Concrete is the backbone of modern construction, and its strength, durability, and performance depend on the concrete mix ratio used.

A proper mix of cement, sand, gravel, and water decides whether your structure can withstand pressure, weather, and time.

Understanding the proportions is crucial, whether you’re using a nominal mix ratio for small projects or a 3500 psi concrete mix ratio for strong foundations.

By the end, you will know what the standard ratios are for different applications, how to calculate the correct quantity of each ingredient, and comparisons between 3000 psi, 3500 psi, 4000 psi, and beyond.

What is a concrete mix ratio?

A concrete mix ratio is simply the proportion of cement, sand, gravel (coarse aggregates), and water combined to produce concrete of desired strength. Expressed as 1:2:4 (cement:sand:gravel), it helps engineers calculate the concrete mix design ratio needed for safe and long-lasting structures.

For example:

- 1:2:4 = 1 part cement, 2 parts sand, and 4 parts gravel, with water added for workability.

The cement mix ratio affects strength, setting time, and durability. A lower water-to-cement ratio increases strength but reduces workability.

Why Mix Ratios Matter

The concrete mix ratio and strength are directly connected. If the ratio is inaccurate, a structure may crack, fail prematurely, or be over-designed (too costly). A balanced ratio provides:

- High compressive strength

- Good workability during placement

- Better durability in varying weather

- Long service life with minimal maintenance

Contractors calculate mix ratios for concrete strength using design codes (IS 456 in India, ACI in the US).

Nominal Mix Ratio vs Design Mix Ratio

There are two major categories of concrete mix ratios:

- Nominal Mix Ratio

This mix ratio is commonly used in small projects or non-engineering works such as residential flooring. Examples: 1:2:4 or 1:3:6. This method is traditionally used for projects that require concrete grades of up to M20.

Example:Nominal mix concrete ratio for cement:1 cement: 2 sands: 4 gravels. - Design Mix Ratio

Lab tests calculate the design mix ratio scientifically, ensuring the use of exact quantities for large projects. The design mix ratio is utilized in concrete mixing ratio tables for column and beam structures, specifically for higher grades such as M25, M30, and M40.

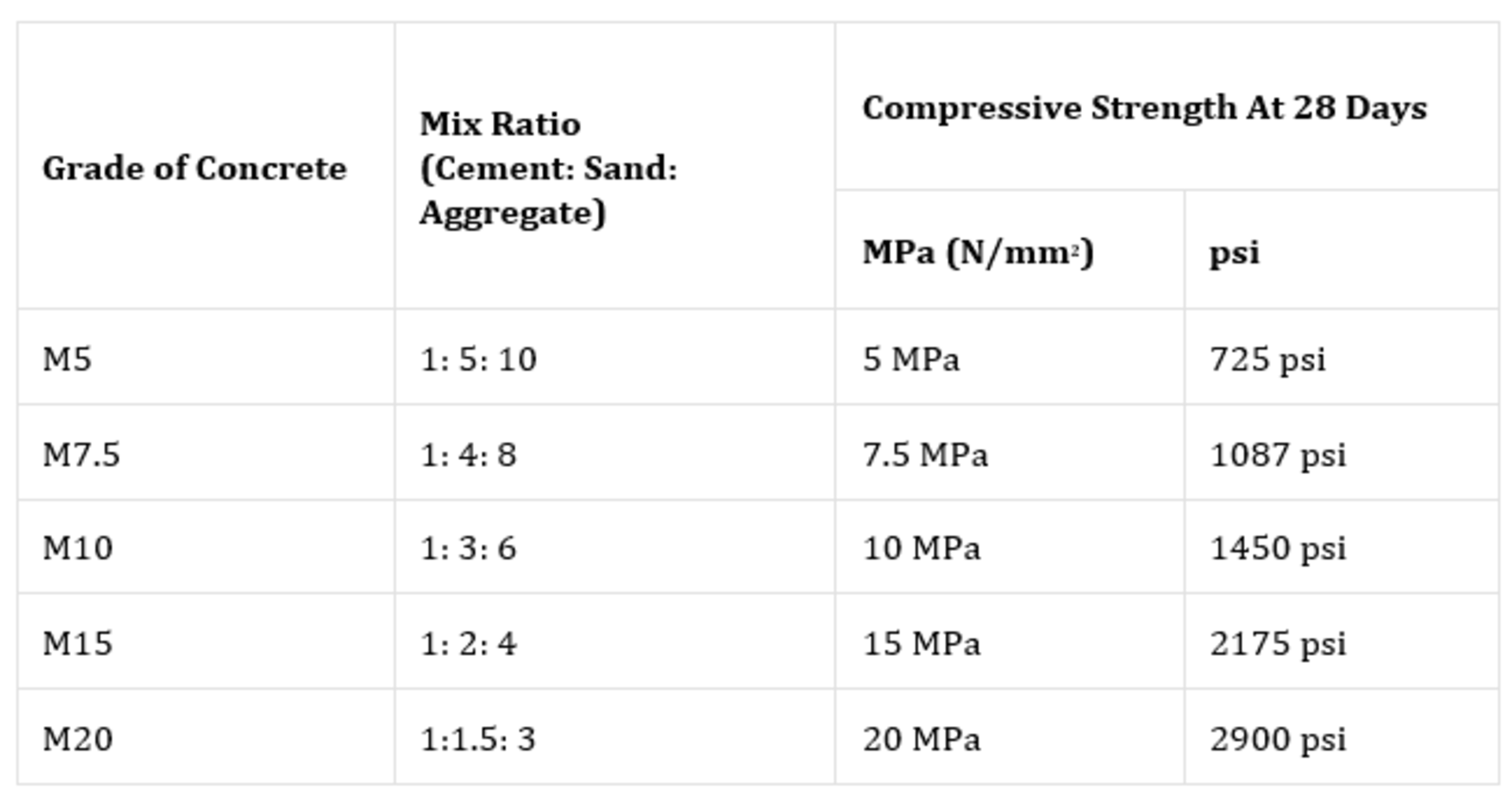

Common Standard Concrete Mix Ratios (Nominal)

- 1:5:10 → For lean concrete, filler under floors

- 1:4:8 → For sub-base layers and low-strength uses

- 1:3:6 → For foundations without reinforcement

- 1:2:4 → For reinforced slabs, beams, and columns

These are traditional standard ratios for common works where high compressive strength is not critical.

Understanding PSI in Concrete Mix

In the US, concrete strength is measured in psi (pounds per square inch). For example:

- The mix ratios of 3000 psi and 3500 psi are used in residential foundations.

- 3500, 4000, and 4500 write the ratios of the amount; these indicate how much cement, sand, and gravel proportion is needed to achieve strength.

- Bridges, heavy-duty pavements, and high-rise buildings use the 6000 psi concrete mix ratio.

The ratio of psi proportions for housing ranges between 3000 and 4000 psi, depending on soil conditions. Many home projects rely on a 3500 psi mix ratio for strength and affordability.

3000 vs 3500 PSI Concrete Mix Ratio

- The M20, or 3000 psi, concrete mix typically follows a ratio of 1:1.5:3 (cement:sand:gravel) and is commonly used in driveways and residential slab construction.

- The 3500 psi concrete mix ratio is typically 1:2:3, making it stronger and more durable, which makes it ideal for footings, basement walls, and columns.

This comparison (M20 vs 3000 psi) illustrates how the naming differs globally, but the proportions remain similar.

3500 PSI Class and High-Strength Mixes

A 3500 psi class concrete mix ensures reliable performance in reinforced columns, beams, footings, and retaining walls. Moving higher:

- The 4000 psi concrete mix ratio is suitable for pavement floor slabs that will support heavy loads.

- 4500 and 5500 concrete vs 3500: Higher psi mixes are denser, more durable, and resist chemical/weather damage much better.

When deciding between 5500 concrete vs. 3500 concrete, note that 5500 psi is recommended for high-rise or industrial projects, while 3500 psi suits residential.

High-Strength Concrete Mix Ratio

For high-strength mix concrete ratios, higher cement content and lower water-cement ratios are used.

- What is the high-strength mix concrete ratio?

The typical high-strength mix concrete ratio is 1:1:2, and it includes additives like silica fume or fly ash to achieve a strength of over 6000 psi. - High-psi concrete proportions (e.g., 6000 psi concrete mix ratio) require strict quality control and precise measurement.

- High-strength concrete mix ratios are vital for dams, bridges, towers, and high-rise structures.

Concrete Mix Ratio & Footings

One common question is, “What are the concrete mix ratios for footings that include abutment rebar?”

Standard footing concrete uses ratios like

- 1:2:4 or 1:1.5:3 (3500 psi mix ratio).

When reinforcement (rebar) is included, engineers often choose a high-strength concrete mix design ratio like M25 or a 3500 psi class for durability at abutments and foundations.

Column and Beam Structure Concrete Mixing Ratio Table

Below is a simple column and beam structure concrete mixing ratio table of cement, sand, gravel, and water:

| Structure Component | Mix Ratio (C:S:G) | Typical Strength (psi) |

|---|---|---|

| Lean Concrete Base | 1:4:8 | 2000 psi |

| Residential Slab | 1:2:4 | 3000 psi |

| Reinforced Column | 1:1.5:3 | 3500–4000 psi |

| Heavy Beam/Slab | 1:1:2 | 4500–6000 psi |

This table illustrates a clear comparison for structural engineers.

Example Proportions by Strength Level

- 3500 psi concrete mix ratio (nominal): 1:2:3

- 4000 psi mix ratio: 1:1.5:3

- 4500 psi mix ratio: 1:1:2.5

- 6000 psi concrete mix ratio: 1:1:2 with silica fume, admixtures

The mix groups ratio shows how concrete shifts from lean mixes to dense, high-strength designs.

Comparing Concrete Mix Design 3300 vs 3500

The common question is about the concrete mix design: 3300 vs. 3500. The difference lies mainly in cement content and water-cement ratio. 3500 psi provides a safer margin for columns, beams, and slabs, while 3300 psi may suffice for driveways and light loads.

Use of Photos in Concrete Mix Design Ratio

Contractors and engineers often rely on photos of mix design charts for guidance. These visuals illustrate the volumes of cement, sand, gravel, and water needed for each psi class, making it easier for on-site execution.

Mix Ratios for Housing vs Industrial

The psi ratio for concrete mix used in housing typically ranges between 3000 and 3500 psi. Industrial projects typically use a concrete mix with a psi range of 4500 to 6000 for added reliability.

Residential foundations → 3000–3500 psi.

Industrial floors → 4500–5500 psi.

Concrete for bridges, dams, and hig These structures should be at least 6000 psi.

Starter Concrete Ratio

For construction joints and the first layers, a common starter concrete ratio is 1:2:4 or 1:1.5:3. This ensures a strong bond between the old and new concrete layers.

Concrete remains the most adaptable material in civil engineering, and choosing the right cement mix ratio is key to lasting strength and safety.

Frequently Asked Questions (FAQ) on Concrete Mix Ratio

Q1. What is the best concrete mix ratio for 3500 psi concrete?

The most common 3500 psi concrete mix ratio is 1:2:3 (cement: sand: gravel). It provides high strength, making it ideal for residential footings, walls, and columns.

Q2. What is the difference between a nominal mix ratio and a design mix ratio?

A nominal mix ratio follows fixed proportions like 1:2:4, while a design mix ratio is calculated scientifically to achieve targeted strengths such as 3500, 4000, or 6000 psi concrete.

Q3. What are the standard ratios of rebar to concrete for footings at abutments?

Standard footing mixes typically use 1:2:4 or 1:1.5:3 (close to a 3500 psi mix ratio) when reinforcement like rebar is included for foundation and abutment strength.

Q4. What is the high-strength concrete mix ratio for 6000 psi?

A 6000 psi concrete mix ratio is usually 1:1:2, with special admixtures like silica fume and a low water-cement ratio to achieve maximum durability.

Q5. Is 3000 psi or 3500 psi concrete better for housing?

Both are suitable, but 3000 psi and 3500 psi mix ratios are commonly used. For driveways and light slab loads, 3000 psi is sufficient, but 3500 psi is preferred for footings, slabs, and reinforced concrete in residential structures.

What is the concrete mix ratio?

The concrete mix ratio indicates the proportion of cement, sand, and aggregate used to create concrete.It is the combination of these ingredients that gives concrete its unique properties.

Cement acts as the binding agent, or glue, that holds the mixture together when it is mixed with water.

Sand provides workability and a uniform particle size for concrete.

Aggregates, such as gravel and crushed stone, contribute to the volume and dimensional stability of the mixture.

The proportions of these ingredients determine the strength, durability, and water resistance of the concrete. Concrete mix ratios are often specified based on the type of construction project and conditions the concrete will be exposed to.

Types of Concrete Mix Ratios

There are two main types of concrete mix ratios:

Nominal Mix Ratios

In a nominal mix ratio, the amounts of cement, sand, and aggregate are predetermined. Nominal mix ratios specify concrete mixes by volume, utilizing standard shovel or bucket sizes. Common nominal mixes are:

- M15 (1:2:4)—This mix has 1 part cement, 2 parts sand, and 4 parts aggregate. It results in approximately 2175 psi concrete used for standard construction projects.

- M20 (1:1.5:3)—This nominal mix ratio contains more cement and is stronger, with a psi around 3000. It’s suitable for more demanding applications.

- M25 (1:1:2)—This ratio yields high-strength concrete of 6000 psi and is used in heavy construction projects.

The strength of the nominal mix concrete varies widely for given workability due to variation of mix ratio. M15 and M20 are considered nominal mixes of concrete.

Design Mix Ratios

Design mix ratios are calculated based on desired concrete properties, like strength and water content. The proportions are determined using quality-controlled materials to optimize performance.

Design mixes allow for greater control over the characteristics of concrete. They require testing samples to verify that the proportions meet specifications before being used in the field.

Standard Concrete Mix Ratios

A nominal mix of fixed ratios shows variation in strength, resulting in an over-rich or poor So the minimum compressive strength is assigned in many proportions and termed the “standard mix.” As per IS 456:2000, M25, M30, M35, and M40 are termed as standard mixes. Some standard mixes for different applications include:

- Foundations—1:2:4, 4000 psi

- Slabs, driveways—1:2:3, 3000–3500 psi

- Footings—1:3:6, 2500–3000 psi

- Walls – 1:1:2, 6000 psi

- Patios—1:2:3, 3000–3500 psi

- Sidewalks—1:2:3, 3000–3500 psi

These standard ratios serve as a starting point based on common applications. The actual mix can be adjusted as needed to achieve the desired properties of the concrete.

High-Strength Concrete Mix Ratios

For applications requiring very durable, high-strength concrete, special mix designs are used with higher cement proportions:

- Foundations—1:1.5:3, 6000 psi

- Bridges, parking garages—1:1:2, 10,000+ psi

- Marine projects—1:1.5:3, 6000–8000 psi

The extremely high-strength mixes have enhanced durability but also higher material costs. They are specified only when needed based on the structural loads and environment.

Factors Affecting Concrete Mix Design

Several factors influence the ideal concrete mix ratio:

- Strength—Higher compressive strength requires more cement, which increases cost. Only add extra cement if needed.

- Workability—More sand provides better workability for placing and finishing concrete. Excess sand reduces strength.

- Water content—More water improves workability but reduces strength. Use the minimum amount needed.

- Durability—Harsher environments call for low water-cement ratios and air-entraining agents.

- Aggregate size—Bigger aggregate dimensions reduce shrinkage but can hamper workability.

- Slump—Slump tests measure concrete workability. A high slump allows lowering the water content.

- Exposure—Concrete exposed to freezing, salt, or dampness requires higher strength and water resistance.

Proper concrete takes into account all these factors to determine the optimal balance. Testing trial batches helps determine the correct proportions.

Benefits of Using the Right Concrete Mix Ratio

Setting the concrete mix ratio correctly provides many benefits for construction projects:

- Ensures concrete meets the required compressive strength specifications

- Provides adequate workability for placing and finishing concrete

- Minimizes shrinkage cracking due to excess water content

- Provides proper water resistance and durability for the environment

- Optimizes the cost by preventing over-use of expensive cement

- Produces quality concrete that lasts for the service life of the structure

In summary, selecting the correct concrete mix ratio is crucial for ensuring structural integrity, preventing premature failures, and minimizing problems such as cracking and crumbling in concrete work. With the right mix design, concrete structures can endure over time and offer lasting value.

Key Takeaways on Concrete Mix Ratios

- Concrete mix ratio refers to the ratio of cement, sand, and aggregate in the concrete mixture.

- Nominal and design mix ratios are the two main types of concrete mix ratios.

- Standard mix ratios provide a general guideline for concrete used in common applications.

- Factors like strength, workability, water content, and the environment impact the ideal mix ratio.

- Properly designed concrete mix ratios are crucial for achieving the strength, durability, and quality needed on construction projects.

Using the right concrete mix ratio ensures you get a workable, strong, and long-lasting concrete mix for your construction project needs.