Elastic materials are substances that can stretch or deform when a force is applied, but then return to their original shape once the force is removed.

These materials have the useful property of elasticity, which enables them to undergo reversible deformation.

Some common examples of elastic materials include rubber bands, bungee cords, stretchy fabrics like spandex, and springs.

The elastic behavior of materials occurs at the molecular level.

When an elastic material is stretched, the molecular chains align and stretch as well, storing potential energy.

When the stretching force is released, these molecular chains recoil back to their original, coiled state, releasing the stored energy.

The degree of elasticity depends on factors like molecular structure and the strength of intermolecular forces.

The study of the elastic properties and deformations of materials is known as “elasticity theory” in physics and engineering.

By understanding the mechanics and limitations of elastic deformation, researchers have been able to develop many useful applications and products, from flexible bridges to high-performance athletic shoes.

At the same time, exploring when elastic deformation crosses over into permanent plastic deformation, when the material cannot return to its original form has equally important implications for creating safe structures and designs.

Civil engineers use a wide array of construction materials in their projects, ranging from concrete and steel to timber and polymers.

Many of these critical engineering materials exhibit elastic behavior under various loading conditions before ultimately failing.

This refers to their ability to undergo reversible deformation within certain limits when external stresses are applied.

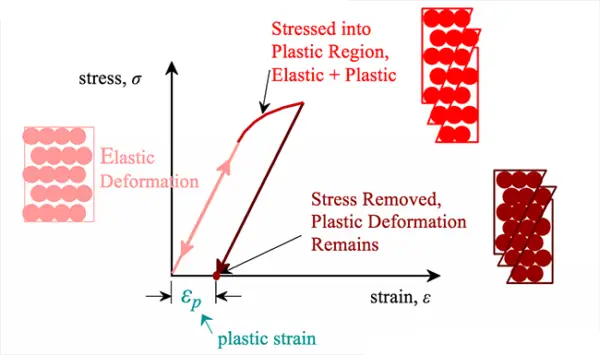

Once loads cause stresses to exceed the proportional limit and elastic range however, permanent or plastic deformation can begin.

Understanding the characteristics, types, testing methods and major applications of elastic engineering materials is key.

Types of Elastic Materials

Many materials show elastic properties up to a yield point including metals, alloys, polymers, composites, wood, and to some degree, concrete.

Natural rubber demonstrates exceptional elasticity, capable of over 500% strain recovery.

Engineered elastomers like neoprene, polyurethane, and flexible PVC also exhibit excellent elasticity traits.

Shape memory alloys like nitinol display specialized elastic deformation abilities when transitioning between crystal phases.

Elastic Materials Examples in Engineering

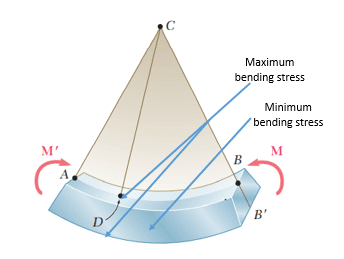

Structural steel components like beams are designed to endure loads primarily within the elastic zone, reversibly bending before unloading.

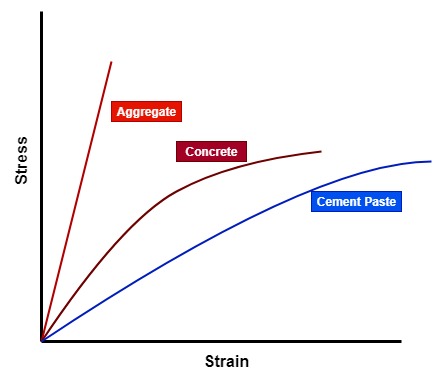

Concrete can also act elastically but has lower modulus values and tends to display plasticity and cracking sooner under tensile loads. Reinforcing steel then bears further stress.

Polymers demonstrate wide-ranging stiffnesses for engineered elastic behavior in polymers springs, seals, gaskets, pads and flexible joints.

Properties of Elastic Materials

The most important material properties related to elastic mechanical response include:

- Young’s Modulus: Indicates stiffness, higher means more rigid

- Shear Modulus: Resistance to shear deformation

- Bulk Modulus: Resistance to compression

- Poisson’s Ratio: Characterizes transverse strain response

- Coefficient of Elasticity: Fractional elastic strain capacity

Testing determines these key elastic parameters.

Elastic Deformation in Materials

Applying small stresses induces elastic deformation through extension or compression of interatomic bonds.

Once stresses are removed, stored elastic energy drives a return to the initial geometric configuration without permanent changes occurring in the material’s microstructure or properties.

Difference Between Elastic and Plastic Materials

Elasticity involves fully reversible deformation. Removal of the load enables the return to original dimensions.

Plasticity means permanent shaping distortions remain even after eliminating the applied stress.

This is due to slip or displacements between atoms themselves.

Elastic behavior precedes plasticity up to a yield point that should not be surpassed in engineering design scenarios or component failure can result.

How to Test Elasticity of Materials

Tensile tests: Gradually apply controlled uni-axial tension until plastic yield initiation and record deformation with strain gauges.

Bending tests: Bend specimens with 3 or 4 point loading and detect deflection amounts.

Impact resilience tests: Measure rebound heights after an elastic collision with a heavy pendulum weight.

Hardness tests: Indentation methods reveal depth and deformation levels.

Dynamic Mechanical Analysis: Applies oscillatory loads while scanning temperature.

Elastic Materials Used in Construction

Concrete: Displays limited short-term elasticity in compression before inelasticity begins.

Structural steel: Careful design restricts maximum stresses to elastic range under dead, live and wind loads.

Masonry: Mortar joints enable minor elastic deformation capacity.

Timber framing: Flexes elastically first before exhibiting brittle failure modes when fibers split.

Elastomers: Used when needing expansion joints between building sections and vibration damping.

Elastic Material Applications

Bridges: Bearings made using elastomeric pads compress and rebound elastically to allow movement.

Buildings: Elastic seismic base isolation systems used below foundation for earthquake resilience.

Electronics: Flexible elastic printed circuit boards survive vibration and shock environments through elasticity.

Implants: Nitinol vascular stents and orthodontic wires exploit special elastic shape memory properties.

Vibration damping: Elastomeric mounts, grommets and bushings all leverage elastic characteristics.

Advantages and Disadvantages of Elastic Materials

Advantages

- Reversible deformation up to yield point

- Return materials to original shapes repeatedly

- Store and release significant elastic energy

Disadvantages

- Limited recoverable strain levels

- Eventual plastic failure likely after repetitive cycling

- Difficult to model complex real-world elastic behavior

Elasticity Equations and Calculations

Stress and strain formulas like these below enable modeling and designing elastic components:

σ = Eε

σ = stress (Pa, psi)

E = Elastic modulus (Pa, psi)

ε = strain (m/m, in/in)

Incorporating ν, shear moduli terms provides more advanced analysis.

This has provided a high-level introduction into elastic engineering materials. There are many nuances around optimizing elastic responses across different material systems in civil infrastructure design scenarios.