Septic tanks are a crucial component of decentralized wastewater management systems. Proper septic tank design is essential to ensure effective treatment of sewage from individual households or buildings before discharge or reuse.

Septic Tank Design: An Introduction

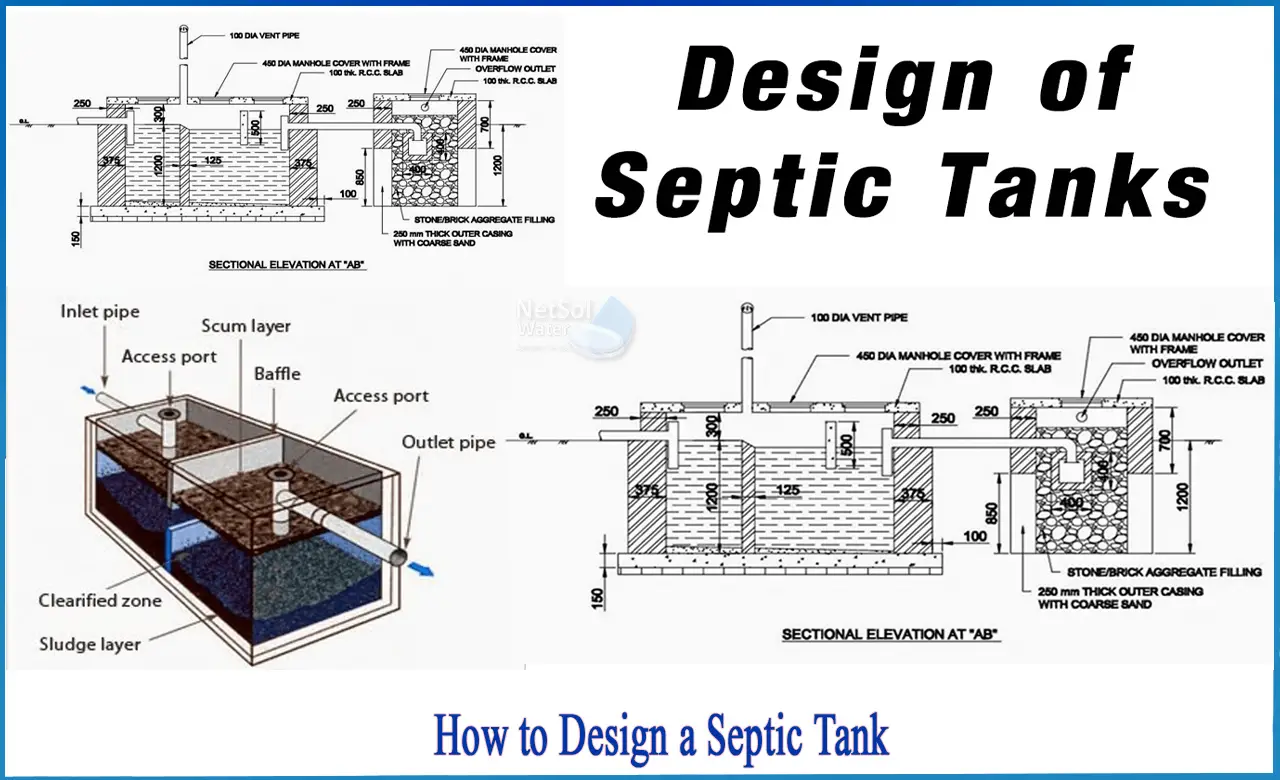

Septic tanks offer a preliminary treatment of sewage before final disposal. The sewage is held in these tanks for a prescribed period, allowing suspended solids to settle down. The settled sludge and supernatant liquor undergo anaerobic digestion, significantly reducing the sludge volume and organic matter in the liquid.

IS : 2470 (PART 1) – 1985 provides recommendations for the design, layout, construction, and maintenance of septic tanks, applicable to houses, flats, residential colonies, hostels, and boarding schools with up to 300 users. In unsewered areas, every house should have a septic tank for sewage treatment, with the effluent receiving secondary treatment in a biological filter, up-flow anaerobic filter, on land, or in a subsurface disposal system.

Proper design, construction, and maintenance of septic tanks are crucial for effective sewage treatment. This introduction aims to provide guidance to local bodies, public works departments, and others engaged in this field, ensuring the implementation of efficient septic tank systems.

What is a Septic Tank? – Purpose and Importance

A septic tank is an underground chamber made of concrete, fiberglass or plastic that collects and treats sewage from a building or facility not connected to a sewerage network.

Key functions of a septic tank:

- Collects all wastewater from toilets, sinks, washing machines etc.

- Separates settleable and floating solids from the liquid.

- Provides preliminary treatment by anaerobic digestion of organic matter.

- Reduces BOD, TSS and pathogenic organisms in sewage.

- Removes debris, grit, grease and scum from effluent.

- Distributes partially treated effluent for further treatment.

Well-designed septic tanks are critical for public health protection by ensuring proper sanitation in areas lacking centralized sewerage infrastructure.

Septic Tank Size Calculations

Septic tank capacity depends on the number of users, wastewater generation and retention time required. The main sizing parameters are:

- Number of users – Consider residential occupancy or number of employees/visitors for commercial buildings. Also account for any future expansion.

- Wastewater flow rate – Use typical values of sewage generation rates per user. Varies from 100-200 liters/person/day based on water supply.

- Retention time – 1-3 days retention time is ideal. Provides sufficient hydraulic retention time for settling and anaerobic digestion.

- Sludge storage – Bottom one-third of tank height reserved for accumulated sludge.

- Scum storage – Top one-tenth for floating scum layer.

Calculate the total volume based on these factors. Multiple compartments can split the volume to improve settling.

Septic Tank Dimensions

Typical dimensions for septic tanks are:

- Length to width ratio of 2:1 to 3:1. Common sizes are 8×4 ft, 6×3 ft or 4×2 ft.

- Depth of 6-9 ft. Deeper tanks may require access risers.

- Minimum of two compartments. The first 2/3rd for primary settling and digestion.

- Inlet and outlet at opposite ends with inlet tee or baffle.

- Rectangular cross-section.

Sizing should meet wastewater flow demands while ensuring adequate hydraulic retention time.

Septic Tank Layout and Plans

Septic tank location should:

- Be easily accessible for cleaning and maintenance.

- Maintain distance from water supply sources as per regulations.

- Have good drainage with sloped inlet pipe and positive outlet head.

- Not be under driveways, parking areas or other structures.

Components of a septic tank plan:

- Detailed dimensions and structural design.

- Inlet, outlet, manholes, partitions and all openings.

- Depth of embedment and ground cover.

- Level of inlet/outlet pipes and lids.

- Positioning on site meeting clearance requirements.

Septic Tank Structural Design

Septic tanks are typically designed as reinforced concrete tanks suitable for underground conditions:

- Concrete mix – Minimum grade of M20 with maximum aggregate size of 20mm is used.

- Reinforcement – 10mm to 16mm bars at 150mm to 300mm spacing for walls and slabs. Higher steel density at openings.

- Wall and slab thickness – Minimum of 150mm thick reinforced concrete. Increased at deeper depths.

- Waterproofing – External bituminous/epoxy coating prevents groundwater ingress.

- Connections – Risers extended to surface have reinforced collars.

- Backfilling – Well compacted granular fill surrounds the tank.

Septic Tank Construction Specifications

- Cast-in-situ or precast concrete construction. Precast tanks need proper joint sealing.

- Concrete work follows IS code specifications – proper formwork, placement, compacting, curing etc.

- Water tightness testing after curing – tank filled with water for 24 hours.

- Backfilling in layers after waterproofing external surfaces.

- Inlet and outlet pipes have minimum 1% slope and firmly sealed joints.

- Risers fitted with covers at the top. Ventilation pipes installed.

Septic Tank Materials Selection

- Concrete – Most common and economical option. Durable and structurally sound.

- Fiberglass – Lightweight and corrosion resistant. Need proper support.

- Plastic/PE – Cheaper but prone to damage and have shorter life than concrete.

- Steel – Not preferred as prone to corrosion in subsurface conditions.

- Brick/stone masonry – Rarely used as prone to leakage and structural issues.

Concrete is the material of choice for septic tanks due to its strength, stability and longevity.

Septic Tank Installation Guide

Proper installation procedures are vital for a fully functional septic tank:

- Excavate pit to required depth and dimensions with uniform flat bottom.

- Place a layer of crushed stone below the tank for foundation.

- Lower tank into pit using lifting hooks or slings.

- Ensure inlet/outlet orientation as per design.

- Make watertight connections to inlet and outlet pipes.

- Backfill properly compacted layers of soil around tank.

- Avoid any damage to tank during backfilling.

- Check levels and slope of inlet/outlet pipes.

- Install manhole covers and ventilation at specified positions.

Septic Tank Inspection and Maintenance

- Annual inspections to check sludge/scum levels, leaks, condition of filters, manifold etc.

- Measure sludge and scum to determine tank pumping frequency.

- Desludge tank when sludge volume exceeds 40% of liquid depth.

- Clean outlet filter and screen. Check soak pit for clogging.

- Regular maintenance extends life and prevents premature failures.

- Keep accessibility for inspections and cleaning.

- Maintain records of inspection data.

Septic Tank Upgrading and Repairs

Some upgrades can optimize septic tanks:

- Adding aeration unit or bio-filter for advanced treatment.

- Installing an effluent filter at outlet to prevent solids carryover.

- Increasing capacity by adding compartments.

Common repairs include:

- Patching leaks using waterproof sealants.

- Replacing damaged or defective covers and vents.

- Repairing inlet/outlet structures.

- Fixing any broken or cracked structural components.

Upgrades enhance treatment capacity while repairs restore structural integrity and performance.

Septic Tank Design Codes and Standards

Key design standards and guidelines:

- EPA Onsite Wastewater Treatment Systems Manual

- EN 12566 – Small wastewater treatment systems

- AS NZS 1547 – On-site domestic wastewater management

- IS 2470 – Septic tank standards

- ASTM C1613 – Standard for precast concrete septic tanks

Compliance with relevant codes ensures septic tanks are designed and built to appropriate standards for safety and performance.

Conclusion

A well-engineered septic tank with robust structural design, appropriate sizing, layout, material selection and proper installation is crucial for effective decentralized wastewater management.

Routine inspection and maintenance along with any required upgrades or repairs ensures optimal functioning for the full lifespan. Adhering to design codes and regulations is essential to protect public health while meeting effluent standards.