One of the most frequently used building materials worldwide is cement. It is a crucial component of plaster, concrete, mortar, and other building materials.

But not all cement is made equally. The applicability of various cement kinds for different applications depends on their distinct performance and property characteristics.

As a result, testing cement is crucial before utilizing it in any building project. You can test cement to find out about its strength, durability, and compatibility with other materials.

Also, testing can assist you in finding any flaws or issues that might appear while producing, storing, or transporting cement.

Several tests are conducted to know the physical and chemical properties of cement.

In order to know the quality, strength and rate of setting suitable to the demands of the work various tests are conducted on cement which include field and laboratory tests.

In this blog, we are going to discuss various field tests conducted on cement to ascertain the basic qualifications which are mentioned above.

Field Tests on Cement

Cement field tests are quick and easy ways to assess the quality of cement at a construction site. Without any specialized tools or a lab, anyone can perform these.

These field tests can be helpful in evaluating cement quality and making sure it complies with the criteria needed for usage in construction.

It is crucial to keep in mind, though, that these exams might not be as precise or dependable as laboratory examinations.

Colour

Cement should be a consistent, greenish-gray tint. Any colour variation could be a sign of adulteration or improper storage practices.

Date of Packaging

To make sure that the cement is not more than 90 days old from the date of manufacture, check the date of packing on the cement bag.

Due to moisture absorption and hydration, cement gradually loses its quality and strength over time.

Presence of lumps

Hard lumps that form when moisture from the air is absorbed should not be present in cement. Lumpy cement indicates that it has partially set and degraded in quality.

Smoothness

When cement is stroked between the fingertips, it should feel smooth. It’s been adulterated with sand or other contaminants if it feels gritty or rough.

Temperature

When inserted into the bag or handled, the cement should feel cool. If the cement is warm to the touch or hot to the touch, a hydration reaction has occurred inside the bag and the cement has degraded.

Float test

A small amount of cement should initially float on water before sinking. If it sinks right away, the cement is tainted or has lost its ability to hold in air.

Smell Test

An earthy scent should not be present in a thin cement paste made with water. An earthy odour is a sign that the cement has been adulterated with too much clay or silt.

Glass Plate Test

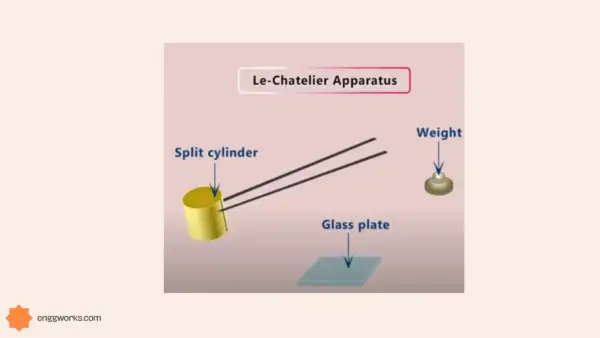

On a glass plate, a thick cement and water paste should be applied, and it should be submerged in water for 24 hours. It ought to harden and not break. Cracks show that the cement has expanded excessively as a result of free lime or magnesia.

Block Test

Three days should pass after placing a (25mm x 25mm x 200mm) cement block in water. It should then be supported 150mm apart, with a 15kg weight evenly distributed over it. If there are no indications of failure, the cement is sound.

These cement field tests can aid in determining the site’s quality of cement and help prevent the use of shoddy or outdated cement for concrete construction. These should be confirmed by laboratory testing for greater accuracy and dependability because they are not yet conclusive.