member designed to resist bending and shear forces along with supporting loads. The beam is made of a concrete that has been reinforced with steel bars or mesh, increasing the structure’s tensile strength and enabling it to withstand bending and shear pressures.

It stands as a cornerstone of structural design, serving as a critical load-bearing element in various construction projects. Understanding its intricacies is essential for civil engineers, as they play a vital role in ensuring the safety and stability of buildings, bridges, and other infrastructure.

Why you need a RCC Beam?

RCC beam stands for reinforced cement concrete beam. It is a structural element that supports the load of a building or a structure.

Analysis lies the understanding of shear force and bending moment formula, which provides the necessary framework for determining the appropriate beam dimensions and reinforcement requirements.

RCC beam consists of concrete and steel bars that are embedded in the concrete. The concrete provides resistance to compression, while the steel bars provide resistance to tension. Together, they form a strong and durable beam that can withstand various forces and stresses.

This beam has many advantages over other types of beams, such as wood, steel, or brick. Some of the benefits are:

- It is fire-resistant and does not burn easily.

- It is corrosion-resistant and does not rust or decay.

- It is economical and easy to construct and maintain.

- It is flexible and can be molded into any shape and size.

- It is versatile and can be used for different purposes, such as beams, columns, slabs, foundations, etc.

RCC beam is an essential component of any building or structure. It provides stability and strength to the entire structure and ensures its safety and durability. Without RCC beam, the structure would collapse under its own weight or external forces. Therefore, RCC beam is a must-have for any construction project.

How to Make RCC Beam?

A reinforced concrete (RCC) beam is a structural element that can withstand both compression and tension forces. RCC beams are commonly used in buildings, bridges, and other structures that require strength and durability. In this blog post, we will explain how to make an RCC beam in four simple steps.

Step 1: Design the beam

The first step is to design the beam according to the specifications and requirements of the project. You need to determine the dimensions, shape, and reinforcement details of the beam. You can use software tools or manual calculations to design the beam. Some of the factors that affect the design are:

- The load and span of the beam

- The concrete grade and strength

- The steel grade and yield strength

- The safety factor and limit state

- The environmental conditions and exposure

Step 2: Prepare the formwork

The second step is to prepare the formwork for the beam. Formwork is a temporary structure that supports the concrete until it hardens. You need to use wooden or metal boards to make the formwork. The formwork should be strong, rigid, and accurate. Some of the steps to prepare the formwork are:

- Cut and assemble the boards according to the beam dimensions

- Fix the boards with nails or clamps

- Apply oil or grease on the inner surface of the formwork to prevent sticking

- Place spacers or supports to maintain the gap between the formwork and the reinforcement

- Align and level the formwork with a spirit level or plumb bob

Step 3: Place the reinforcement

The third step is to place the reinforcement inside the formwork. Reinforcement is a steel mesh or bars that provide tensile strength and ductility to the concrete. You need to use deformed or ribbed bars for better bonding with the concrete. Some of the steps to place the reinforcement are:

- Cut and bend the bars according to the design details

- Tie the bars with wire or clips at regular intervals

- Place the bars in horizontal and vertical layers as per the design

- Provide hooks or bends at the ends of the bars for anchorage

- Cover the bars with concrete cover blocks or spacers to protect them from corrosion

Step 4: Pour and cure the concrete

The final step is to pour and cure the concrete in the formwork. Concrete is a mixture of cement, sand, aggregate, and water that hardens into a solid mass. You need to use ready-mix concrete or mix it on site according to the design mix. Some of the steps to pour and cure the concrete are:

- Transport and place the concrete in layers using a bucket or pump

- Compact and level the concrete using a vibrator or trowel

- Finish and smoothen the surface of the concrete using a float or brush

- Cover and moisten the concrete with wet cloth or plastic sheet for at least 7 days

- Remove the formwork after 14 days or when the concrete attains sufficient strength

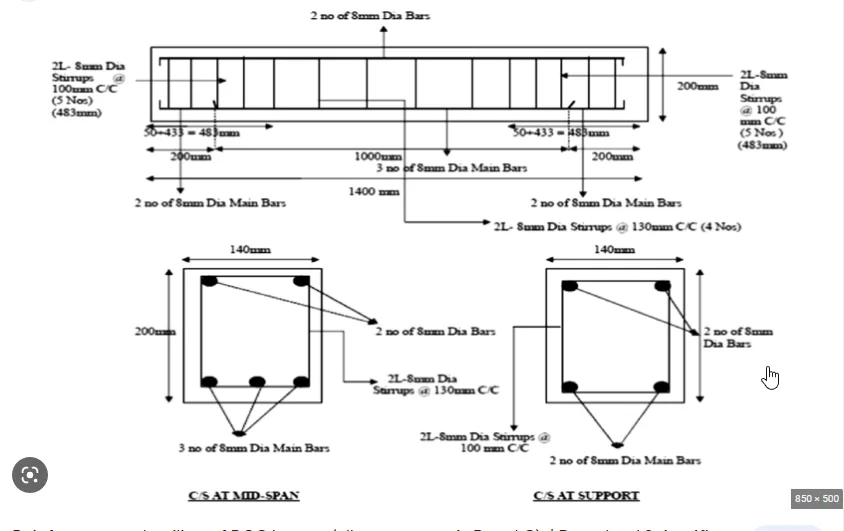

When designing a RCC beam, the proper size of the beam and the reinforcement necessary to withstand the loads and bending moments must be determined. Calculating the effective span, depth, width, moment of inertia, and necessary reinforcement, as well as checking for shear, deflection, cracking, and general stability, are all steps in the design process.

In the next article we will discuss the basic steps involved in the design of a RCC beam followed by an example.

By mastering the concepts and techniques surrounding RCC beams, civil engineers can navigate the complexities of structural design with confidence, delivering innovative and sustainable solutions that shape the built environment.