The ultimate tensile strength (UTS) of a material defines its maximum resistance to breakage from applied tensile loads.

When analyzing materials for load-bearing structural applications, one of the most crucial mechanical properties to evaluate is the ultimate tensile strength (UTS).

UTS quantifies the maximum stress a solid can withstand under tension before fracturing and defines its axial failure limit.

By accurately measuring a material’s UTS through standardized tensile testing procedures, engineers gain insight into how durable, damage-tolerant, and reliable it will prove when experiencing real-world tensile loads.

Compared to the related yield strength value signaling permanent plastic deformation, UTS denotes outright component failure.

What is Ultimate Tensile Strength?

Ultimate tensile strength (UTS) refers to the maximum stress a material can withstand when subjected to uniaxial tensile forces before it fractures.

It quantifies the stress at the point of failure when the material breaks rather than yielding. UTS indicates how rigid and damage-tolerant a solid is when under axial stretching loads.

UTS provides the ultimate limit to properly engineer load-bearing structures like bridges, pressure vessels, or components like fasteners, gears and wires.

Deriving the Formula for Ultimate Tensile Strength

The basic UTS formula from fundamental solid mechanics is:

UTS = Fmax/A0

Where:

UTS = Ultimate tensile strength (MPa or psi)

Fmax = Maximum axial load force applied at failure (N or lb)

A0 = Original cross-sectional area perpendicular to load (m2 or in2)

This calculates stress as force per unit area when fracture occurs for the test specimen.

Steps to Determine UTS with Tensile Testing

Tensile testing is performed to experimentally measure the UTS of materials like metals, composites, polymers etc.

The method involves:

- Securing a sample between grips in a tensile test machine

- Gradually applying uniaxial tensile force until rupture

- Recording the maximum tensile load reached

- Measuring original cross-sectional area

- Calculating UTS using formula above

This returns the final stress point in MPa, psi or GPa – quantifying how much tensile load per area the material tolerated prior to failure.

Controlled testing per ASTM standards ensures uniform reproducible results for reliable data.

Analyzing Stress-Strain Curves from Tensile Tests

Tensile testing rigs automatically plot full stress-strain curves showing material response:

Key points provide valuable information:

- Proportional limit – Linear elastic behavior transitions to plastic

- Yield point – Onset of permanent deformation

- Ultimate strength – Maximum stress reached before fracture

- Fracture point – Final failure after some necking strain

Understanding how materials stretch and eventually snap based on these curves allows durable engineering design.

Key Differences: UTS vs Yield Strength

It is important distinguish between:

- Ultimate tensile strength – Maximum stress during elastic/plastic deformation

- Yield strength – Stress causing initial permanent deformation

While UTS denotes complete failure limit, yield strength signals the start of non-reversible changes from ductile stretching. Their relation enables safe operating design limits.

Typically, UTS exceeds yield strength for ductile metals while they are similar levels for stiff ceramics.

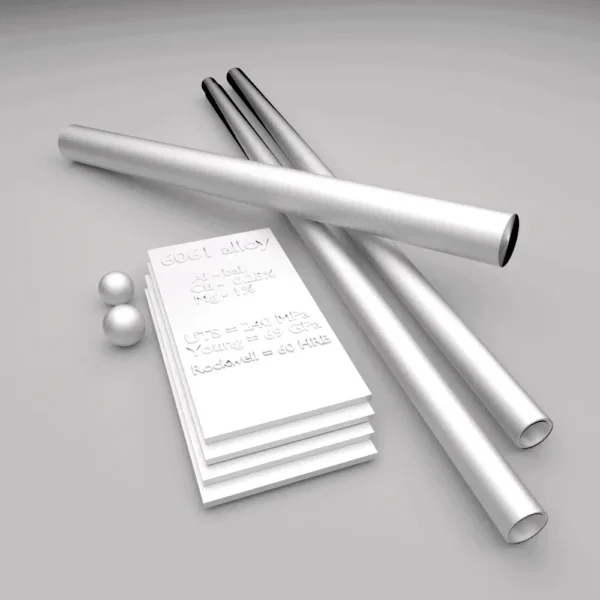

Factors Influencing Ultimate Tensile Strength

Many aspects impact the UTS capability for materials including:

- Alloy composition (carbon, chromium, nickel etc.)

- Manufacturing method (casting, rolling, forging etc.)

- Heat treatment process parameters

- Prior cold mechanical working levels

- Presence of defects like voids or impurities

- Grain size and phase morphologies

Understanding interactions between these factors allows engineers to tailor UTS to application requirements.

Approaches for Improving UTS in Materials

Common methods for increasing metal strength include:

- Alloying elements like niobium, titanium, and vanadium

- Reducing crystal grain size through specialized heat treatment

- Introducing cold working deformation before aging

- Powder consolidation processes for refined porosity and consistency

Careful microstructure and defect control enables cutting-edge high-strength materials with UTS past 2.5 GPa.

Hardness and UTS Correlation

While distinct mechanical properties, hardness and UTS often have a strong positive correlation

Increasing hardness values from optimized precipitation strengthening or finer grains frequently improves associated UTS capability.

But hardness-UTS ratios can change based on work hardening or internal damages. Direct UTS evaluation remains vital.

Frequently Asked Questions – Ultimate Tensile Strength

why is ultimate Tensile strength important?

Ultimate tensile strength (or just tensile strength for short) is an important property of materials to determine their mechanical performance. It is the ability of a material to resist tearing due to tension. This parameter applies to all types of materials such as wires, ropes, metal beams, etc.

how is ultimate tensile strength calculated?

The ultimate tensile strength of a material can be found by dividing the force required to break a material by its original cross-sectional area.

ultimate tensile strength (U.T.S.), σ max = P max /A 0 , where P max = maximum load, A 0 = original cross sectional area.

What factors affect a material’s ultimate tensile strength?

The main factors that affect UTS are:

Composition/alloy elements added

Heat treatment processes

Production method (casting, rolling, forming, etc.)

Presence of defects or impurities

Strain hardening and prior deformation

Temperature

High UTS Steels Through Precision Thermomechanics

State-of-the-art steels like maraging steels and high-performance HSLA alloys leverage computational materials science and advanced production methods to achieve exceptional strength.

Carefully balanced thermomechanical processing controls microstructures granting UTS past 2500 MPa without fragility. Tailored nanoscale precipitates and dislocations enable dislocation glide resistance and high tensile limits.

Such steels find increasing deployment in aerospace, sporting goods, and military vehicles.

In summary, understanding UTS helps engineer durable components and prevents premature structural failures.