Traditional aggregates can be replaced by a number of other materials while making concrete.

Aggregates are one of the main components of concrete, which is the most widely used construction material in the world.

However, the extraction and consumption of natural aggregates, such as river sand and gravel, have negative impacts on the environment and human health. Therefore, there is a need to find alternative sources of aggregates that are more sustainable and eco-friendly.

In this blog post, we will introduce some of the alternative materials that can be used as aggregates in concrete production. These alternatives include:

- Fibrous concrete or papercrete: This is a type of concrete that uses waste paper or paper pulp as a partial or total replacement of coarse aggregate. Papercrete has low density, good thermal insulation, and fire resistance properties. It can be used for low-cost housing and non-structural applications.

- Plastic waste: This is a type of concrete that uses plastic waste, such as bottles, bags, or containers, as a partial or total replacement of coarse or fine aggregate. Plastic waste concrete has lower density, higher ductility, and better resistance to cracking than conventional concrete. It can be used for lightweight structures and pavements.

- Glasscrete or post-consumer glass: This is a type of concrete that uses crushed glass from discarded bottles or windows as a partial or total replacement of fine aggregate. Glasscrete has higher strength, durability, and aesthetic appeal than conventional concrete. It can be used for decorative and architectural purposes.

- Expanded polystyrene concrete: This is a type of concrete that uses expanded polystyrene (EPS) beads as a partial or total replacement of coarse aggregate. EPS concrete has very low density, high thermal insulation, and good sound absorption properties. It can be used for insulation and filling applications.

- Crushed rubber: This is a type of concrete that uses crushed rubber from end-of-life tires as a partial or total replacement of coarse aggregate. Rubber concrete has lower density, higher toughness, and better energy absorption than conventional concrete. It can be used for impact-resistant structures and pavements.

- Coconut shell: This is a type of concrete that uses coconut shell as a partial or total replacement of coarse aggregate. Coconut shell concrete has lower density, higher workability, and comparable strength to conventional concrete. It can be used for lightweight structures and rural housing.

These options are frequently used to solve particular problems or improve particular concrete qualities. Here are a few illustrations:

Lightweight Aggregates

- To lighten concrete, lightweight particles like perlite, shale, or expanded clay are utilized.

- When weight reduction is desired, like in high-rise buildings or constructions with load restrictions, this is advantageous.

- Lightweight aggregates offer a similar level of strength while lowering the concrete’s total density.

Recycled Aggregates

- Recyclable trash from building and demolition, including concrete shards or asphalt, is the source of recycled aggregates.

- To create aggregates that can be used in place of natural aggregates, these materials are crushed and treated.

- Utilizing recycled aggregates encourages sustainable practices by lowering waste production and reducing the need for new resources.

Industrial By-Products

- Concrete aggregates can sometimes be replaced in part by certain industrial byproducts.

- One additional cementitious material that can be utilized in the manufacturing of concrete is fly ash, a by-product of the burning of coal in power plants.

- It improves the concrete’s capacity to be worked, as well as its long-term performance.

Ground Granulated Blast Furnace Slag (GGBFS)

- A by-product of the iron and steel sector is GGBFS. It is produced by using steam or water to cool molten iron slag from a blast furnace.

- Concrete’s strength, durability, and resistance to chemical attacks can all be increased by using GGBFS in place of some of the cement or aggregates.

Crushed Glass

- In some concrete applications, crushed glass can be used in place of conventional aggregates.

- In addition to enabling the creation of decorative concrete surfaces, it has a distinct aesthetic appeal.

- In most cases, recycled glass is used to make crushed glass aggregates, which reduces the quantity of glass trash that ends up in landfills and improves the environment.

Aggregates used in concrete have to follow some rules. We cannot accept any type of material. Researchers tend to find an alternate aggregate which costs less during transportation and economical. Based upon their experimentation, companies come to a conclusion that if rubber or glass etc can be used instead of coarse or fine aggregate.

Rubber Aggregates

- In some situations, rubber aggregates generated from recycled tyres can replace conventional aggregates.

- They are suitable for road pavements or other constructions that need increased durability since they are frequently employed in rubberized concrete for noise reduction, vibration damping, and impact resistance.

Hempcrete

- A bio-composite called hempcrete is created by combining the inner, woody core of the hemp plant with a binder based on lime.

- When making concrete, it can be used as a lightweight aggregate. Hempcrete is an eco-friendly alternative since it has low carbon emissions, good thermal insulating qualities, and fire resistance.

Plastic Aggregates

- Traditional aggregates can be replaced by plastic aggregates derived from recovered plastics like polyethylene and polypropylene.

- These lightweight aggregates can aid in the reduction of plastic waste. Plastic aggregates are frequently employed in non-structural applications like decks, fences, and walkways.

Rice Husk Ash (RHA)

- Ash made from rice husks can be used in concrete as a partial or additional substitute for fine aggregates or as a cementitious ingredient.

- RHA uses an agricultural waste product to enhance the concrete’s workability, strength, and longevity.

Wood Chips or Sawdust

- In some non-structural applications, wood chips or sawdust can be utilized as a replacement to conventional aggregates.

- They are frequently employed in lightweight concrete or as an addition to improve the concrete’s capabilities for thermal insulation. Wood aggregates are frequently utilized in projects like landscaping, gardening, and walkway construction.

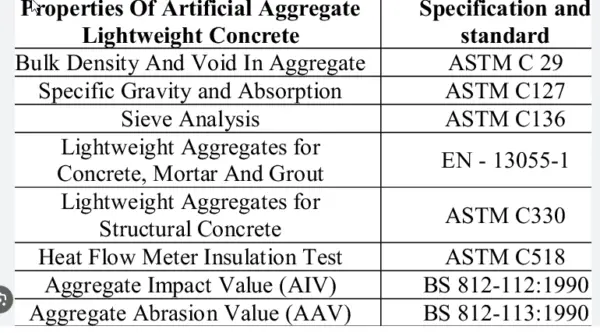

It’s significant to highlight that the employment of alternative aggregates could be subject to particular restrictions, prerequisites, or concerns. To make sure that these alternatives are appropriate and work well in practical applications, appropriate testing, compatibility studies, and adherence to pertinent regulations and standards are required.