Steel possesses versatile mechanical, physical and chemical properties. properties of steel can be tailorable to meet diverse infrastructure demands.

Optimizing steel selection requires understanding critical performance factors related to composition, processing history and microstructure.

Civil engineering steel is a versatile and reliable construction material widely used in various infrastructure projects, such as bridges, buildings, and towers.

Steel’s high strength-to-weight ratio, ductility, and durability make it an ideal choice for challenging engineering applications. It can withstand significant loads, resist seismic activity, and endure harsh environmental conditions.

Civil engineering steel comes in a variety of grades and shapes, including beams, columns, plates, and reinforcing bars, allowing for flexible design options and efficient construction processes.

The use of steel in civil engineering has revolutionized the way we build, enabling the creation of taller, longer, and more complex structures.

Advancements in steel manufacturing and fabrication techniques have further enhanced its performance and sustainability, with innovations such as high-strength low-alloy (HSLA) steels and corrosion-resistant coatings.

As the demand for resilient and sustainable infrastructure grows, civil engineering steel continues to play a crucial role in shaping our built environment, offering strength, reliability, and endless possibilities for modern construction.

This article outlines key steel properties and modification principles guiding fit-for-purpose material choices.

Properties of Steel in Civil Engineering

Steel is a fundamental material in civil engineering, offering a wide range of properties that make it suitable for various construction applications.

One of the most significant properties of steel is its high strength-to-weight ratio, which allows for the creation of lightweight yet robust structures.

This characteristic is particularly important in the design of tall buildings, long-span bridges, and other large-scale projects where structural efficiency is crucial. Another essential property of steel is its ductility, which enables it to undergo significant deformation before failure, providing a safety margin in case of overloading or unexpected events.

Steel’s elasticity also allows it to return to its original shape after the removal of loads, ensuring the longevity and resilience of structures.

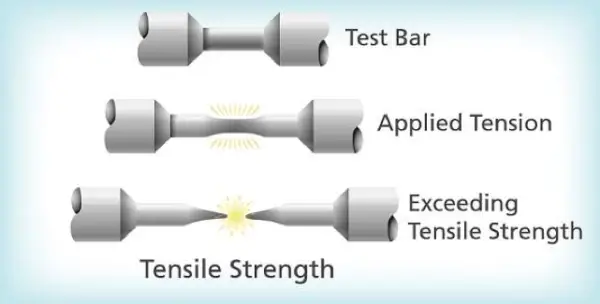

Additionally, steel possesses excellent tensile strength, making it ideal for applications that require resistance to pulling forces, such as in the construction of suspension bridges and cable-stayed structures.

Steel’s versatility, durability, and reliability make it a go-to material for civil engineers, enabling the creation of innovative and sustainable infrastructure that stands the test of time.

Mild Steel Engineering Properties

Mild steel, also known as low-carbon steel, is a widely used material in civil engineering due to its versatile properties and cost-effectiveness.

With a carbon content of up to 0.3%, mild steel offers a balanced combination of strength, ductility, and workability. One of the key properties of mild steel is its relatively low tensile strength compared to high-carbon steels, typically ranging from 250 to 500 MPa.

However, this lower strength is compensated by its excellent ductility, allowing for easy forming, bending, and welding without the risk of cracking or fracturing.

Mild steel’s good machinability enables the production of various shapes and sizes, making it suitable for a wide range of applications in construction, such as structural frames, beams, columns, and reinforcing bars.

Additionally, mild steel has a high yield strength-to-tensile strength ratio, ensuring a sufficient safety margin before the material reaches its plastic deformation stage.

While mild steel may not be the strongest option available, its versatility, affordability, and ease of use make it a popular choice for many civil engineering projects, particularly in situations where moderate strength and high workability are required.

Mechanical Properties of Steel – Types

Steels achieve wide-ranging mechanical properties via controlled compositions and treatments influencing microstructures. Major alloy types include:

- Carbon steels – Containing up to 2% carbon plus manganese and silicon additions

- Alloy steels – Adding chromium, nickel, molybdenum for enhanced properties

- Stainless steels – High chromium and corrosion resistance

- Tool steels – Very hard for cutting tools via abundant tungsten, molybdenum carbides

These different steel families provide graduated strength, hardness, toughness and ductility as needed – from structural framing to pipelines, reactors, engines, and machining tools.

Physical Properties of Steel Composition

Key physical attributes stem from chemical makeup and atomic bonding.

For structural design, density defines member weight and stiffness, while thermal expansion coefficients dictate tolerable temperature ranges to avoid buckling or separation.

Electrical resistivity affects pipeline current induction protection against corrosion.

Specific compositions also attain special magnetic or radiation-shielding properties.

Identifying critical physical characteristics ensures steel suits its installation.

Effect of Heat Treatment on Properties of steel

Heating and cooling treatments develop desired property combinations by modifying microstructures:

- Quenching – Rapid cooling fixes hardest martensite phase

- Tempering – Subsequent reheating restores some ductility

- Normalization – Slow cooling resets uniform grain sizes

- Annealing – Lowers hardness and brittleness

Well-designed thermal processing sequences boost strength, toughness, durability and more to meet application needs from structural frames to vehicle bodies and industrial equipment.

Comparing Properties of steel By Grade

Standard specifications detail composition ranges, processing methods, and testing procedures to ensure reliable mechanical properties across production batches for a grade designation. Minimum acceptable values define:

- Yield strength

- Tensile strength

- Elongation at break

- Impact resistance

Checking certified test reports verifies properties, facilitating grade substitutions if specifications align.

Guide to Properties of steel for Selection

Matching material attributes to loading, environmental and durability demands of an application requires assessing:

- Strength – Yields desired safety margins

- Fracture toughness – Resilience against crack propagation

- Fatigue rating – Endurable cycles without failure

- Corrosion resistance – Durability in external conditions over decades

Detailed steel selection guides cover chemical compositions, processing methods and property test results by grade assisting engineers to optimize selections.

How to Modify Properties of steel With Processing

Enhancing steel properties beyond composition adjustments needs controlled heating and working:

- Alloying additions – Elements like nickel and chromium improve properties

- Heat treatment – Phases precipitation and grain sizes manipulation via thermal cycles

- Mechanical working – Rolling, forging refine grains and introduce strain hardening

- Coatings – Enhance corrosion and wear resistance

Combining these techniques allows “tuning” microstructures to achieve strength, toughness, durability targets.

Factors Influencing Material Properties of steel

- Chemical composition – Carbon and alloying elements

- Production method – Basic oxygen or electric arc furnace smelting

- Deoxidation practice – Calcium treatment of residual oxygen effects

- Continuous casting – Rapid solidification structure control

- Rolling – Mechanical working and heat processing

- Product forms – Plate, sheet, bar, pipe, wire variations

Interactions between these factors determine resultant steel microstructure and associated properties.

Testing Methods for Steel Properties

Laboratory analyses definitively measure mechanical, physical and chemical properties:

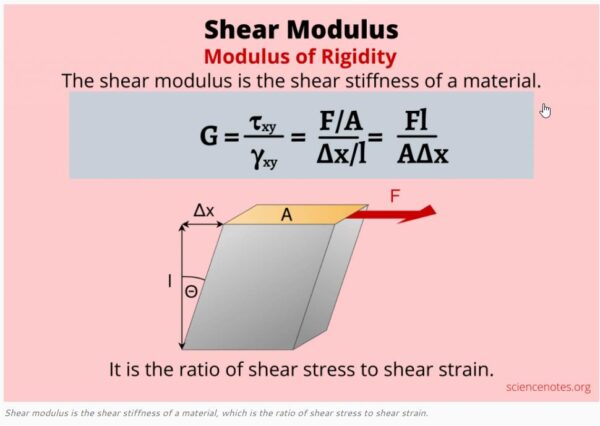

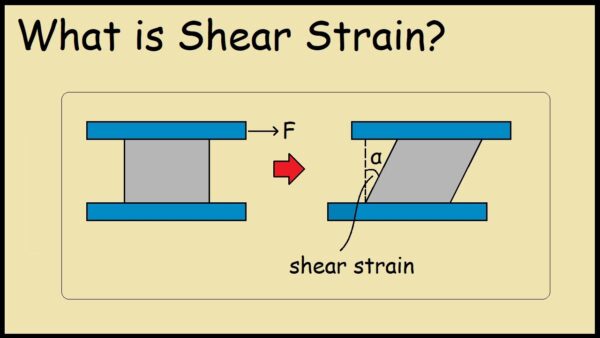

- Tensile tests – Strength, ductility, Young’s modulus

- Charpy impact – Brittleness, toughness, fracture behavior

- Hardness tests – Indentation resistance indicating machining response

- Fatigue assessments – Endurance limit through cyclic stressing

- Density measurement – Chemical composition checks

Data-driven standards development and quality assurance relies on steel testing rigorously characterizing material performance.

Impact of Alloying Elements on Steel Properties

Strategic alloying additions transform simple iron into sophisticated steels:

- Manganese – Stronger mild steel with sulfur neutralization

- Nickel – Toughening austenite stabilizer

- Chromium – Corrosion resistant, hardenability booster

- Molybdenum – High strength, creep resistant enhancer

- Vanadium, niobium – Ultrafine carbide formers for precipitate strengthening

Optimized compositions balance hardenability, weldability, corrosion resistance and cost.

Modeling Steel Properties from Microstructure

Relating chemical makeup and processing history to resultant microstructure provides models predicting steel properties:

- Quantitative metallography – Image analysis determining phases

- Computation thermodynamics – Equilibrium cooling transformations simulations

- Process modeling – Heat transfer, deformation physics reproductions

In silico modeling now suggests new tailored grades and treatments for custom property goals.

Understanding interdependent influences on achievable property combinations enables engineers to select optimized steel compositions and processing for structural reliability over extended service lives.

This covers the breadth of factors determining steel microstructures conferring desired strength, toughness, durability and additional properties – from production through testing and computational modeling.

Proper characterization and quality assurance ensures high-performance steel infrastructure.