Construction sites are hubs of activity and organization. Proper construction site management is crucial for completing projects safely, on time, and within budget. This comprehensive guide covers key aspects of managing construction sites effectively.

Construction Site Background

Construction sites are temporary locations where construction projects take place. They can range from small residential projects to massive infrastructure developments. Sites require extensive planning and oversight to ensure smooth progress.

Construction managers arrange a symphony of workers, materials, and machinery. Careful coordination minimizes delays and dangers. Adapting to changing conditions and needs is also key. Construction sites evolve rapidly, so managers must stay nimble.

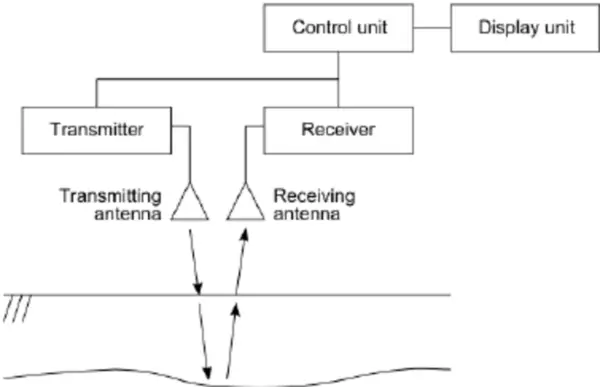

Smart construction site management harnesses technology like drones, sensors, and project management software. This technology generates invaluable data to optimize workflows. However, the fundamentals of organization and communication remain paramount.

Construction Sites in India

India’s construction industry has boomed in recent decades. Major government initiatives like the Smart Cities Mission and Housing for All have catalyzed growth. By 2025, India’s construction market is projected to become the world’s third largest.

Managing India’s unique mix of dense old cities and gleaming new developments brings challenges. Sites must be carefully laid out to minimize disruptions in crowded urban areas. Outdated building codes and lack of specialized labor hamper progress. Coordinating with local officials is also key to getting approvals and permissions.

However, India’s vast construction needs make it an extremely attractive market. With careful planning and innovation, the industry has huge potential for growth. The government’s focus on infrastructure and housing will continue driving demand.

Construction Site Design

A construction site’s layout directly impacts productivity and safety. Well-designed sites optimize traffic flow for workers, materials, and equipment. They balance space for staging, storage, and construction activities.

Sites are typically divided into zones for:

- Site access and logistics

- Materials storage and handling

- Temporary facilities like office trailers

- Active construction work areas

Carefully mapping deliveries, waste removal, and movement between zones minimizes bottlenecks. Site plans must also accommodate excavations, foundation work, and cranes or hoists.

Safety elements like warning signs, barriers, and marked walkways should be standardized across the site. Layouts may need adjustment as projects progress from initial earthworks through structure construction.

Construction Site Examples

Construction sites range from small residential builds to complex civil engineering megaprojects. Here are some notable examples:

Residential:

A typical single-family home construction site occupies a half-acre lot. It requires coordinating dozens of subcontractors. Careful scheduling and space allocation are crucial for efficiency.

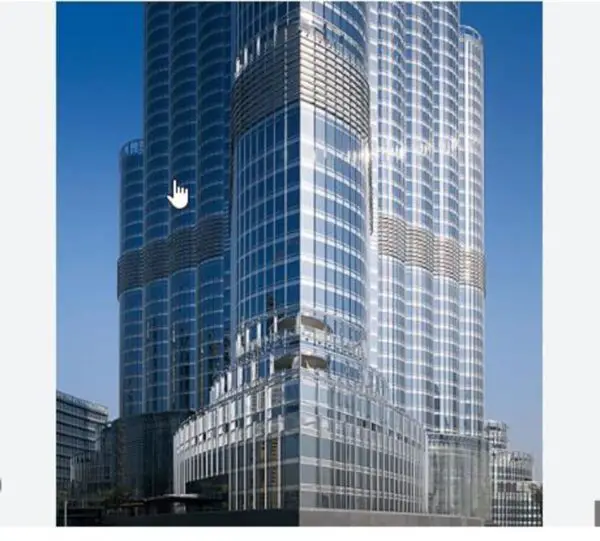

High Rise:

High rise projects require extensive vertical transport and delivery systems. Sites focus on staging materials and accessing work zones on upper floors. Perimeter protection like covered walkways prevent falling object dangers.

Airport:

Airport projects integrate construction into live travel operations. Phasing work by zones minimizes passenger disruptions. Some activities may be limited to night shifts. Sites must also accommodate aircraft needs.

Dam:

Building massive dams like China’s Three Gorges requires coordinating thousands of workers across sprawling sites. Staggering work packages and monitoring milestones are vital with enormous multi-year timelines. Sites become small cities themselves.

Types of Construction Sites

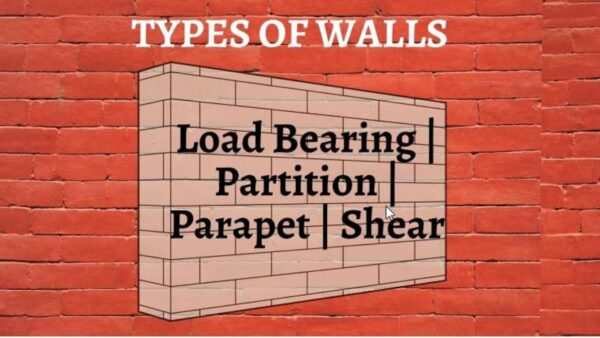

Sites can be categorized based on project type, location, and environment:

- Building Construction Sites: Commercial, residential, industrial, or institutional building projects. May involve new construction, renovations, or demolitions.

- Infrastructure Sites: Roads, bridges, railways, airports, dams, pipelines, and other civil engineering projects. Often linear sites spread across large areas.

- Rural Sites: Home or infrastructure construction in rural areas. Requires coordinating deliveries across long distances. Sites may be remote with limited access roads.

- Urban Sites: Building or redeveloping structures in crowded cities. Space constraints and disruptions to surroundings must be managed. Noise, dust, and traffic issues arise.

- Industrial Sites: Constructing facilities like factories, refineries, and power plants. Sites accommodate heavy machinery and modular components built off-site. Safety and environmental controls are critical.

- Offshore/Marine Sites: Projects like seaports, bridges, oil platforms, and wind farms located over or near water. Sites require extensive marine equipment and logistics.

Construction Site Facilities

Construction sites require extensive facilities and services to support their workforce and activities. These include:

Site Offices: Provide space for management, meetings, site plans, and record-keeping. May include staff amenities. Prefabricated trailers are commonly used.

Material Storage: Designated areas to store materials like aggregates, steel, timber safely. Proper stacking/piling prevents damage or collapse. Just-in-time deliveries reduce storage needs.

Worker Amenities: Facilities like toilets, canteens, shelters, and first aid stations for worker welfare. Required by safety regulations. Areas for changing, drying clothes, and equipment storage are also useful.

Temporary Structures: Site hoarding, barricades, scaffolding, and formwork platforms required during construction. Overhead protection platforms prevent falling object hazards.

Power and Lighting: Generator sets and temporary wiring/lights illuminate work zones. Adequate lighting improves safety and lets certain tasks continue overnight.

Construction Water: Water tanks, piping, pumps provide construction water for various needs like concrete mixing, washing, and dust control.

Waste Management: Bins, chutes, and designated zones to collect and segregate construction/demolition waste. Helps efficiently clear and dispose of scrap.

Construction Industry Overview

The global construction industry is worth over $10 trillion and accounts for 13% of the world GDP. The sector is a major source of jobs, employing 7-10% of the global workforce.

Construction has rebounded strongly after the pandemic dip. But the industry also faces challenges like skills shortages, supply chain disruptions, and increased environmental regulations.

Adopting modern techniques like offsite modular construction, digital workflows, and increased automation will be key to the industry’s future. Sustainability concerns are also driving changes in materials, energy use, and building lifetime carbon footprint.

Governments play a crucial role through investments, incentives, and policy reforms that can accelerate innovation. But improving site management practices is equally vital for translating potential into real-world gains in cost, time, quality and safety.

The key aspects of construction site management is proper planning, layout, coordination and monitoring are essential for smooth functioning and successful finishing of the project. Adapting sites and systems to evolving needs during projects is also crucial.